Nested joint for opened conveyer belt

A conveyor belt and nesting technology, which is applied in the field of nested joints of open conveyor belts, can solve problems such as joint failure, low joint strength, and large gaps, and achieve increased strength, long service life, and prevention of separation between teeth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

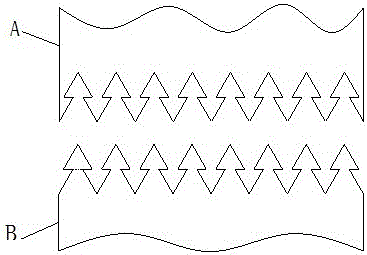

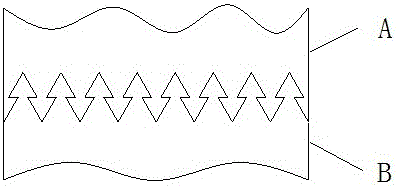

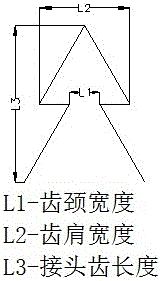

[0013] Such as Figure 1 to Figure 3 As shown, a nested joint of an open conveyor belt, the joint is an arrow-tooth shape, its symmetrical addendum angle is 30 degrees, the width L1 of the tooth neck is 1 / 2 of the width L2 of the tooth shoulder, and the length L3 of the joint tooth is equal to the transmission The minimum turning diameter of the belt is proportional; the two ends of the open conveyor belt, that is, the A end and the B end adopt the same toothing method, and the tooth tips of the A end and the B end can be nested one by one. The thickness of the conveyor belt is 2 mm, and the length L3 of the joint teeth is 120 mm. In this embodiment, the material of the conveyor belt is thermoplastic polyurethane, and polyurethane adhesive is first applied on the flanks of the joints between the A end and the B end, then nested, and then cured to complete the joint.

Embodiment 2

[0015] This embodiment is basically the same as Embodiment 1, except that the symmetrical addendum angle is 45 degrees, the tooth neck width L1 is 3 / 4 of the tooth shoulder width L2, the thickness of the conveyor belt is 3mm, and the joint tooth length L3 is 90mm . In this embodiment, the material of the conveyor belt is polyvinyl chloride, and the polyvinyl chloride adhesive is first applied to the side surfaces of the joint teeth of the A end and the B end, then nested, and then cured to complete the joint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Addendum angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com