Power battery tab adhesive encapsulation device and adhesive encapsulation method thereof

A technology of power battery and rubber wrapping device, which is applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of unsatisfactory quality and appearance of the finished battery, insufficient flatness of the glue wrap, and easy-to-open glue of the tape, so as to avoid battery extremes. The effects of ear short circuit, flexible device and firm tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

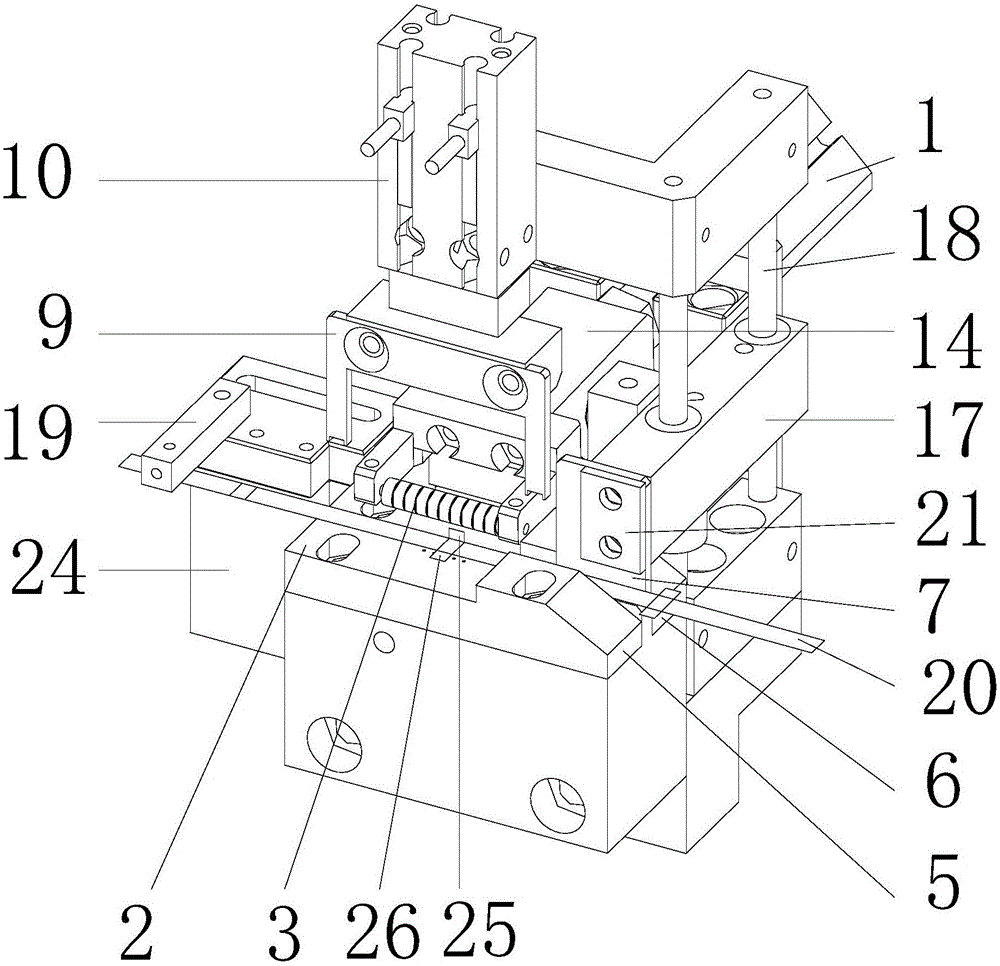

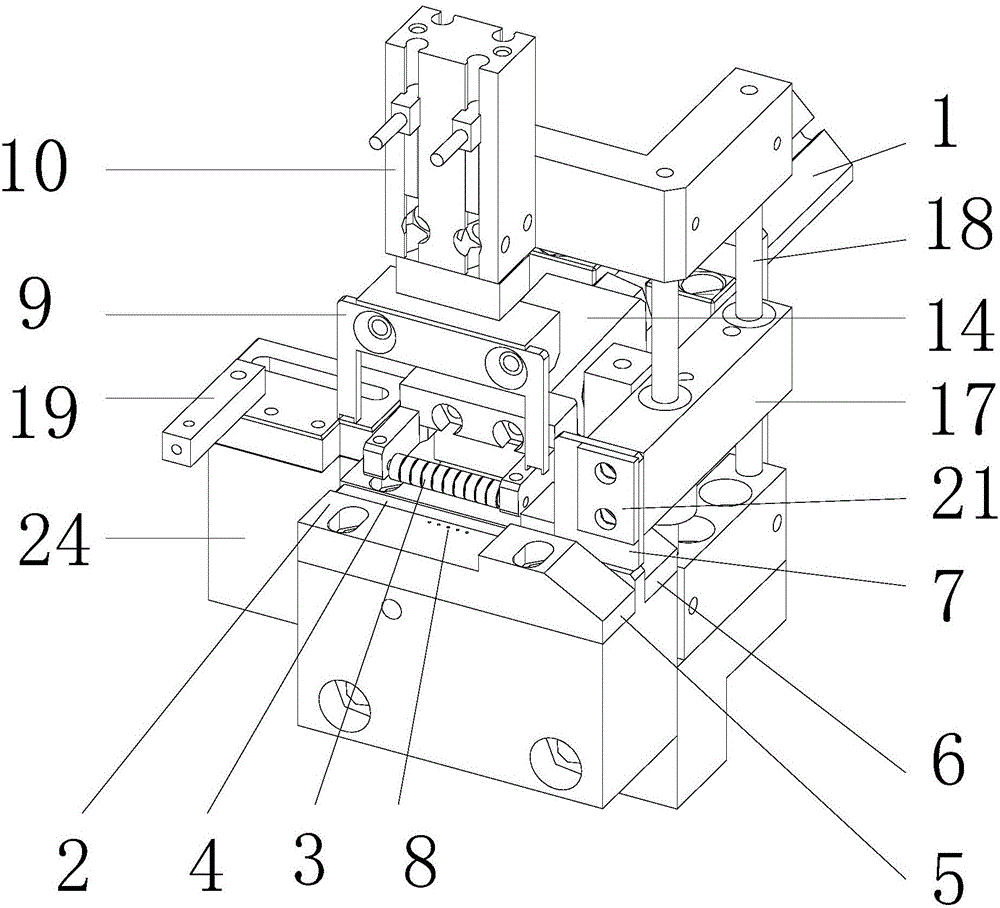

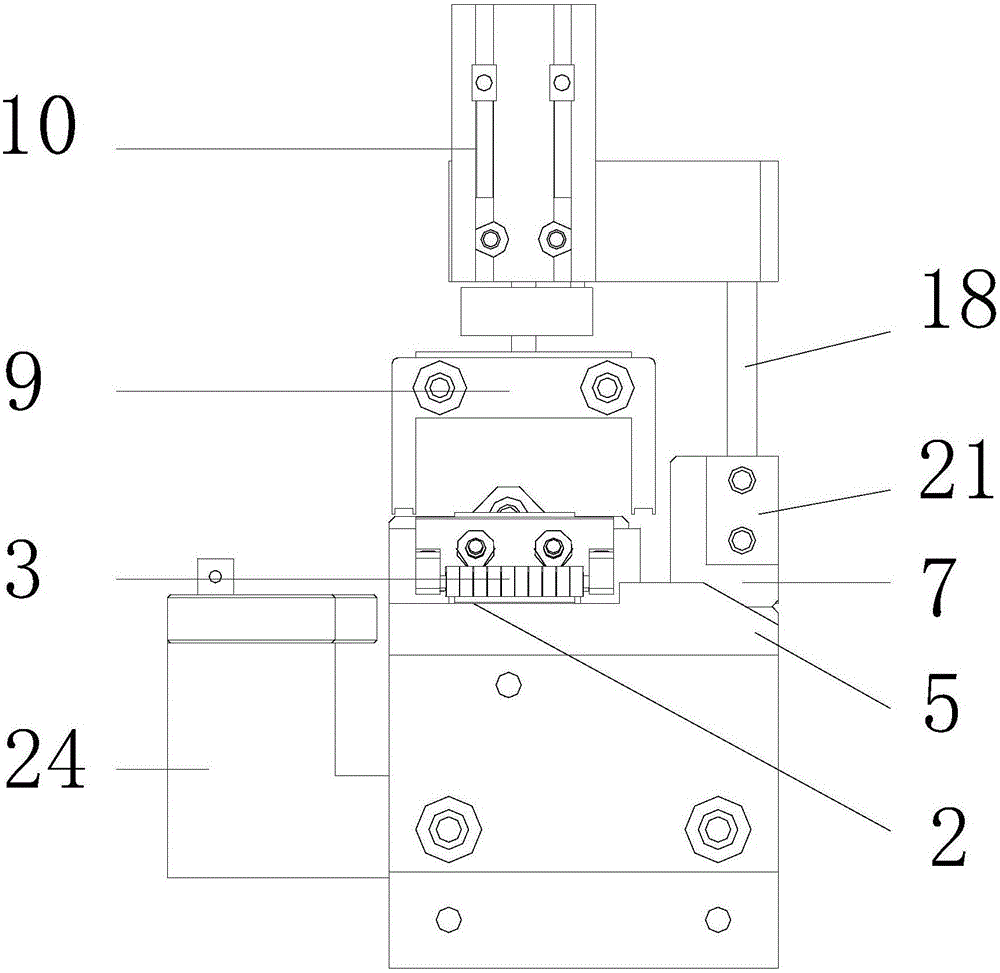

[0028] A power battery lug wrapping device, including a wrapping driver 1, a guide table 2, a pressure head 3, a channel 4, a front limit block 5, a rear limit block 6, a baffle plate 7, an air blowing hole 8, a positioning Fork 9, press cylinder 10, slide rail 11, slide block 12, briquetting base plate 13, briquetting 14, elastic member 15, top block 16, baffle plate adjustment block 17, guide rod 18, pressing plate 19, fixed plate 21, Pressure head support 22, cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com