Heat exchanger assembly

A technology of heat exchangers and components, applied in the direction of heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of large space occupation, low processing cost, low heat dissipation efficiency, etc., and achieve easy installation and maintenance, Lower heating costs and lower material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

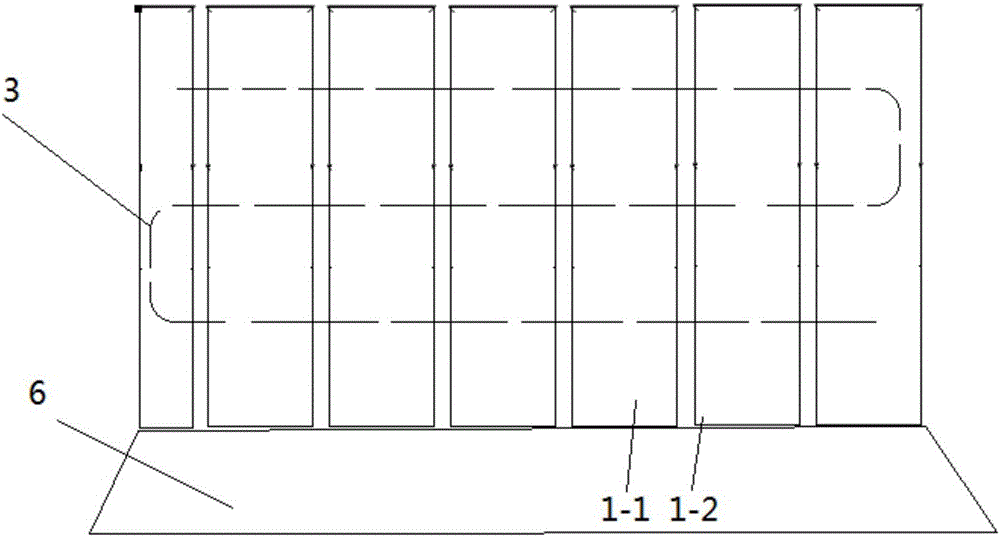

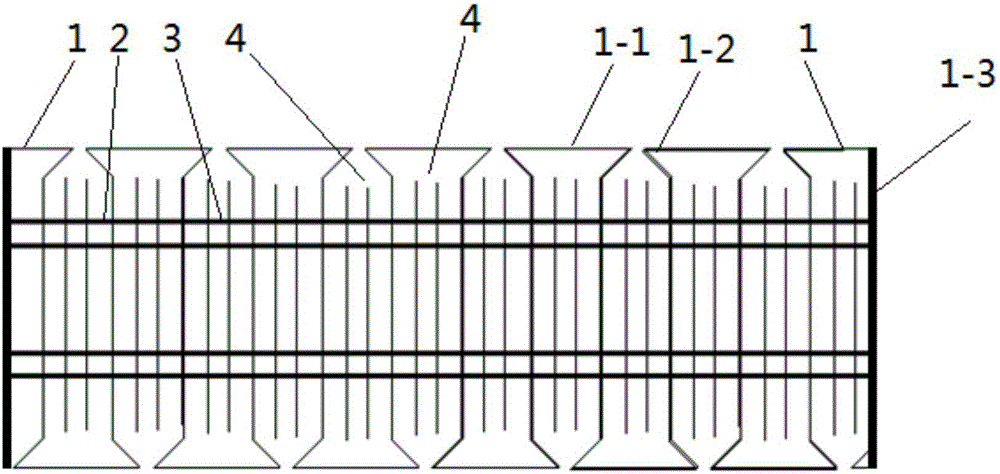

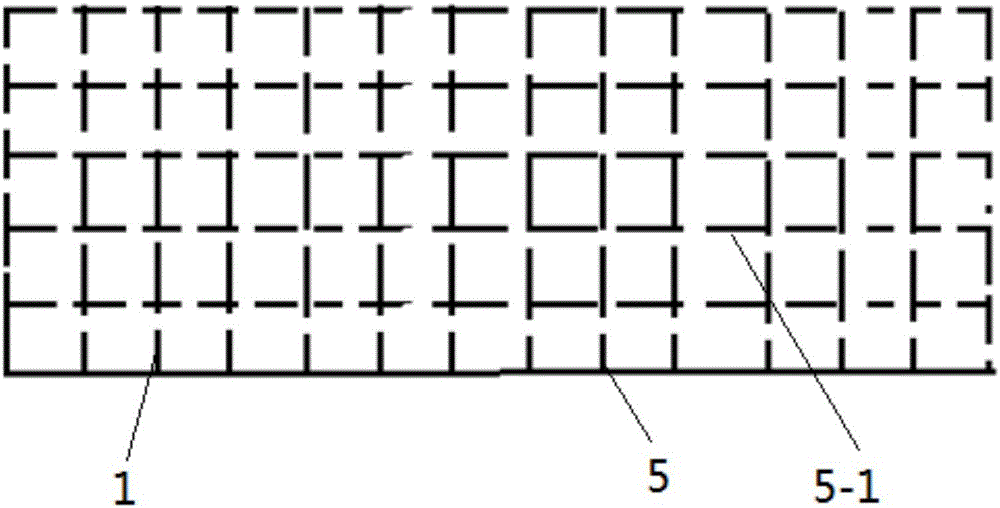

[0033] Example 1 as Figure 1-10 As shown, a heat exchanger assembly includes copper tubes, cooling fins, and contour cooling fins. It is a continuously folded quasi-square wave or triangle, but the corners of the quasi-square wave or triangle are evenly convex when the outer plane of the quasi-square wave is kept horizontal, and the heat dissipation fins are evenly distributed in the contour heat sink; the contour heat sink 1 The thickness is 0.35-1.5mm, and the better thickness is 0.5-1.0mm. At the same time, it is used as the outer plane of the radiator, the cooling fins and the contour cooling fins. There are flat plates (both are aluminum plates), and it is better to form an integrated plate with a profile heat sink. 1-2 is the cross-section of the profile heat sink, which is a continuous folded quasi-square wave or triangle, quasi-square wave or triangular corner protruding 20-75 degrees (formed by straight line angle, trapezoidal angle or arc line) angle Structure (a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com