Fresh-keeping production equipment for food with stuffing

A technology for production equipment and food, applied in food preservation, coating of food, preservation of food ingredients as anti-microbials, etc., can solve the problems of increased storage, logistics energy consumption, inability to replicate in a large area when opening a store, and high labor costs. Achieve large-scale automated production, facilitate large-scale automated production, and enhance corporate profitability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

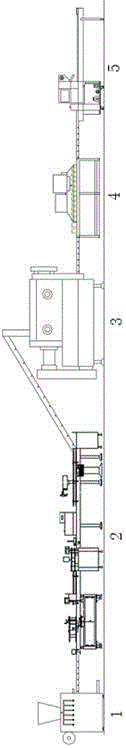

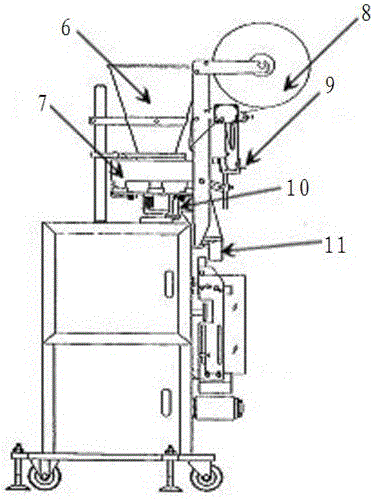

[0017] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises stuffing machine 1, and the outlet of stuffing machine 1 is connected material arrangement device 2 by conveyor belt, and material arrangement device 2 is connected the unloading riser of dumpling machine 3 tops by conveyor belt, and the wrapping device outlet of dumpling machine 3 bottoms is provided with Connect the conveyor belt of the automatic pan machine 4, the automatic pan machine 4 is connected to the packaging machine 5 through the conveyor belt; the top of the stuffing machine 1 is provided with a feeding funnel 6, and the bottom is equipped with a film feeding roller 8, and the feeding funnel 6 passes through the screw Connect the subordinate pipeline 7, the mouth of the subordinate pipeline 7 is provided with a pump type pusher 9 and a corresponding cutter 10, the edible film heat sealing device 11 connected to the film feeding roll 8 is arranged below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com