Reciprocating material poking device

A reciprocating and mounting frame technology, which is applied in the field of reciprocating material shifting devices, can solve problems such as slow movement, long transportation time, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

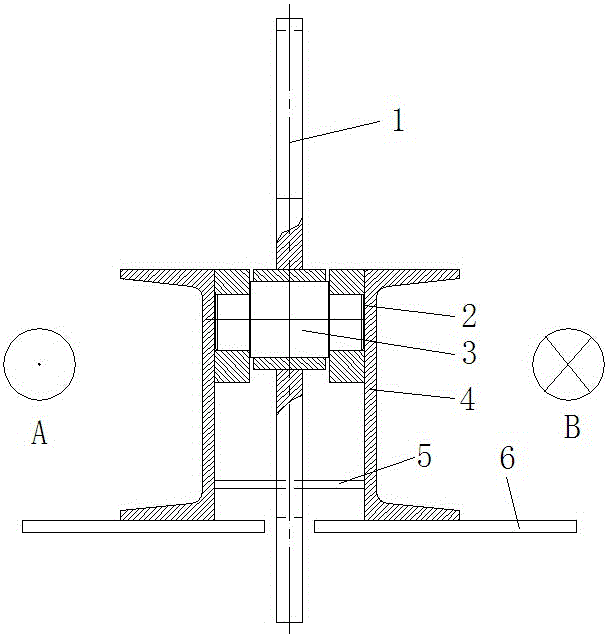

[0018] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0019] Direction A: the outward direction perpendicular to the paper surface; Direction B: the inward direction perpendicular to the paper surface.

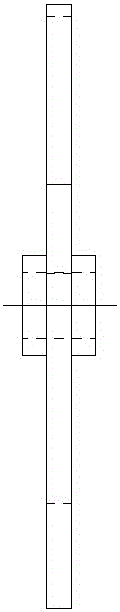

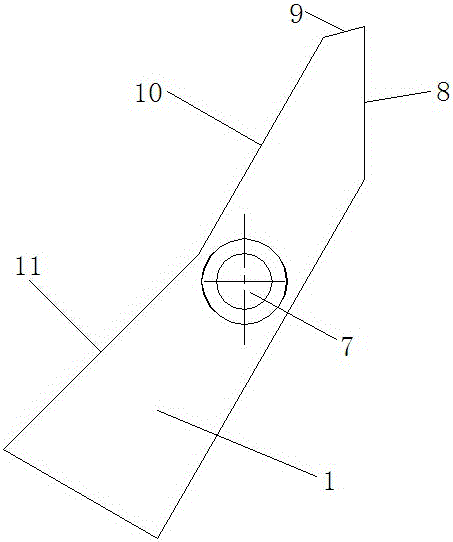

[0020] A kind of reciprocating material shifting device, as shown in the figure, it comprises movable base 6, is fixedly connected with installation frame 4 on described movable base 6, and the top of described installation frame 4 is hinged with finger 1, and the lower part is fixedly connected (such as Welding) There is a horizontal arm 5 for limiting the lower part of the claw 1. The claw 1 is a special-shaped plate, and the middle part of the claw 1 is provided with a hinged hole 7 along its thickness direction. The center line of the hinged hole 7 and the movable base The running direction of 6 is vertical. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com