A kind of small-pore polymethacrylimide foam and preparation method thereof

A technology of polymethacrylimide and methacrylic acid, applied in the field of small-pore polymethacrylimide foam and its preparation, to achieve high-temperature dimensional and weight stability, good machinability, and glue absorption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

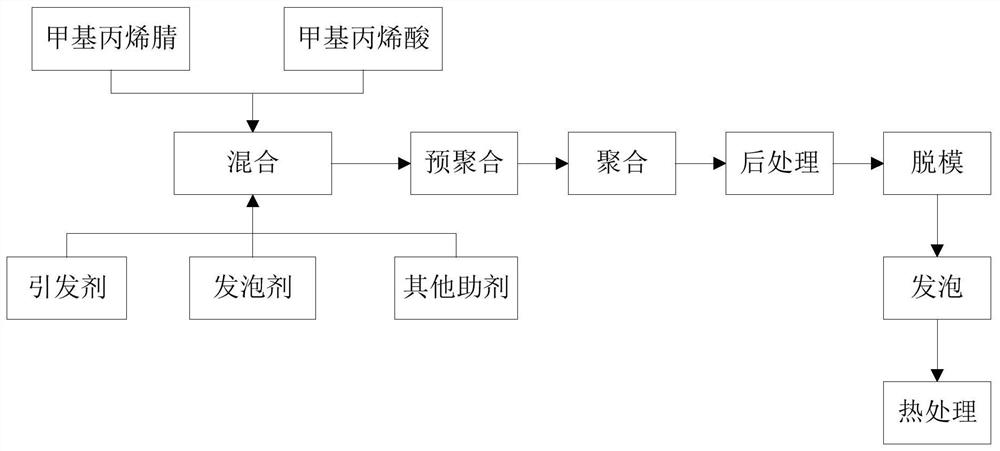

[0046] Such as figure 1 Shown, the preparation method of the small-pore polymethacrylimide foam provided by the invention comprises the steps:

[0047] Step 1, using methacrylic acid and methacrylonitrile as monomers in parts by weight, adding an initiator, a crosslinking agent, a foaming agent and other reagents, and mixing uniformly to obtain a mixed solution;

[0048] Step 2, pouring the mixed solution into a mold, and performing free radical polymerization in a temperature environment of 30°C to 50°C to obtain a pre-polymerized resin plate;

[0049] Step 3, subjecting the pre-polymerized resin board to pre-treatment, demoulding, and post-treatment to obtain a foamable resin board; wherein, the pre-treatment and post-treatment are carried out as follows: the pre-polymerized resin board is heated to 50-80°C and keep for 4-6h, then raise the temperature to 85-100°C and keep for 5-7h, then raise the temperature to 105-115°C and keep for 1.5-3.5h;

[0050] Step 4, heating and...

Embodiment 1

[0082] The following components are used in parts by weight: 20 parts of methacrylic acid, 50 parts of methacrylonitrile, 2 parts of acrylamide, 0.12 parts of initiator, 3 parts of crosslinking agent, 4.5 parts of foaming agent, 2 parts of nucleating agent, 0.8 parts of mold release agent, 1.2 parts of secondary auxiliary agent, wherein, initiator is the combination of dibenzoyl peroxide, lauryl peroxide, dicarbonate peroxide and tert-butyl peroxybenzoate, the four The mass ratio is 2:2:3.5:2.5, the crosslinking agent is tert-butyl methacrylate and magnesium methacrylate, and the mass ratio of the two is 40:1, and the blowing agent is formamide, tert-butyl alcohol , the combination of isopropanol, the mass ratio of the three is 9:6:1, and the secondary auxiliary agent is the mixture of aliphatic ester surfactant and anisole peroxide;

[0083] Adopt the following method to prepare small-pore polymethacrylimide foam:

[0084] First, mix the above components evenly according to ...

Embodiment 2

[0090] The following components are used in parts by weight: 120 parts of methacrylic acid, 80 parts of methacrylonitrile, 4 parts of N,N-dimethylacrylamide, 0.5 parts of initiator, 6 parts of crosslinking agent, and 12.5 parts of foaming agent , 5 parts of nucleating agent, 2 parts of release agent, 1.5 parts of secondary auxiliary agent, wherein, the initiator is dibenzoyl peroxide, lauryl peroxide, dicarbonate peroxide and tert-butyl peroxybenzoate The combination of esters, the mass ratio of the four is 2.5:2.5:4:1.5, the crosslinking agent is allyl acrylate and zinc methacrylate, and the mass ratio of the two is 15:1, and the foaming agent is formazan The combination of amide, tert-butanol and ethanol, the mass ratio of the three is 8:5:2, and the secondary auxiliary agent is a mixture of metal soap surfactant and benzoquinone;

[0091] Adopt the following method to prepare small-pore polymethacrylimide foam:

[0092] First, mix the above components evenly according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com