Automatic unloading and car loading mechanism

A technology of automatic unloading and unloading port, which is applied in the direction of transportation, packaging, loading/unloading, etc. It can solve the problems of uneven loading, heavy weighing, and overflow of raw materials, so as to ensure accurate weighing, prevent dust, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

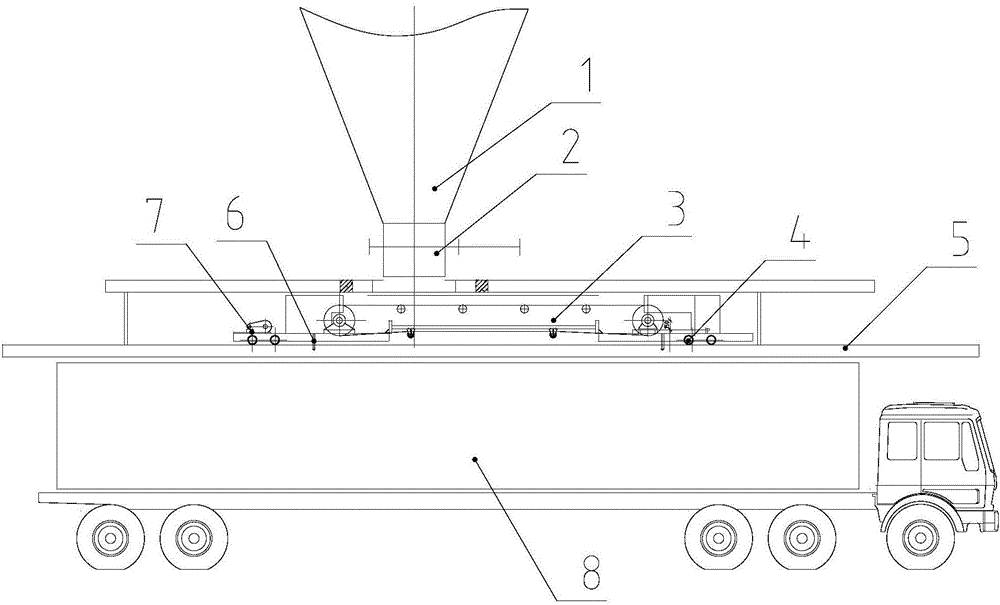

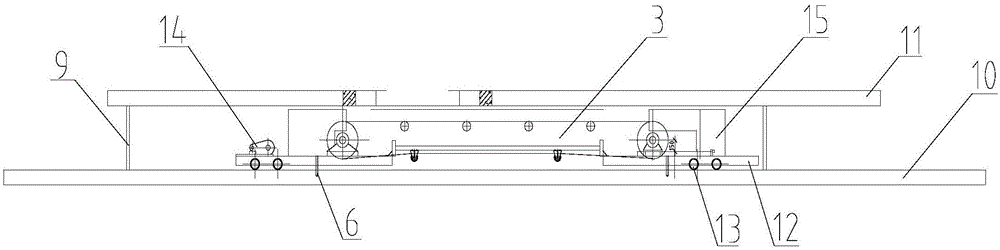

[0020] see figure 1 , figure 2 , The automatic unloading and loading mechanism provided by the present invention includes: a discharge port 1 provided with a valve 2 at the bottom, and the valve 2 adopts a gate valve. Below the discharge port 1 is provided with a belt conveyer 3 for conveying materials, and the belt conveyer 3 is fixed on the belt conveyor traveling device 4;

[0021] The walking hanger 5 is arranged below the discharge port 1, including a track 10, and the two ends of the track 10 are fixed on the platform 11 through the hanger girder 9; . The belt conveyor running device 4 comprises a vehicle frame 12, and wheels 13 are symmetrically arranged on both sides of the bottom of the vehicle frame 12, and the wheels 13 are sequentially connected with a bidirectional reducer and a bidirectional traveling motor 14 through a shaft coupling; the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com