Device and method for producing hollowed fancy yarn

A fancy yarn and production device technology, which is applied in yarn, textiles and papermaking, etc., can solve the problems of yarn scrapping and inability to produce hollow-out fancy yarn, etc., and achieve high yield, simple and reliable device, and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

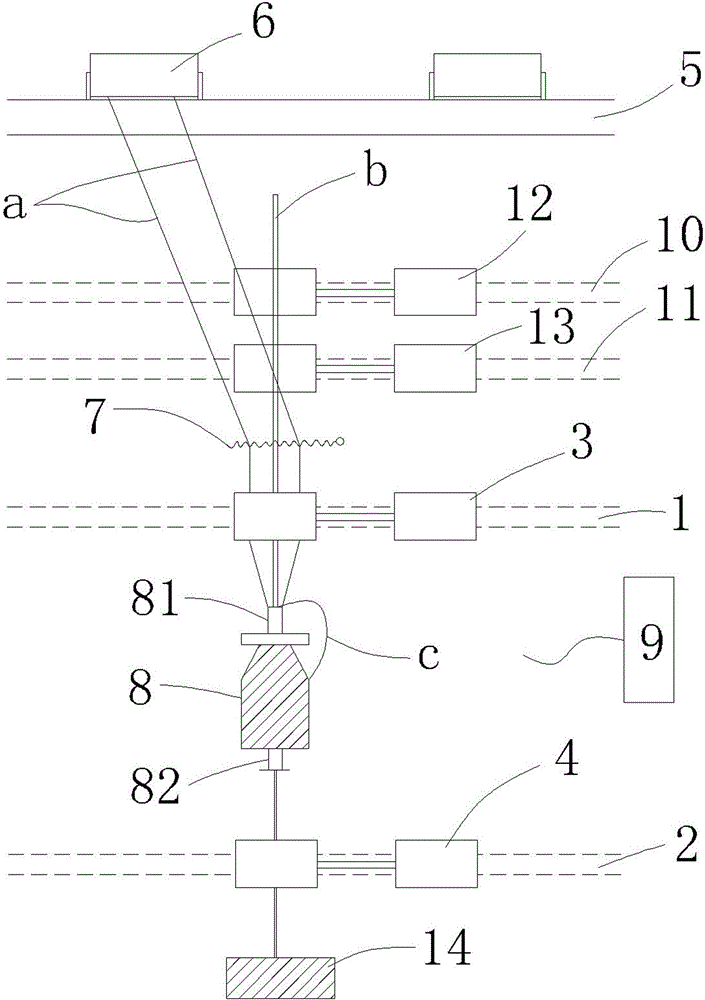

[0031] A hollowed-out fancy yarn production device, including a front roller 1 and an output roller 2 linked to each other, and a front top roller 3 and an output pressure roller 4 respectively installed thereon. This embodiment also includes a core roller 5, and The core wire pressure roller 6 on it is used to control the tension of the core wire a; the spring guide hook 7 is used to limit the operating positions of the two core wires a; the hollow ingot 8 is provided with a pressure line b and provided with There are spindle inlet 81 and spindle outlet 82; the controller 9 is used to control the speed of each group of rollers; the front roller 1 and the front roller 3 on it are used to pull the decorative thread c; two separate cores The thread a is merged at the inlet 81 of the hollow spindle 8 through the spring guide hook 7, and forms a triangular area between the front roller 1 and the hollow spindle 8, and the decorative thread c drawn by the front roller 1 is located on...

Embodiment 2

[0034] Based on the production method of embodiment one, its 13 hollow yarn weaving technology:

[0035] Preliminary preparation, core thread a: two 40D nylon filaments; crimping thread b: one 70D nylon filament; decorative thread c: 100% super cotton sliver, 0.8G / M (gram weight per meter), this embodiment That is roving.

[0036] During the experiment, the method of conventional core wire porcelain mouth was canceled, and the method of merging the core wire a from the conventional right core wire roller 5 through the core wire porcelain mouth on the hollow ingot 8 and the crimping wire b decorative wire c was changed to Core thread roller 5 exits on the left side of the cradle, drafts from front roller 1 and decorative thread c (roving) to the top of hollow spindle 8 and merges with crimping thread b. Since the width of decorative thread c (roving) is generally about 0.5CM, the dispersion of decorative thread c cannot be fully controlled with 70D silk. In the later experimen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap