Multi-rope friction type lifter and first rope replacing method thereof

A replacement method and frictional technology, which is applied to lifting equipment, transportation and packaging in mines, can solve the problems of old steel ropes being entangled with each other, long working hours, and parallel operations, so as to reduce labor intensity and improve efficiency and effectiveness , the effect of high replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below with reference to the accompanying drawings are exemplary, intended to explain the present invention, but not to be construed as limitations of the present invention, those skilled in the art can change the above-mentioned embodiments within the scope of the present invention , modification, substitution and variation.

[0029] The multi-rope friction hoist 100 according to the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

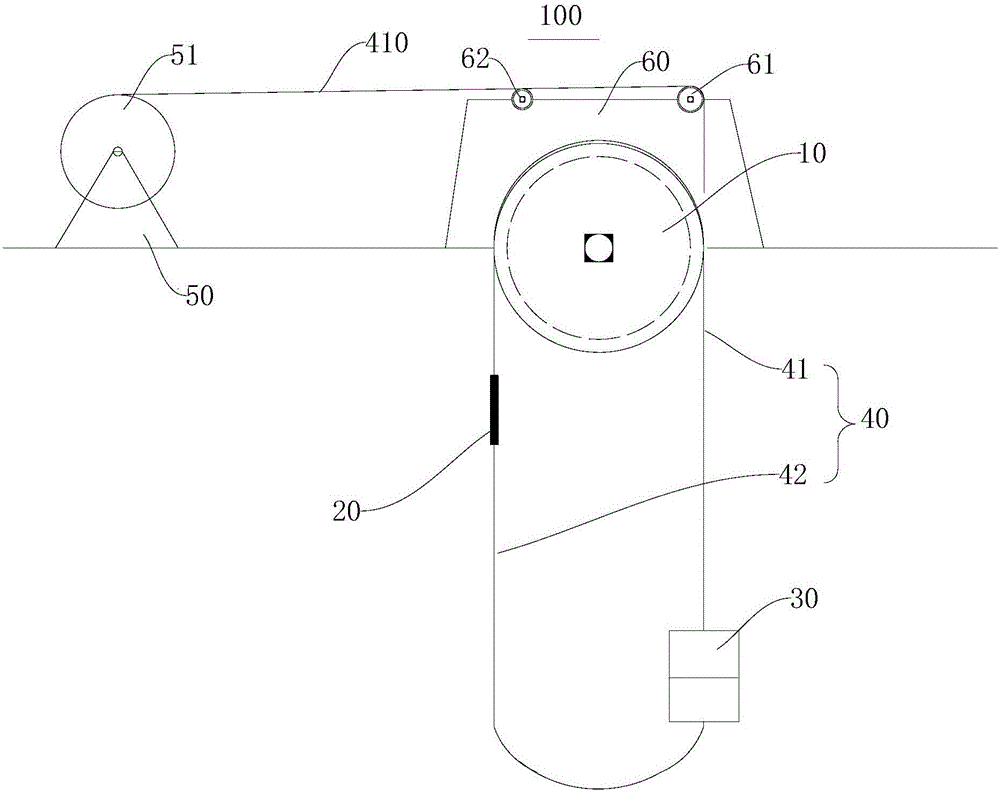

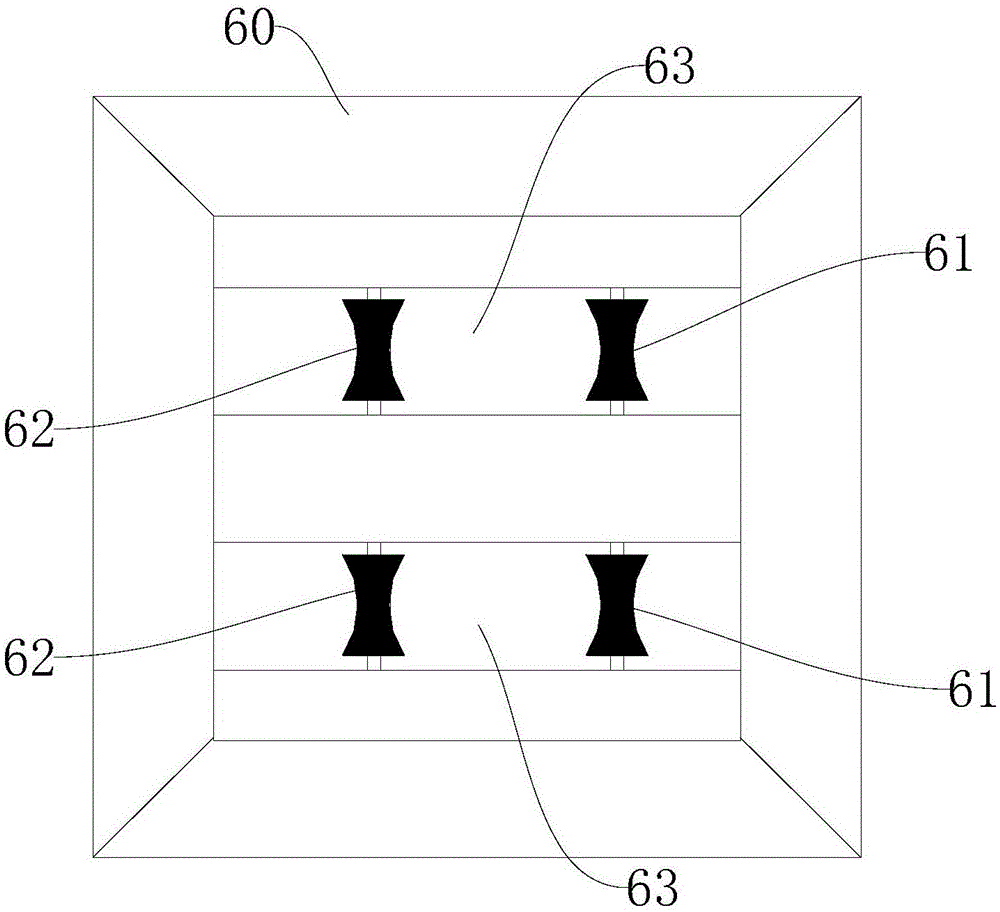

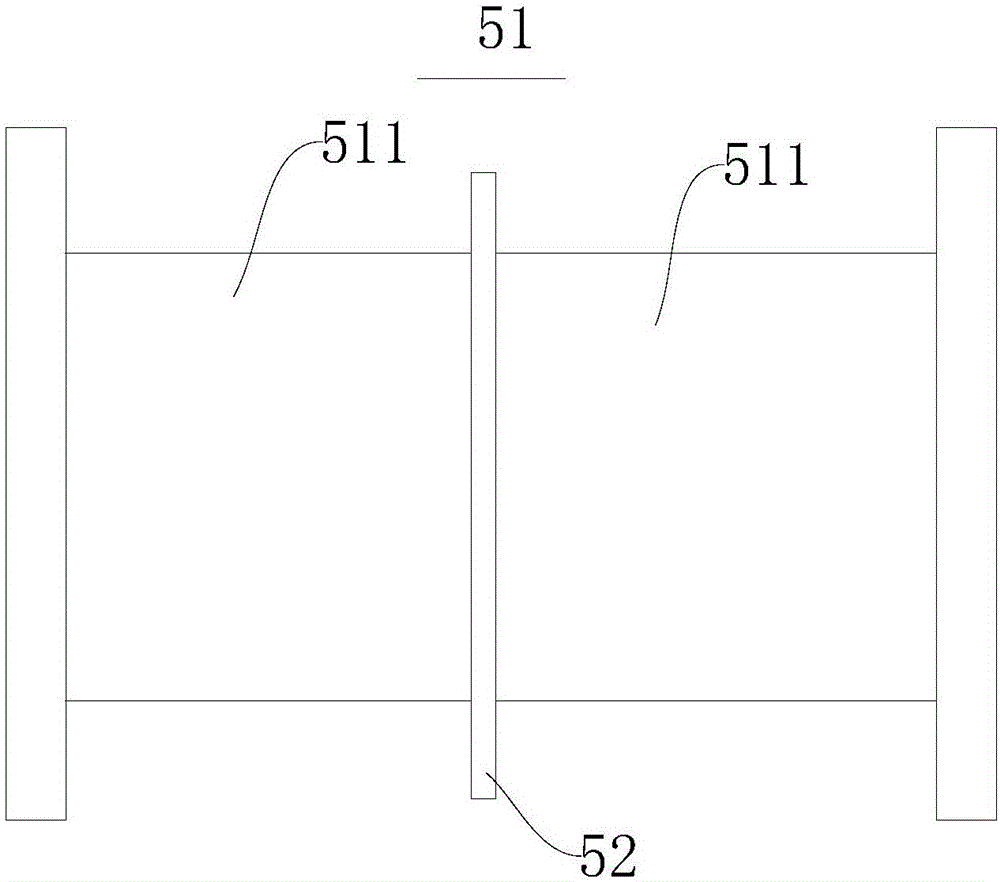

[0030] refer to Figure 1 to Figure 3 As shown, the multi-rope friction hoist 100 according to the embodiment of the present invention may include: a friction wheel 10 , a counterweight 20 , a cage 30 , a hoisting rope 40 , a stabilizer 50 and a guide bracket 60 .

[0031] Specifically, the counterweight 20 is arranged under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com