Heat dissipation device for directly pressing power components by utilizing shell

A technology of power components and heat sinks, applied in the field of heat sinks of power components, can solve the problems affecting the service life of power heating components and controllers in controllers, low heat transfer efficiency of power heating components, and large temperature difference of metal heat sinks on heat dissipation surfaces. and other problems to achieve the effect of changing the installation method, fully conducting heat and heat dissipation, and improving the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

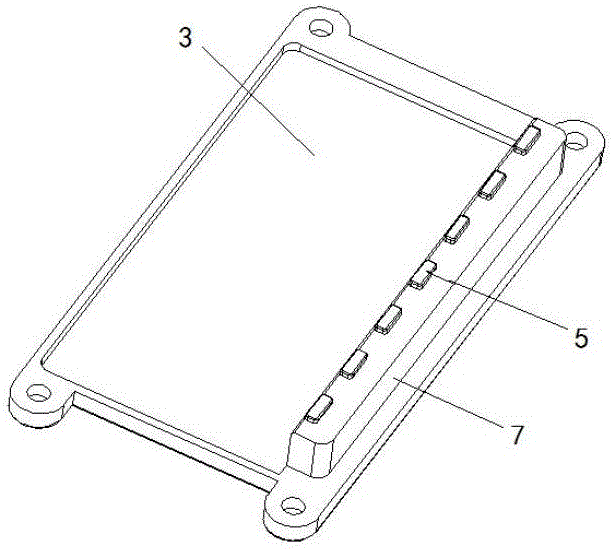

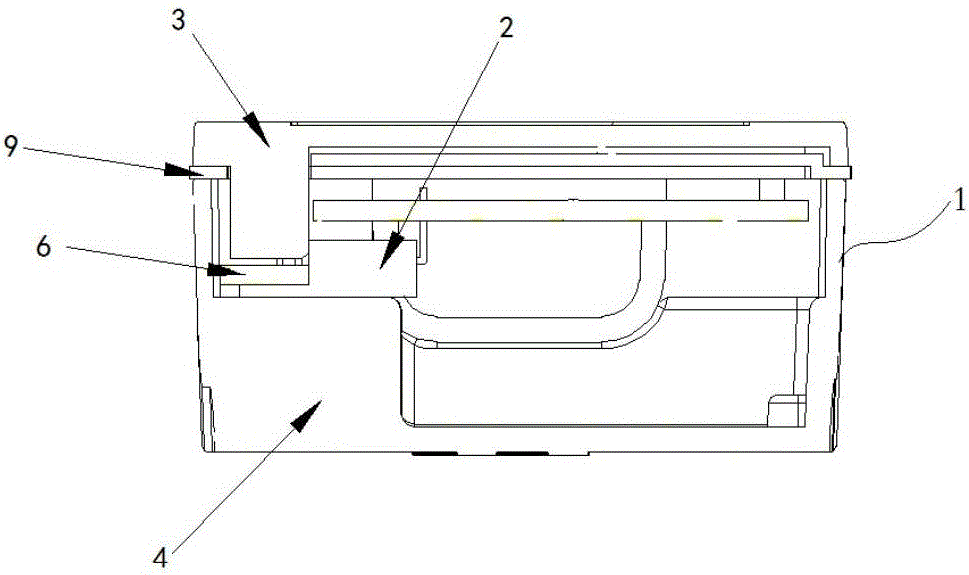

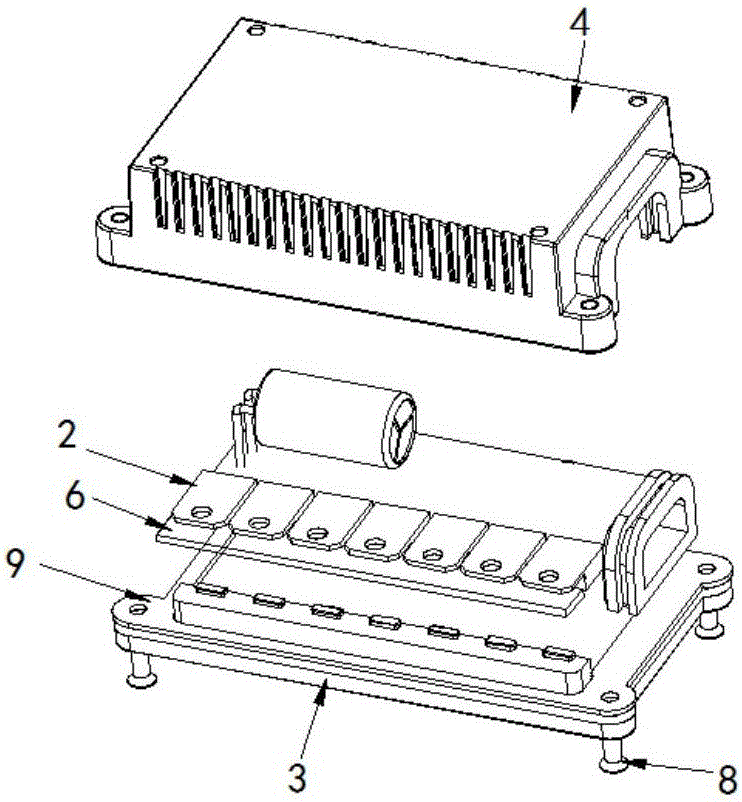

[0012] Such as figure 1 with 2 As shown, the heat dissipation device of the present invention, which utilizes the shell to directly press the power element, includes a shell 1 and several power elements 2, and the shell is made of die-cast aluminum. The casing 1 is composed of an upper casing 3 and a lower casing 4 , and several protrusions 5 are arranged on the upper casing 3 or the lower casing 4 . The following description will be made by taking the example of disposing the protrusion 5 on the upper casing 3 .

[0013] A plurality of protrusions 5 are designed on the upper case 3 corresponding to the positions where the power components 2 are assembled, or steps 7 are provided on the upper case 3 at positions corresponding to the power components 2 to be assembled, and then several protrusions 5 are provided on the steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com