An integral carpet cleaning machine

A carpet cleaning machine and integrated technology, applied in the direction of carpet cleaning machine, carpet cleaning, cleaning machinery, etc., can solve the problems of low cleaning efficiency and incomplete cleaning, and achieve the effect of convenient operation, saving energy and manpower, and thorough brushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

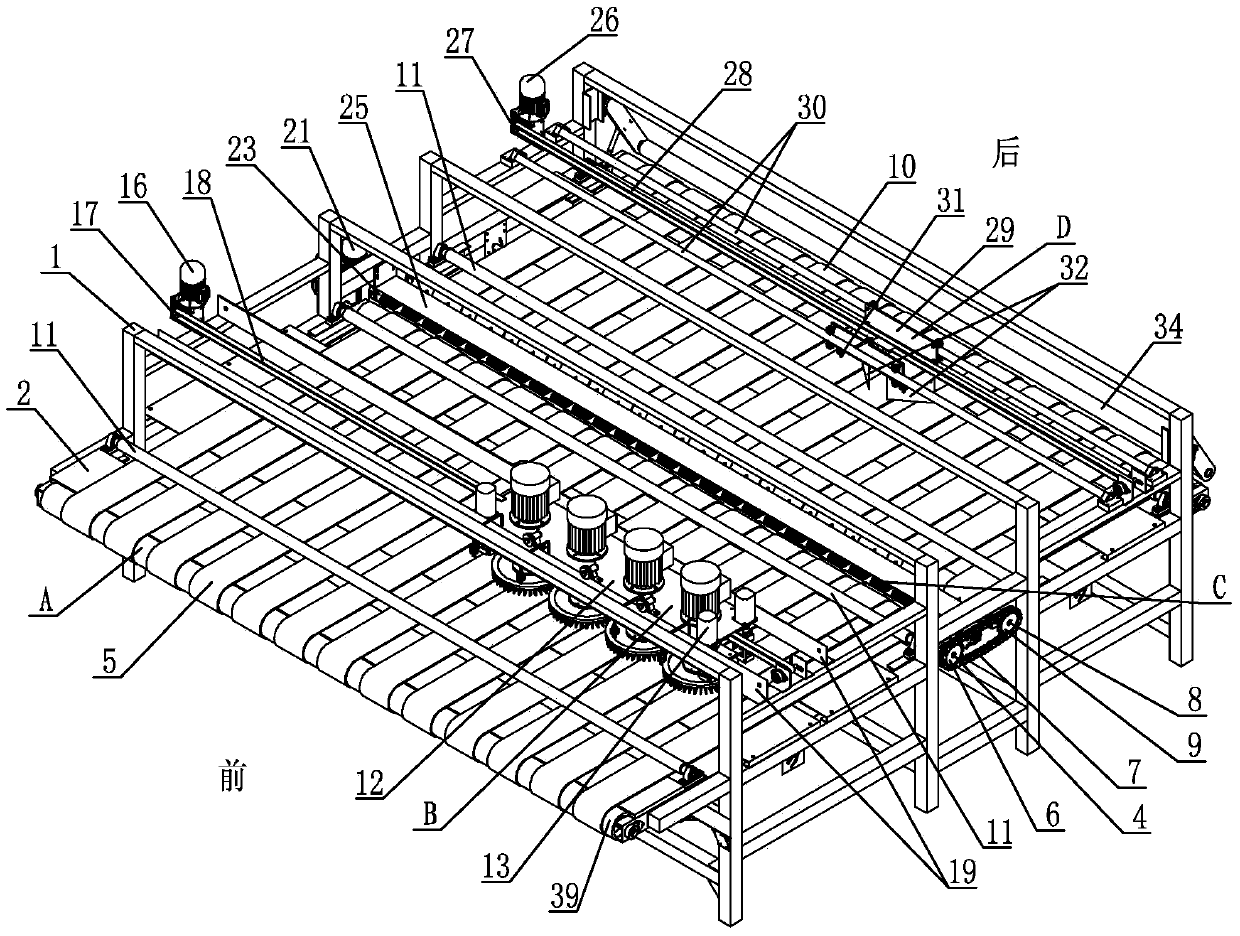

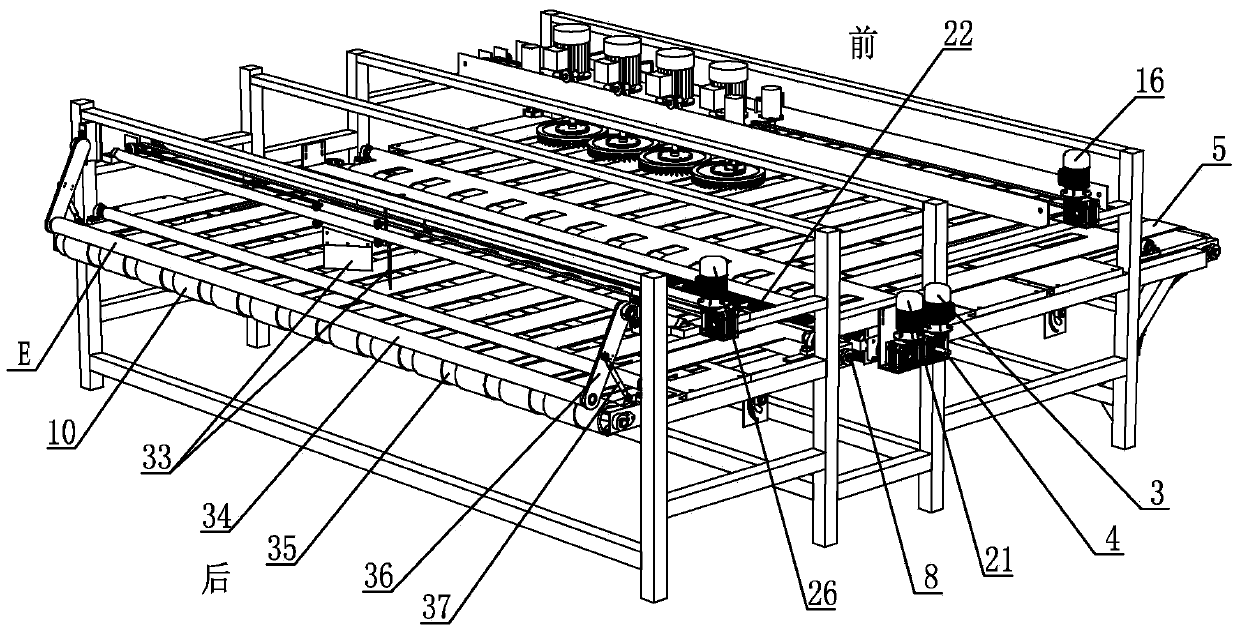

[0016] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment. This embodiment includes a transmission mechanism A, a brushing mechanism B on the fur side, a brushing mechanism C on the back side, a wiper mechanism D on the fur side, and a rolling blanket mechanism E. The transmission mechanism A includes a frame 1, a front bracket 2, a chain Transmission reduction motor 3, transmission driving shaft 4, primary conveyor belt 5, driving sprocket 6, chain 7, transmission driven shaft 8, passive sprocket 9, secondary conveyor belt 10, multiple pressure rollers 11, transmission driving shaft 4 and Transmission driven shaft 8 is arranged in the middle part of frame 1 in parallel, and front support shaft 39 and rear support shaft 35 are respectively arranged on the front and rear ends of frame 1, and the two ends of front support shaft 39 are affixed with front bracket 2, and rear support The two ends of the shaft 35 are fixedly connected with the...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 and figure 2 To describe this embodiment, two pressure rollers 11 are provided on the primary conveyor belt 5 of this embodiment, and two pressure rollers 11 are provided on the secondary conveyor belt 10 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

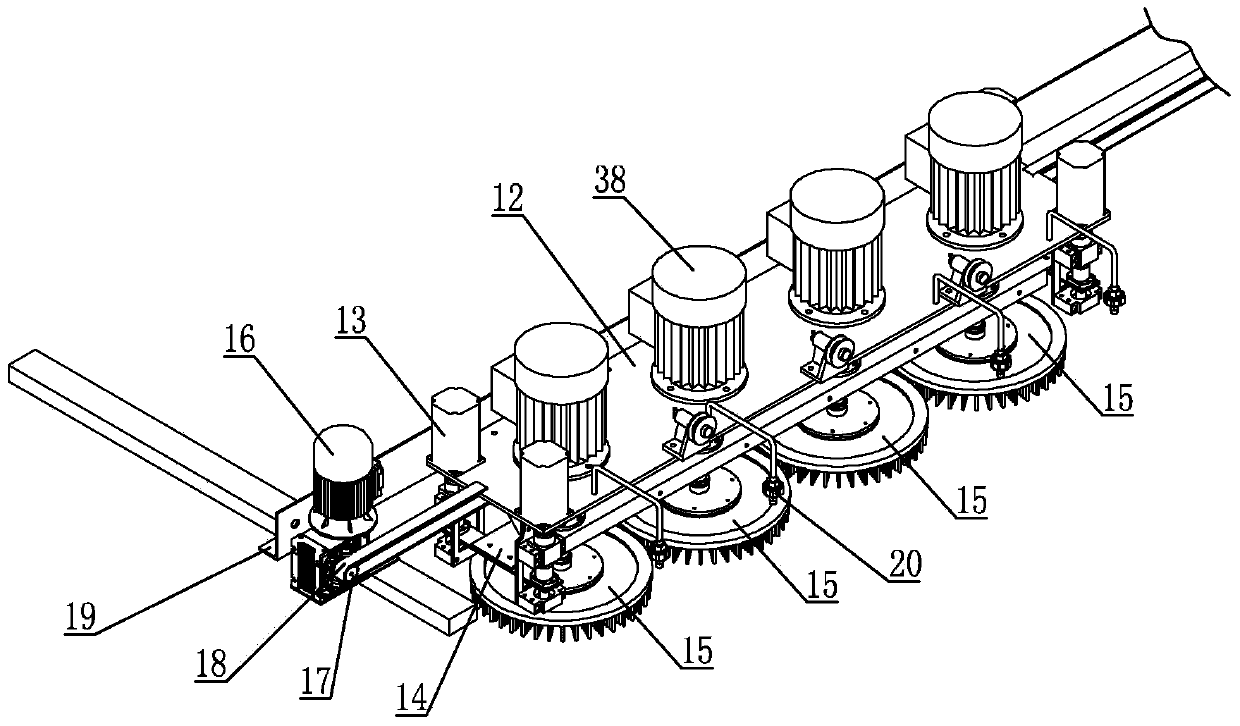

[0018] Specific implementation mode three: combination image 3 Illustrate this embodiment, the hair surface brushing mechanism B of this embodiment comprises brush holder 12, stepper motor 13, brush head synchronous lifting platform 14, belt transmission deceleration motor 16, two hair surface brush synchronous pulleys 17, hair surface brush Synchronous belt 18, two brushing linear guide rails 19, multiple spraying devices 20, multiple brush heads 15 and multiple brush head reduction motors 38, two brushing linear guide rails 19 are arranged in parallel, and brush holder 12 is horizontally arranged on Between the two brushing linear guide rails 19, the brush head synchronous lifting platform 14 is arranged under the brush frame 12, the brush head synchronous lifting platform 14 is fixedly connected with the brush frame 12, and the brush head synchronous lifting platform 14 is connected with the stepping motor 13 , the stepper motor 13 is fixed on the brush holder 12, a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com