A kind of porous foam nozzle used in the improvement test of dregs in shield construction

A technology of muck improvement and porous foaming, which is applied in the direction of spraying devices and liquid spraying devices, can solve the problems of affecting test results, foam expansion rate, half-life performance indicators are not easy, and the effect of soil improvement is greatly affected. Achieve the effect of improving efficiency and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

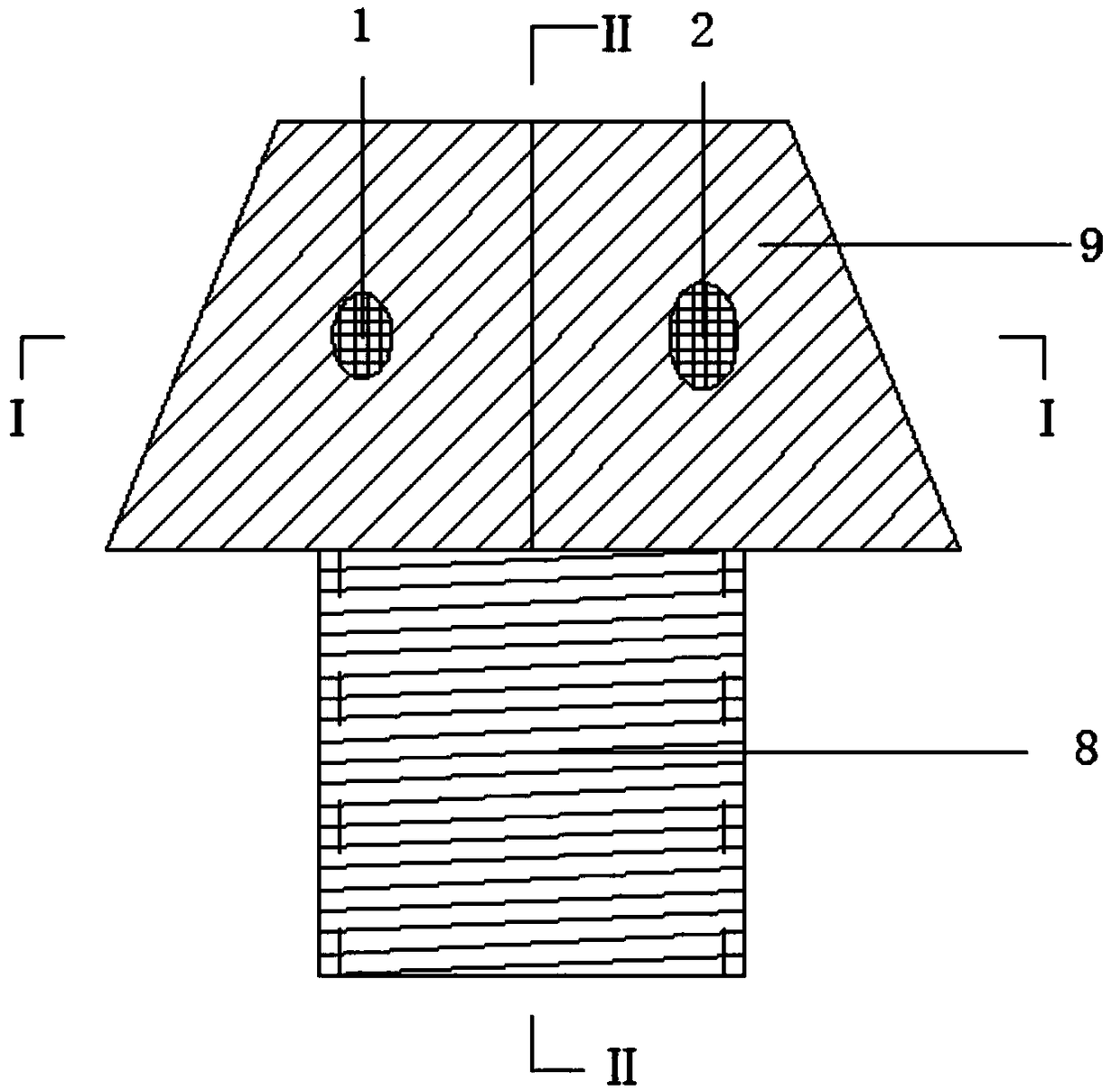

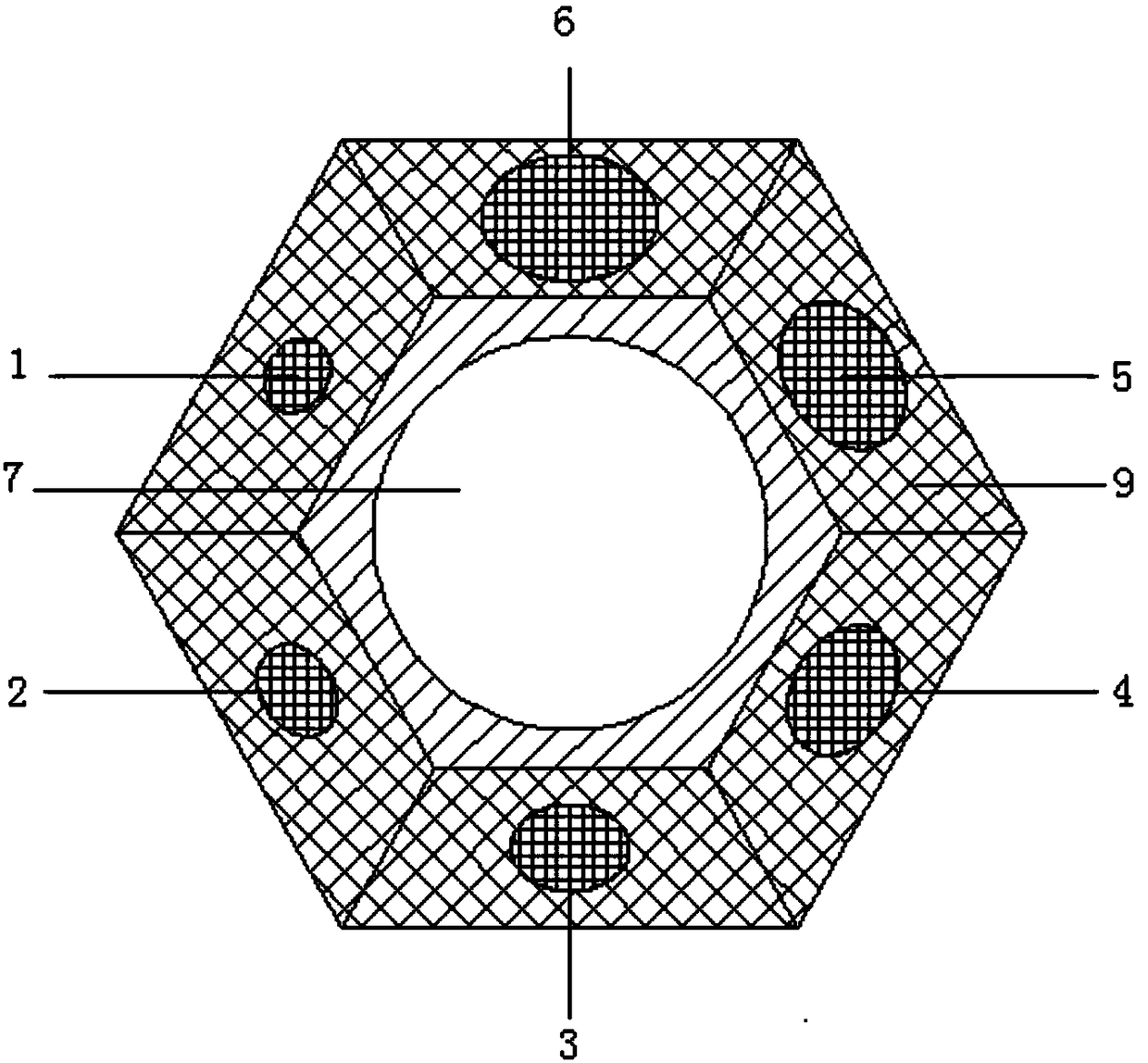

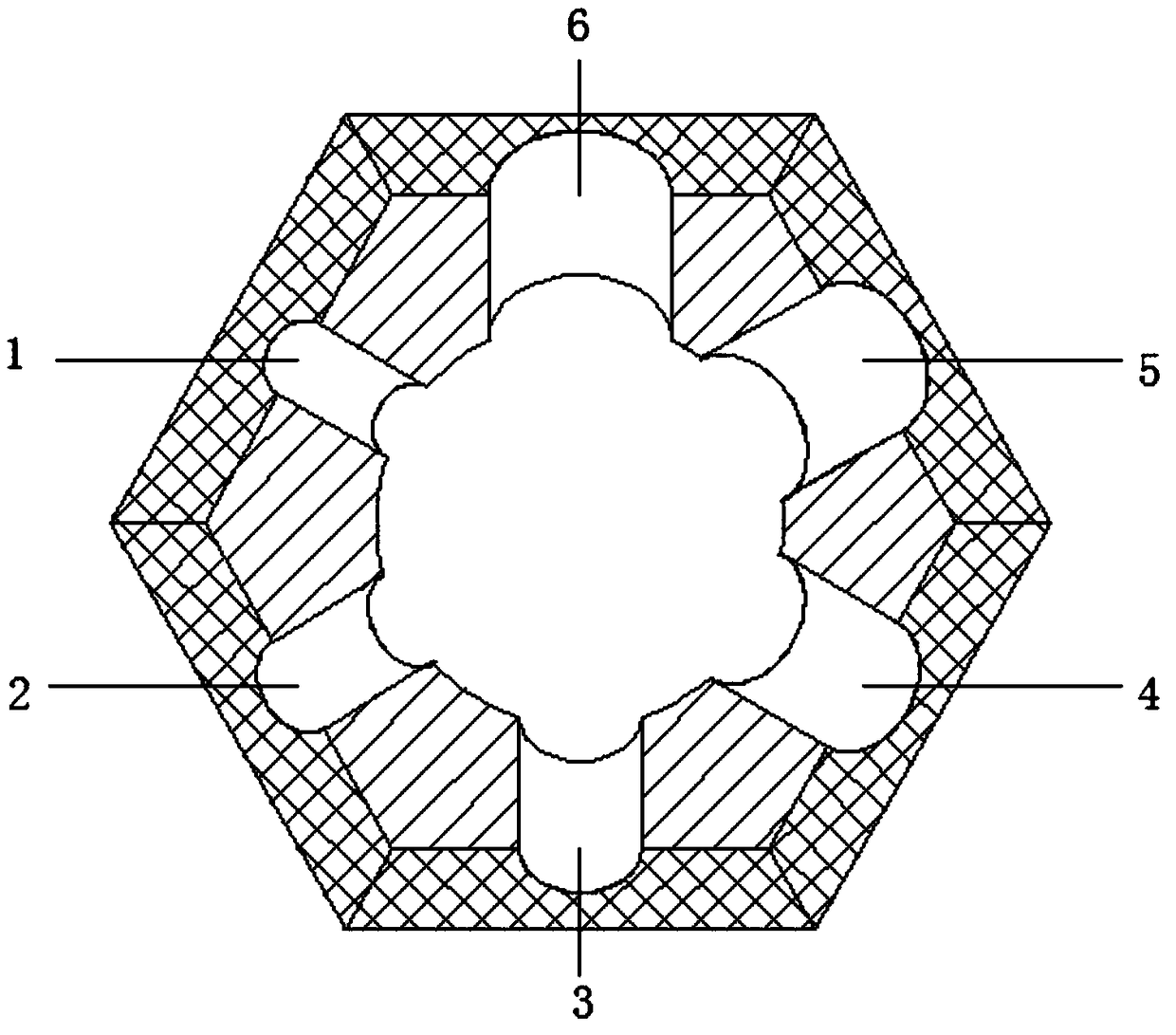

[0026] Attached below Figure 1-8 And in conjunction with example the present invention is described in further detail.

[0027] The porous foam nozzle used for the improvement test of slag in shield construction, including the main body of the porous foam nozzle, the lower part is a steel pipe 8 with threads, which is used to connect the main pipe for circulating liquid, and the upper part is the upper narrow lower part. The wide nozzle body 9 has six nozzles with six different apertures on the six sides of the nozzle. The edge of the nozzle is connected with a net cover. The net cover has a variety of apertures to choose from. The liquid is sprayed out through the net cover and contacts with air to form foam.

[0028] The upper surface of the spray head entity 9 is provided with a circular hole 7 for inserting the rotary switch 10 .

[0029] The steel pipeline 8 can be tightly connected with the main liquid pipeline.

[0030] The six nozzles with different apertures on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com