Drinking machine with zero-pressure hot tank and method for controlling drinking machine

A direct drinking machine and hot pot technology, applied in the field of direct drinking machines, can solve the problems that the hot pot 2 safety hazards cannot be completely eliminated, and achieve the effect of eliminating hidden safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

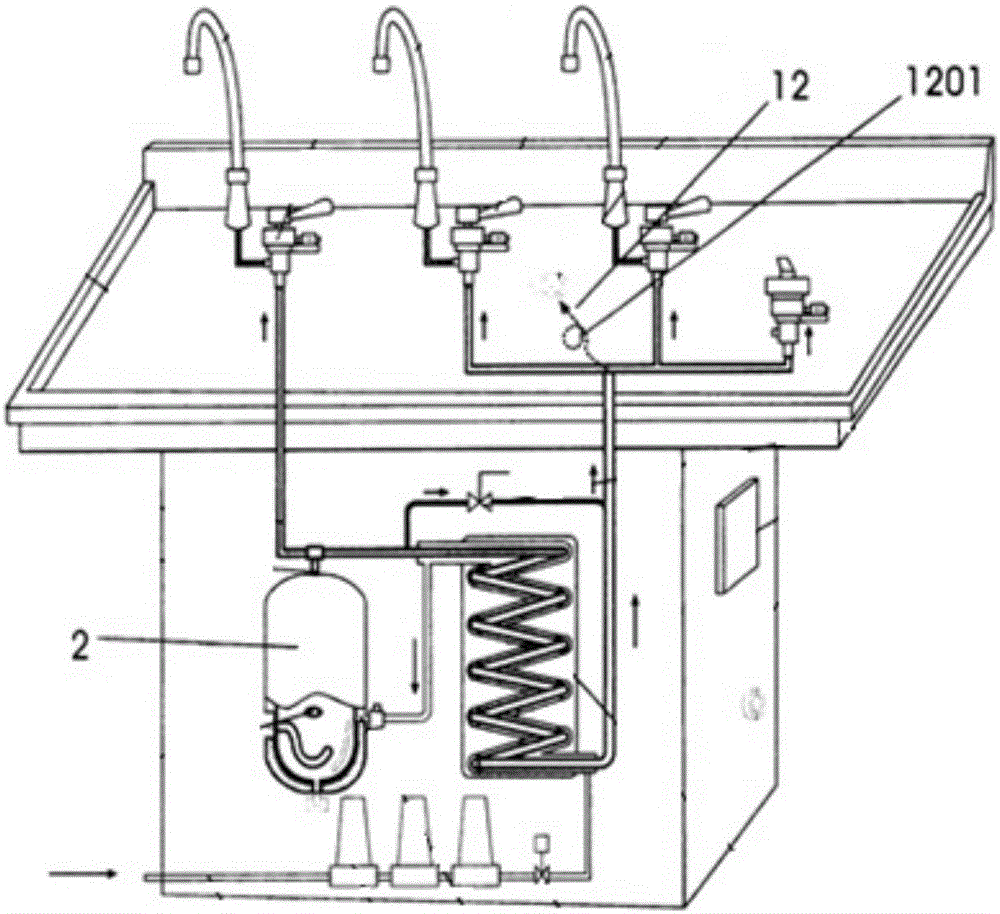

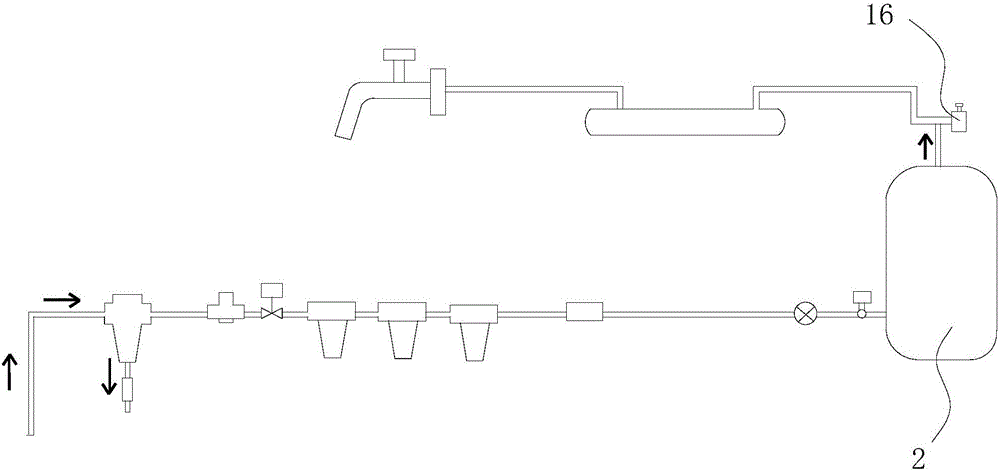

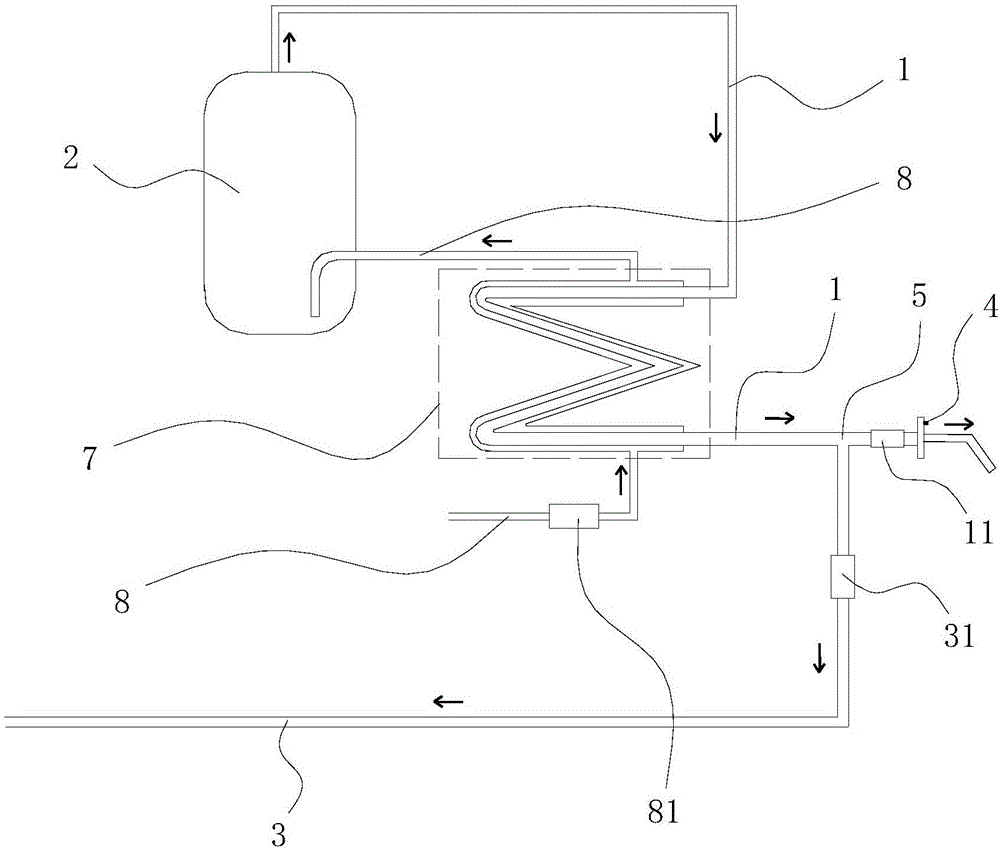

[0029] This preferred embodiment provides a hot pot zero-pressure direct drinking machine. Such as image 3 As shown, the hot tank zero-pressure direct drinking machine includes a water outlet pipe 1, a hot tank 2 and a waste water pipe 3, the water outlet pipe 1 is connected to the water outlet end of the hot tank 2, and the waste water pipe 3 is connected between the inlet and the outlet of the water outlet pipe 1 During this period, a waste water solenoid valve 31 is provided on the waste water pipe 3; when the hot tank 2 is in a heated state and the outlet of the outlet pipe 1 is closed, the heated and expanded water in the hot tank 2 passes through a part of the outlet pipe 1 and then passes through the waste water Tube 3 exits.

[0030] The hot tank 2 of the direct drinking machine is connected to the waste water pipe 3 through a pipeline, and when the hot tank 2 is in a heated state but the outlet of the water outlet pipe 1 is closed, the heated and expanded water is d...

Embodiment 2

[0043] This preferred embodiment provides a hot pot zero-pressure direct drinking machine, the structure of which is basically the same as that of the preferred embodiment 1. The difference is that: if Figure 4 As shown, a three-way valve 6 is provided at the connection 5 between the waste water pipe 3 and the water outlet pipe 1 . When no one is taking water, the three-way valve 6 automatically connects the front section of the outlet pipe 1 with the waste water pipe 3, ensuring that the pressure of the hot tank 2 can be relieved through the waste water pipe 3, and that the hot tank 2 is always in a zero-pressure state; Through valve 6 communicates with the front section of water outlet pipe 1 and the back section automatically, and just can receive water by opening tap switch 4, still guarantees that hot tank 2 is in zero-pressure state now.

[0044] On the basis of the above structure, a check valve 32 can be provided on the waste water pipe 3 to prevent waste water from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com