A kind of polyurethane foaming agent with enhanced function and preparation method thereof

A technology of polyurethane foaming agent and enhanced function, which is applied in the field of polyurethane foaming agent, and can solve the problems of affecting performance, low storage stability of foaming resin composition, affecting uniformity and dispersibility of microcapsule foaming agent, etc. , to achieve the effect of controlling the foaming rate, controllable foaming and uniform stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

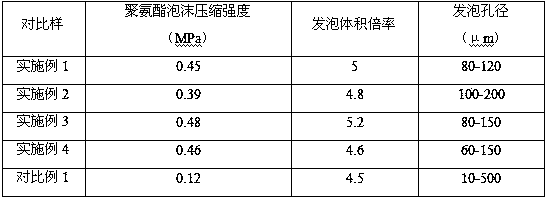

Examples

Embodiment 1

[0027] A polyurethane foaming agent with enhanced functions, comprising ethyl cellulose capsules and a core material wrapped inside ethyl cellulose;

[0028] The core material includes calcium sulfate whiskers and water.

[0029] The core material comprises the following parts by weight of 80 parts of inorganic whiskers and 20 parts of water.

[0030] The weight ratio of the ethyl cellulose capsule to the core material is 1:5.

[0031] A kind of preparation method of the polyurethane blowing agent with enhanced function, comprises the following steps:

[0032] (1) After mixing water and inorganic whiskers evenly, the water and inorganic whiskers can be well loaded and fixed;

[0033] (2) Make ethyl cellulose and solvent into a liquid, and then wrap the prefabricated material in step (1) in a fluidized bed, dry, and age, and the aging time is 5 hours. The aging temperature is 30-40° C. to obtain a microcapsule foaming agent coated with ethyl cellulose and inorganic whiskers ...

Embodiment 2

[0037] A polyurethane foaming agent with enhanced functions, comprising ethyl cellulose capsules and a core material wrapped inside ethyl cellulose;

[0038] The core material includes silicon carbide whiskers and water.

[0039] The core material comprises the following parts by weight of 90 parts of inorganic whiskers and 10 parts of water.

[0040] The weight ratio of the ethyl cellulose capsule to the core material is 1:10.

[0041] A kind of preparation method of the polyurethane blowing agent with enhanced function, comprises the following steps:

[0042] (1) After mixing water and inorganic whiskers evenly, the water and inorganic whiskers can be well loaded and fixed;

[0043](2) Make ethyl cellulose and solvent into a liquid, and then wrap the prefabricated material in step (1) in a fluidized bed, dry, and age. The aging time is 10 hours. The aging temperature is 30-40° C. to obtain a microcapsule foaming agent coated with ethyl cellulose and inorganic whiskers and...

Embodiment 3

[0047] A polyurethane foaming agent with enhanced functions, comprising ethyl cellulose capsules and a core material wrapped inside ethyl cellulose;

[0048] The core material includes zinc oxide whiskers and water.

[0049] The core material comprises the following parts by weight of 85 parts of inorganic whiskers and 15 parts of water.

[0050] The weight ratio of the ethyl cellulose capsule to the core material is 1:15.

[0051] A kind of preparation method of the polyurethane blowing agent with enhanced function, comprises the following steps:

[0052] (1) After mixing water and inorganic whiskers evenly, the water and inorganic whiskers can be well loaded and fixed;

[0053] (2) Make ethyl cellulose and solvent into a liquid, and then wrap the prefabricated material in step (1) in a fluidized bed, dry, and age. The aging time is 20 hours. The aging temperature is 30-40 DEG C, and the microcapsule foaming agent coated with ethyl cellulose and inorganic whiskers and wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com