Method for determining test conditions of rotation fatigue of automobile chain

A fatigue test and determination method technology, applied in the field of chain transmission, can solve the problems of long test period, chain fatigue strength distortion, etc., and achieve the effect of shortening the time of exploration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method for testing the rotational fatigue performance provided by the present invention will be described in detail below in conjunction with an implementation case.

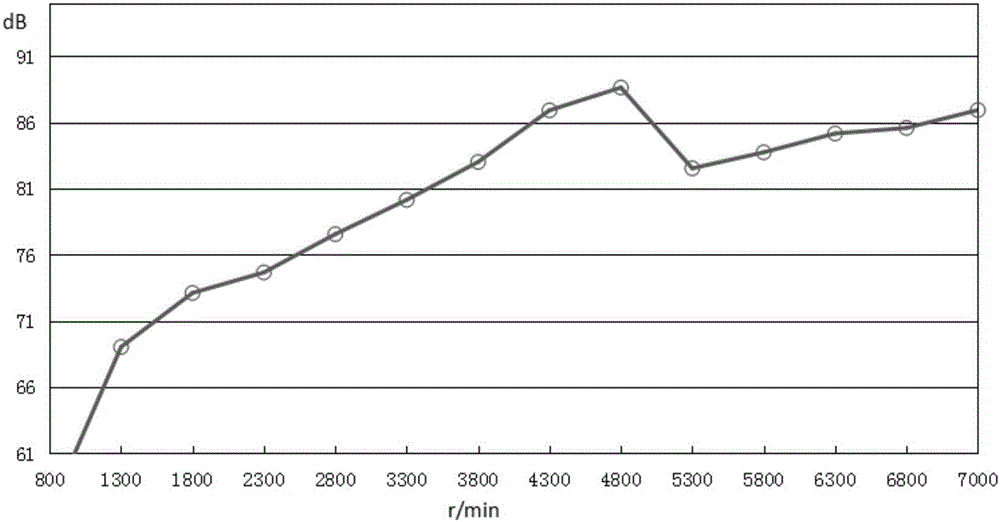

[0027] The idle speed of the engine is 800r / min, and the maximum speed is 7000r / min. After the noise test, the test speed of the chain is determined to be 800r / min, 1300r / min, 1800r / min, 2300r / min, 2800r / min, 3300r / min, 3800r / min , 4300r / min, 4800r / min, 5300r / min, 5800r / min, 6300r / min, 6800r / min, 7000r / min, the actual noise value under the load of 1.960kN (eg figure 1 ). The noise is the largest at 4800r / min, which is used as the rotation speed for the rotary fatigue test.

[0028] The tensile strength of the chain is determined to be Q=14.7kN through a tensile test, and the load step is determined to be 1.5%Q.

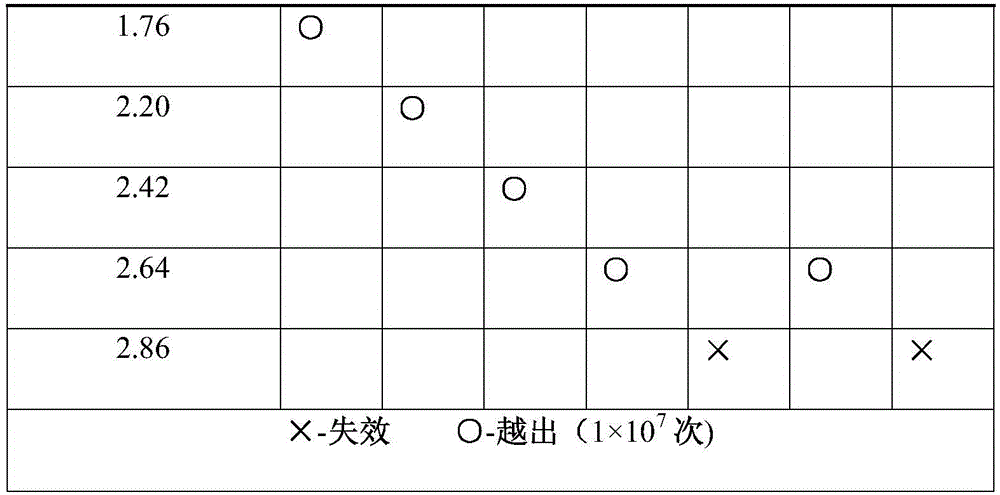

[0029] According to the present invention, the test loads are respectively 1.76kN, 2.20kN, 2.42kN, 2.64kN, 2.86kN...

[0030] The test results are shown in Table 1.

[0031] Table 1 Resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com