Dynamic sealing isolation cavity used for rotation component of propellant and explosive dust environment

A technology of rotating parts and dynamic sealing, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of high risk, dust flying, friction effect, etc., to eliminate the possibility of hard friction and good intrinsic safety , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

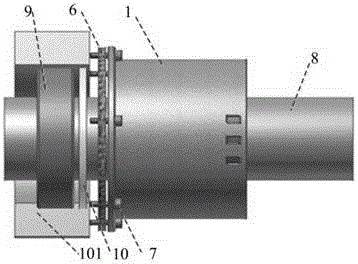

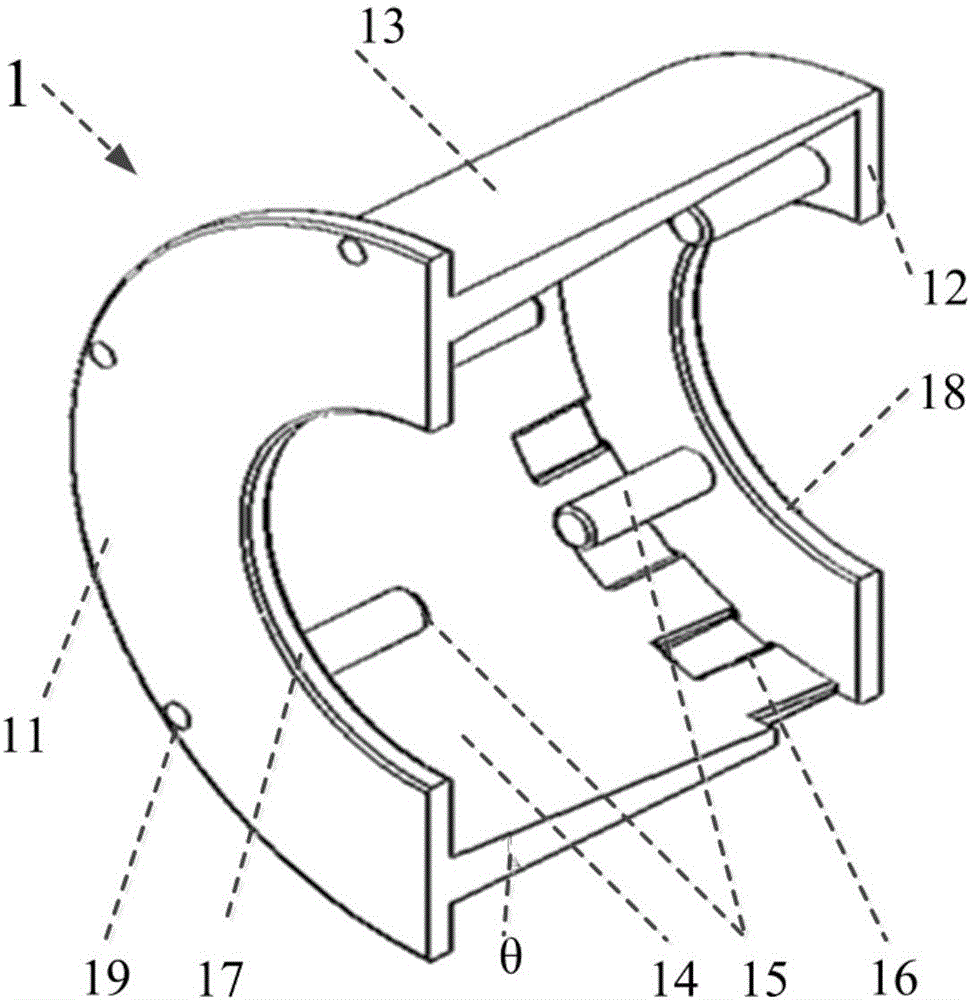

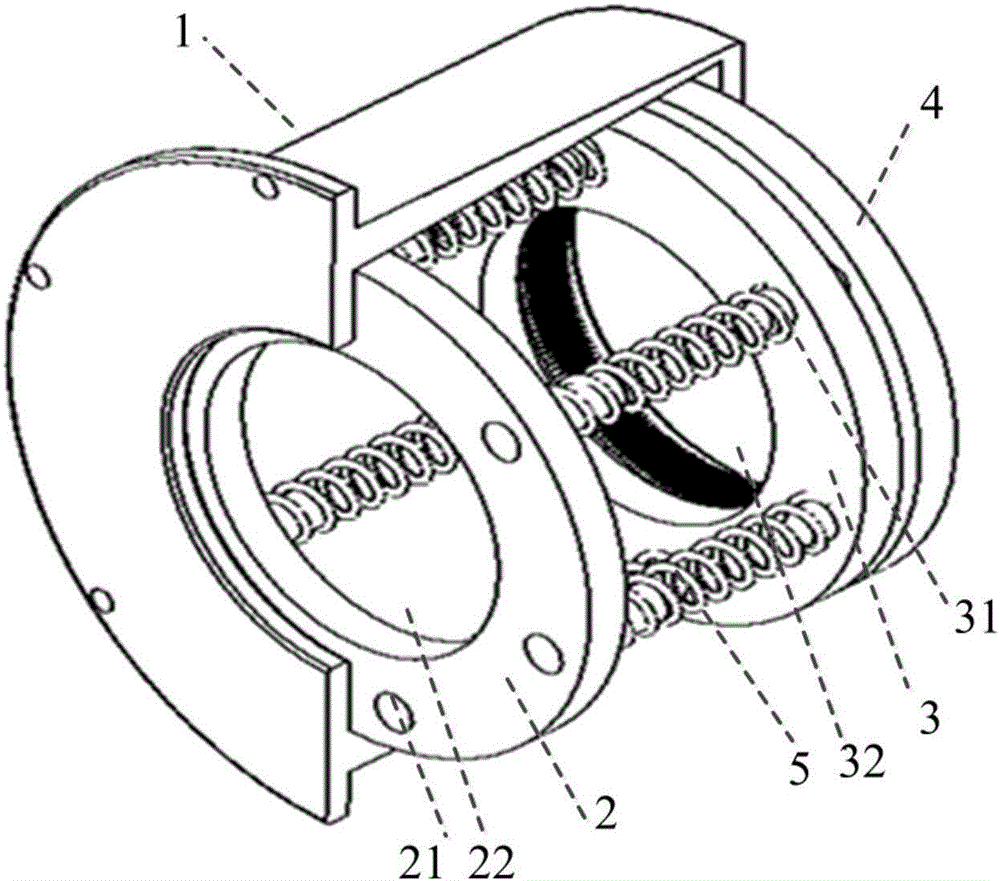

[0023] figure 1 Shown is a schematic diagram of the installation structure of a dynamic sealing isolation chamber for rotating parts in a propellant and explosive dust environment, including an isolation chamber housing 1, conductive gaskets 6, bolts 7, shafts 8, bearings 9, seals 10, and bearing seats 101, wherein the shaft 8, the bearing 9, the seal 10, and the bearing seat 101 are parts of the working equipment in the explosive dust environment, and the shaft 8, the seal 10, and the bearing seat 101 are directly exposed to the explosive dust environment; 1 and its internal components are the entire dynamic sealing isolation cavity, the dynamic sealing isolation cavity is installed on the bearing housing 101 through bolts 7 as a whole, and during installation, a conductive gasket 6 is used between the bearing housing 101 and the dynamic sealing isolation cavity; isol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shaft diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com