Material loading and unloading platform car of large transport airplane

A technology for loading and unloading platforms and conveyors, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of the maximum lifting height not meeting the loading and unloading requirements, poor maneuverability, and low ground clearance of the chassis, so as to improve the maintenance performance, The effect of reducing the difficulty of pipeline layout and reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

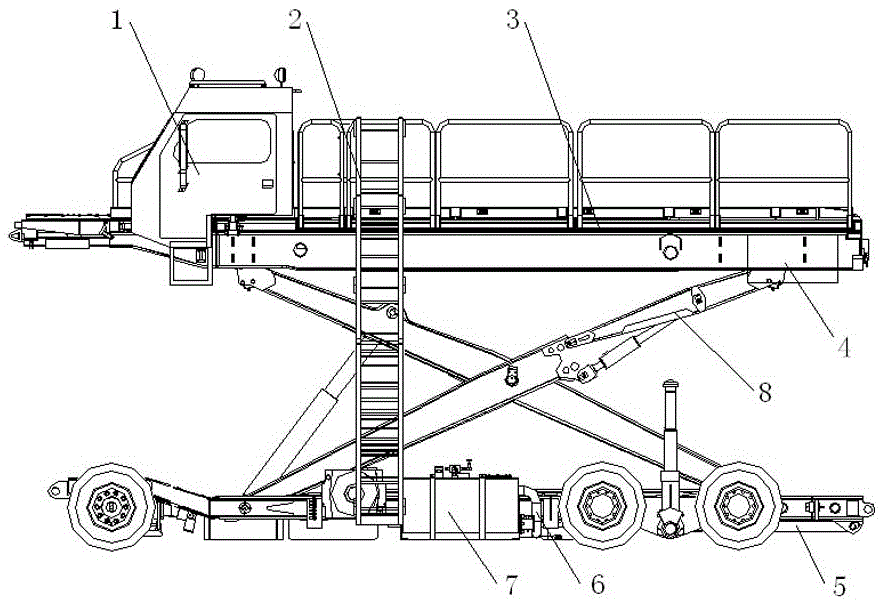

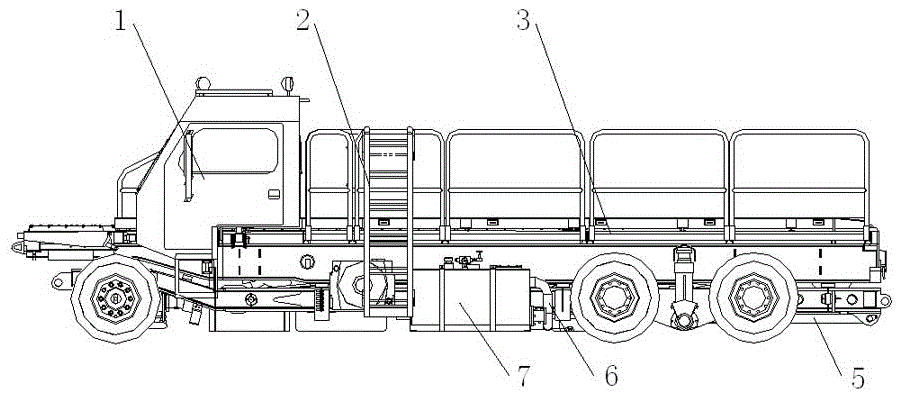

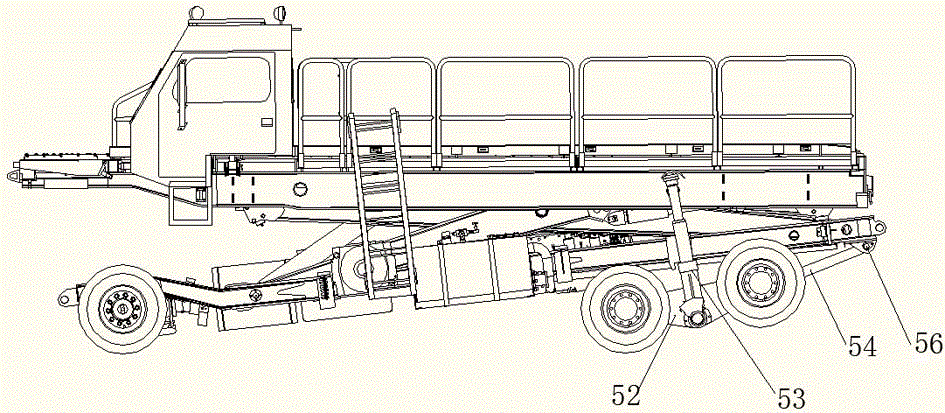

[0021] Such as Figures 1 to 2 A large-scale transport material loading and unloading platform vehicle shown in the figure includes a passable adjustable chassis 5, the chassis 5 is connected to a transmission platform 3 through a posture adjustment device 8, and the front end of the transmission platform 3 is provided with a cab 1, The transmission platform behind the cab 1 is provided with a telescopic ladder 2 connected to the chassis 5, the rear end of the transmission platform 3 is provided with a modular electrical system 4, and the chassis 5 is provided with a power system 6 and a modular The hydraulic system7. The material loading and unloading platform vehicle of the large-scale transport aircraft of the present invention is a hydrostatically driven mobile device, and the whole machine is mainly composed of a cab (control console), a telescopic ladder, a transmission platform, a hydrostatic walking chassis, an attitude adjustment device, a power system, a hydraulic sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com