Installation structure of one-way clutch

一种单向离合器、构造的技术,应用在单向离合器、离合器、联轴器等方向,能够解决动作不良等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

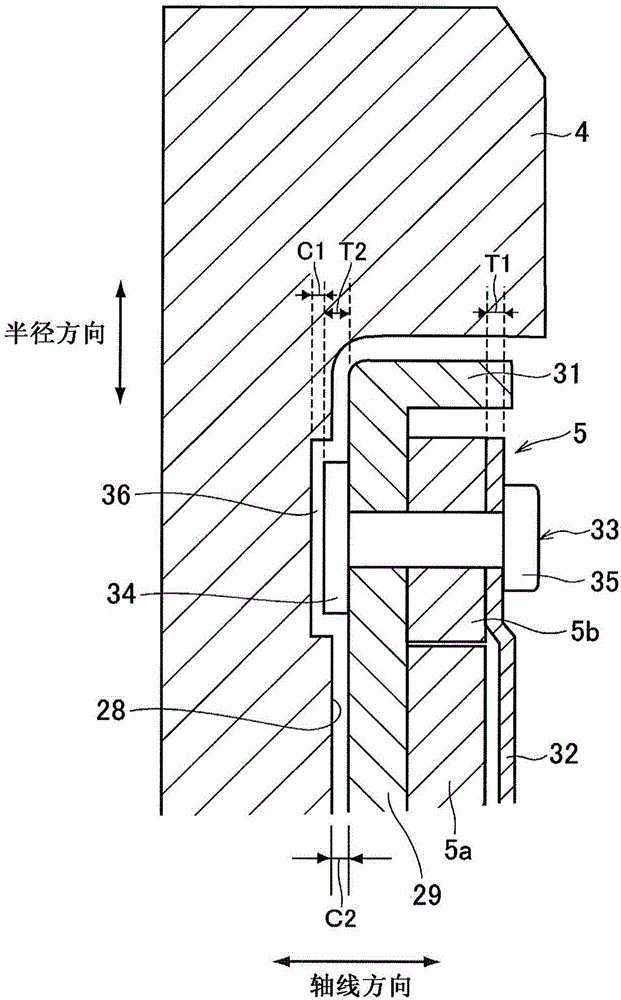

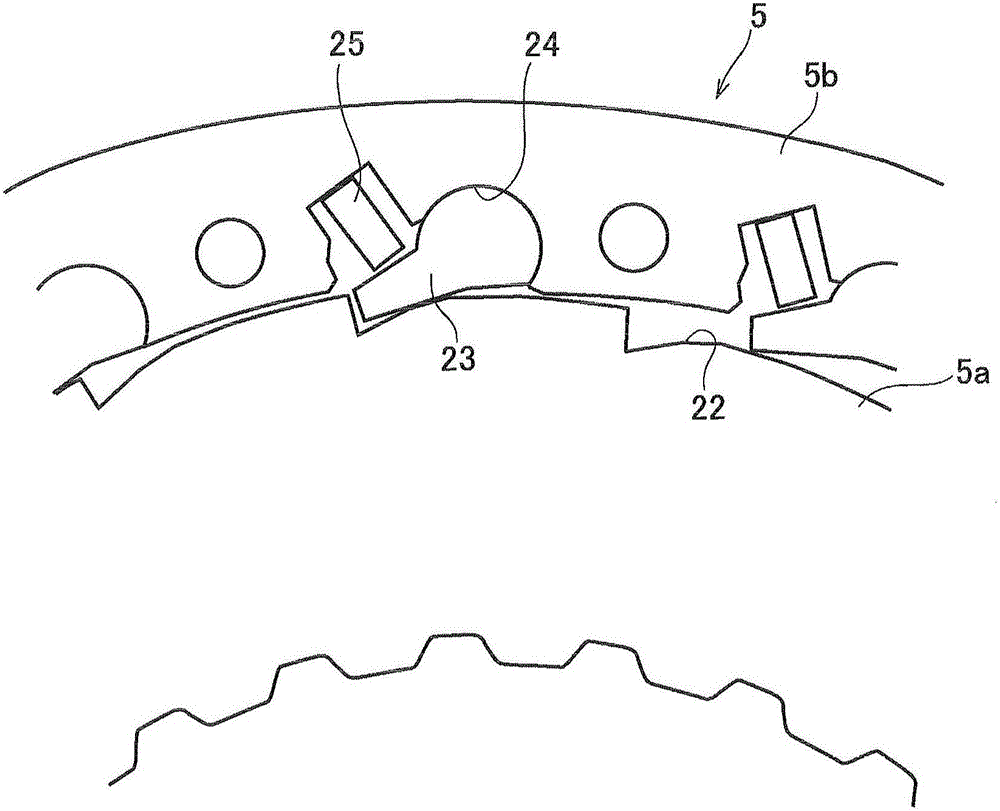

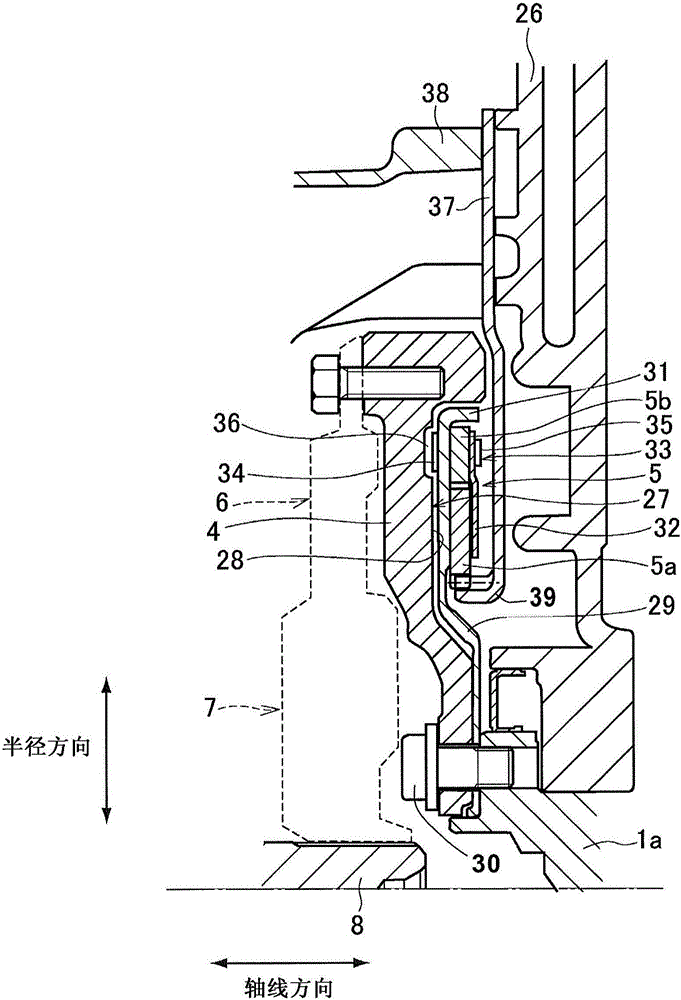

[0029] Image 6 It is a schematic diagram showing an example of a power train equipped with a one-way clutch according to an embodiment of the present invention. The power train shown here includes an engine (ENG) 1 and a first electric motor (MG1) 2 and a second electric motor (MG2) 3 as driving power sources. A flywheel 4 is attached to the output shaft (crankshaft) 1a of the engine 1. A one-way clutch (hereinafter referred to as OWC) 5 that prevents the output shaft 1a from rotating in the negative direction (rotation in the opposite direction to the rotating direction of the engine 1) of the output shaft 1a together with the flywheel 4 is provided. The structure of OWC5 is described later.

[0030] A damper mechanism 7 is connected to the flywheel 4 via a torque limiter 6, and an input shaft 8 is connected to the damper mechanism 7. The torque limiter 6 is a well-known structure in which a plate on the driving side and a plate on the driven side are brought into frictional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com