Arc-shaped screen printing plate, and manufacturing method and printing method thereof

A printing method and a technology of a production method, which are applied in screen printing, screen printing machines, printing, etc., can solve problems such as the influence of printing effects, and achieve the effects of stable and uniform tension and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

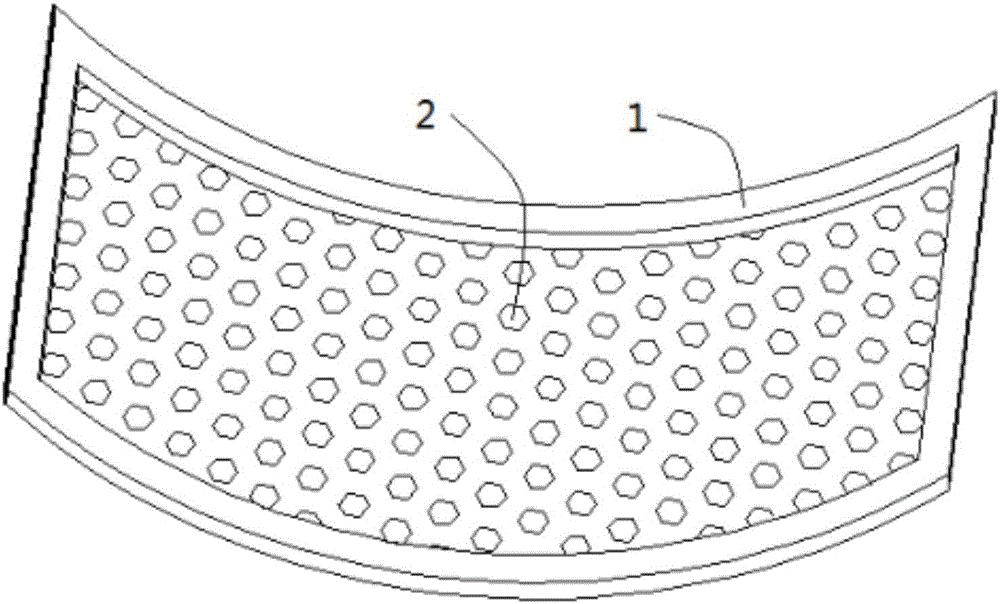

[0030] Such as figure 1 As shown, an arc-shaped screen plate includes a screen frame 1 and a mesh 2, wherein the outer contour of the screen frame 1 is arc-shaped, and the inner arc side of the mesh 2 is glued to the outer arc side of the screen frame 1, and the mesh Frame 1 is made of aluminum alloy. Therefore, the tension of the curved screen plate is stable and even, and because the aluminum alloy profiles can be reused, the cost can be saved.

specific Embodiment approach 2

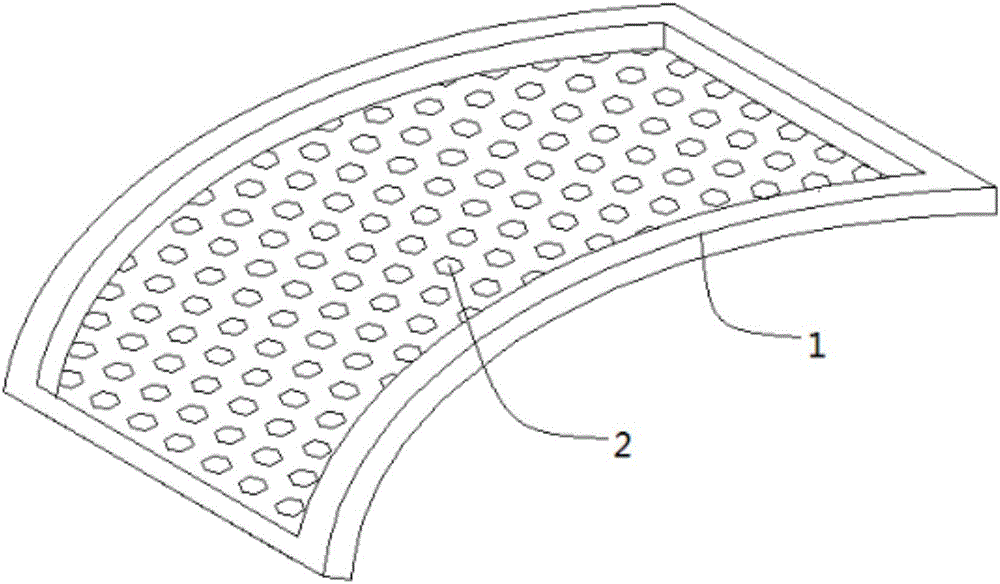

[0031] Such as figure 2 As shown, an arc-shaped screen plate includes a screen frame 1 and a mesh 2, wherein the outer contour of the screen frame 1 is arc-shaped, and the outer arc side of the mesh 2 is glued to the inner arc side of the screen frame 1, and the mesh Frame 1 is made of aluminum alloy. Therefore, the tension of the curved screen plate is stable and even, and because the aluminum alloy profiles can be reused, the cost can be saved.

[0032] The present invention also relates to a method for making the above-mentioned curved screen, which specifically includes the following steps:

[0033] (1) Determine the size of the curved screen, determine the size and tension of the curved screen according to the size of the curved printing product, and then determine the size requirements for making the screen frame material;

[0034] (2) Arc bending, according to the arc size of the arc-shaped printing product, the screen frame material is bent by bending until it compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com