Aroma increasing eucommia ulmoides teabag and preparation method thereof

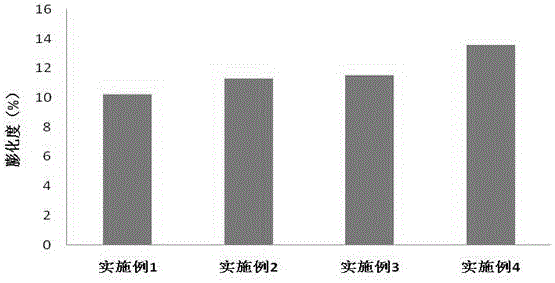

A technology for making tea bags and Eucommia leaves, which is applied to the field of aroma-enhancing Eucommia ulmoides tea bags and its preparation, can solve the problems of unfavorable aroma emission, inconspicuous aroma-enhancing effect, few types, etc., and achieves good reaction aroma-enhancing effect and variety of aromas. The effect of plumpness and good puffing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation method step of the fragrance-increasing eucommia teabag of the present embodiment is as follows:

[0019] (1) Mix 30 g of eucommia leaves, 10 g of Eucommia male flowers, 5 g of Lagerstroemia indica leaves, 20 g of malt, 10 g of germinated brown rice, 5 g of Chinese wolfberry, and 5 g of American ginseng, dry at 120°C for 60 minutes, and then crush to 40 to obtain a mixture;

[0020] (2) Add 20 g of glucose and 0.5 g of ethyl maltol to the mixture obtained in step (1). After mixing evenly, add water to adjust the moisture content to 10%. When the screw speed is 200 r / min and the extrusion temperature is Extrude at 150°C for Maillard reaction to increase aroma, then dry at 100°C to a moisture content of 8%, and then crush to 20 meshes;

[0021] (3) According to the packaging specifications, use non-woven bags for inner packaging, and carton or iron box for outer packaging to obtain the aroma-enhancing Eucommia teabag.

Embodiment 2

[0023] The preparation method step of the fragrance-increasing eucommia teabag of the present embodiment is as follows:

[0024] (1) Mix 30 g of eucommia leaves, 10 g of Eucommia male flowers, 5 g of Lagerstroemia indica leaves, 20 g of malt, 10 g of germinated brown rice, 5 g of Chinese wolfberry, and 5 g of American ginseng, dry at 120°C for 60 minutes, and then crush to 40 to obtain a mixture;

[0025] (2) Add 20 g of fructose and 0.5 g of ethyl maltol to the mixture obtained in step (1). After mixing evenly, add water to adjust the moisture content to 10%, and put it into a twin-screw extruder at a screw speed of 200 r / min, extruding temperature of 150°C for Maillard reaction to enhance aroma, after extrusion, dry at 100°C until the moisture content is 8%, and then pulverize to 20 mesh;

[0026] (3) According to the packaging specifications, use non-woven bags for inner packaging, and carton or iron box for outer packaging to obtain the aroma-enhancing Eucommia teabag.

Embodiment 3

[0028] The preparation method step of the fragrance-increasing eucommia teabag of the present embodiment is as follows:

[0029] (1) Mix 30 g of eucommia leaves, 10 g of Eucommia male flowers, 5 g of Lagerstroemia indica leaves, 20 g of malt, 10 g of germinated brown rice, 5 g of Chinese wolfberry, and 5 g of American ginseng, dry at 120°C for 60 minutes, and then crush to 40 to obtain a mixture;

[0030] (2) Add 20 g of fructose and 0.5 g of ethyl maltol to the mixture obtained in step (1). After mixing evenly, add water to adjust the moisture content to 20%. Put it into a twin-screw extruder at a screw speed of 200 r / min, extruding temperature of 150°C for Maillard reaction to enhance aroma, after extrusion, dry at 100°C until the moisture content is 8%, and then pulverize to 20 mesh;

[0031] (3) According to the packaging specifications, use non-woven bags for inner packaging, and carton or iron box for outer packaging to obtain the aroma-enhancing Eucommia teabag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com