Universal type stir-frying device used for tea and operating method for universal type stir-frying device

A general-purpose, tea-leaf technology, applied in the field of food processing, can solve the problems of small scope of application, poor versatility, and low work efficiency, and achieve the effects of increasing the scope of application, reducing labor intensity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

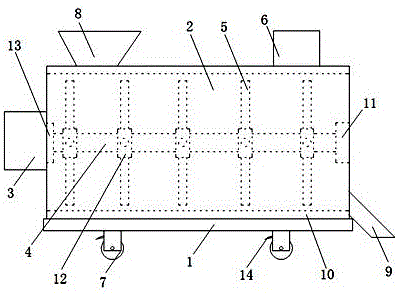

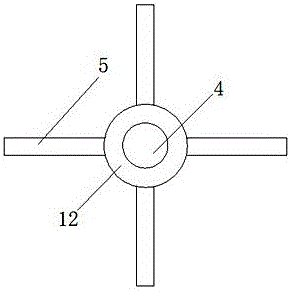

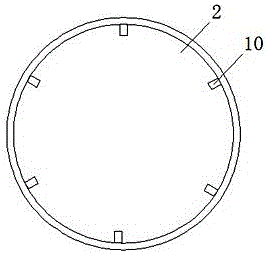

[0021] as attached Figure 1-3 As shown, a general-purpose stir-fry device for tea leaves includes a base plate 1, a drying chamber 2, a motor 3, a transmission shaft 4, a stirring rod 5, a blower 6 and a walking wheel 7, and it is characterized in that the drying chamber 2 is arranged on the bottom plate 1, and the feeding bin 8 and the discharge pipe 9 are arranged on the drying chamber 2, and a baffle 10 and a heating block 11 are arranged on the inner wall of the drying chamber 2, and the number of the baffles 10 is 6, the motor 3 is arranged on the outer wall of the drying chamber 2, the transmission shaft 4 is arranged in the drying chamber 2, one end is connected with the motor 3, the other end is connected with the heating block 11, and on the transmission shaft 4 A heat conduction block 12 is provided, and a thermal insulation ring 13 is provided at the joint between the motor 3 and the transmission shaft 4, through which heat insulation ring 13 is used to prevent hea...

Embodiment 2

[0028] as attached Figure 4 As shown, a general-purpose stir-frying device for tea leaves includes a base plate 1, a drying chamber 2, a motor 3, a transmission shaft 4, a blower 6, a walking wheel 7 and an auger 15, and it is characterized in that the drying chamber 2 is arranged on the bottom plate 1, and the feeding bin 8 and the discharge pipe 9 are arranged on the drying chamber 2, and a baffle 10 and a heating block 11 are arranged on the inner wall of the drying chamber 2, and the number of the baffles 10 is 8, the motor 3 is arranged on the outer wall of the drying chamber 2, the transmission shaft 4 is arranged in the drying chamber 2, one end of which is connected to the motor 3, and the other end is connected to the heating block 11, and the motor 3 is connected to the heating block 11. The connection of the transmission shaft 4 is provided with a heat insulation ring 13, which prevents heat from being transmitted to the motor 3 through the heat insulation ring 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com