Industrial fume gas collecting assembly

A technology for collecting gas and dust, applied in the fields of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as easily affecting the breathing health of operators, low dust collection efficiency, etc., to prevent smoke and dust from escaping to the surrounding area. Ambient, the effect of a good capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

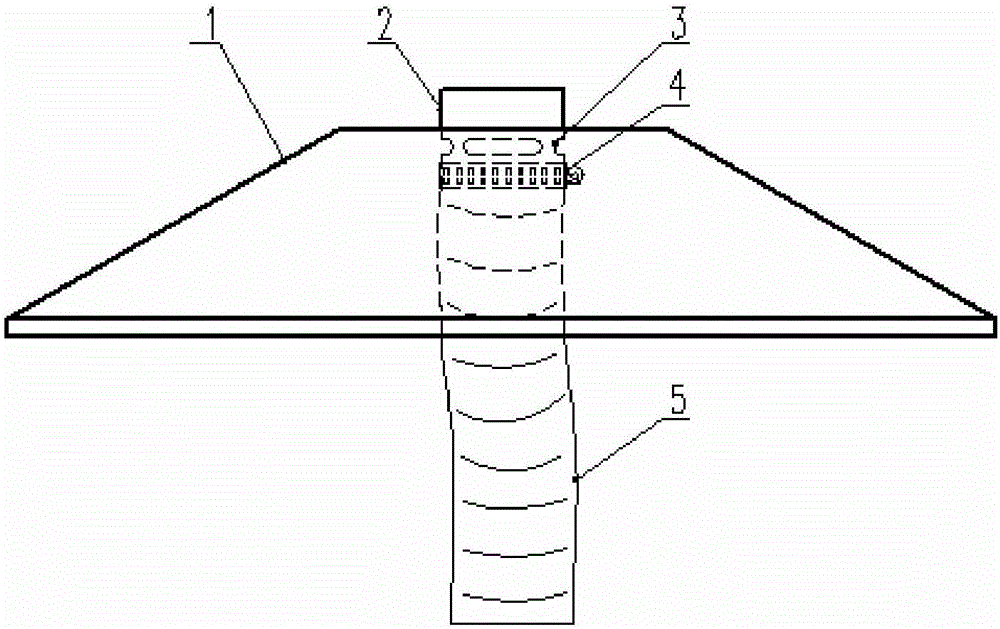

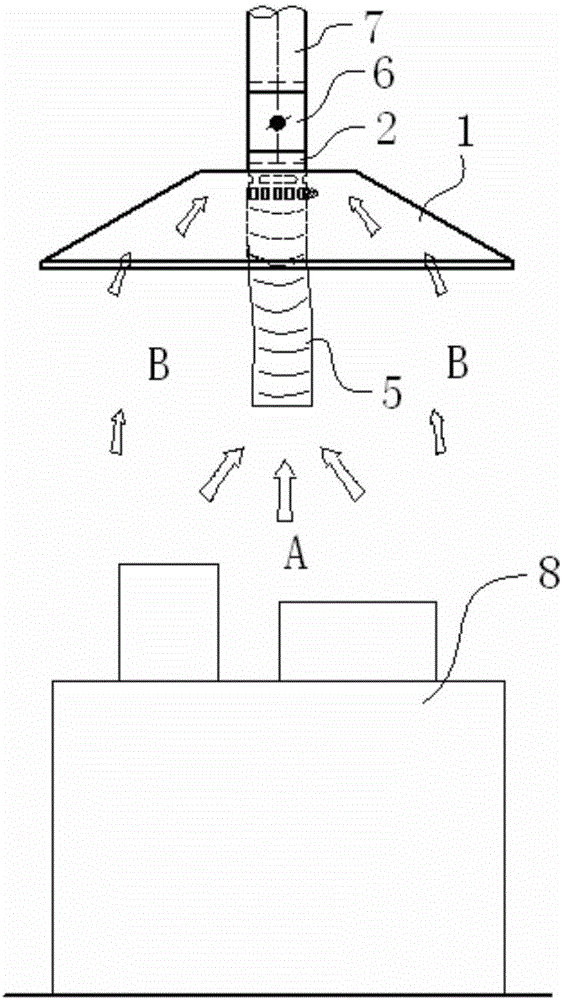

[0022] see figure 1 and figure 2 , the industrial smoke and dust gas collection assembly in the illustration is a preferred embodiment of the present invention, specifically including the gas collection hood 1, the air pipe interface 2, the inner conduit interface 3, the throat clamp 4, the inner conduit 5, the air volume regulating valve 6 and the air duct 7. Among them, the air collecting hood 1 can be a common type of top suction hood, which is fixedly arranged above the working area A of the workbench 8, exceeding the height of the workers, so as not to affect the operation of the workers and equipment around the workbench. The air collecting hood The top of 1 is connected with the air pipe 7 through the air pipe interface 2, and is connected to the fan (not shown in the figure) through the air pipe to trap the smoke gas. The inner duct 5 is connected from the inside of the gas collection hood 1, one end of the inner duct 5 is connected with the air duct of the gas coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com