Glass fiber drawing and bundling control system

A technology of glass fiber yarn and glass fiber, which is applied in the field of new glass fiber drawing cluster control system, can solve problems such as unevenness, broken filament tension, etc., and achieve the effects of ensuring uniformity, reducing broken filaments, and low hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

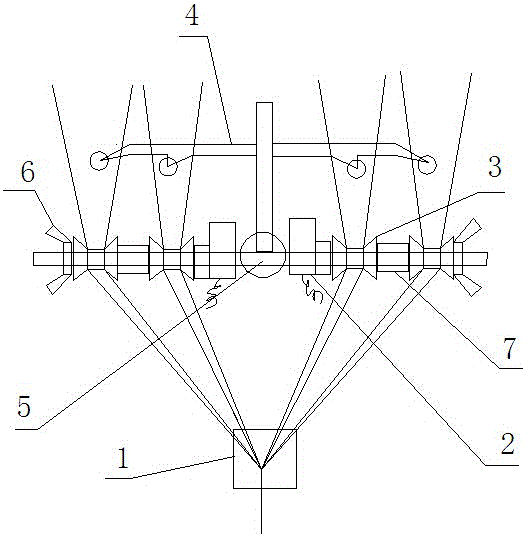

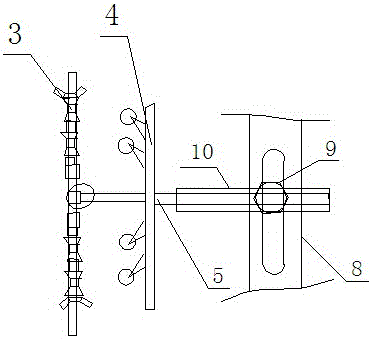

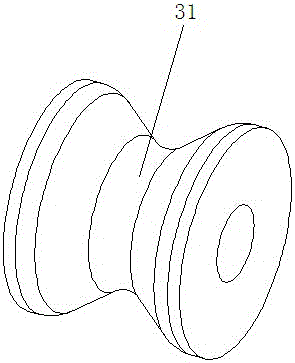

[0020] see figure 1 , the embodiment of the present invention glass fiber drawing cluster control system, including a rotatable multifunctional support 5, a saddle-shaped small cluster wheel 3, a dripping device 4, a rotating motor 2 that provides the rotational power of the small cluster wheel 3, and provides tow partitions Partition controls for control7. The above accessories are uniformly installed on the rotatable multifunctional bracket 5, and the fixing between two or more saddle-shaped small cluster wheels 3 and the rotatable multifunctional bracket 5 is realized by fasteners 6, wherein the saddle type The number of small cluster wheels 3 ranges from 2 to 8. In general, the more commonly used state is 4, that is, there are 4 small cluster wheels 3 in this embodiment, and there are two small cluster wheels on both sides of the multifunctional support 5 3. The small cluster wheels 3 on both sides are each driven by a rotating motor 2, and the interval control is realize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com