Standable kettle with handle

A technology of a kettle and a handle, which is applied to water-boiling appliances and other directions, can solve the problems of not easy to quickly dissipate, affect the appearance, and occupy a large space for the kettle, and achieve the effect of reducing the heat absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

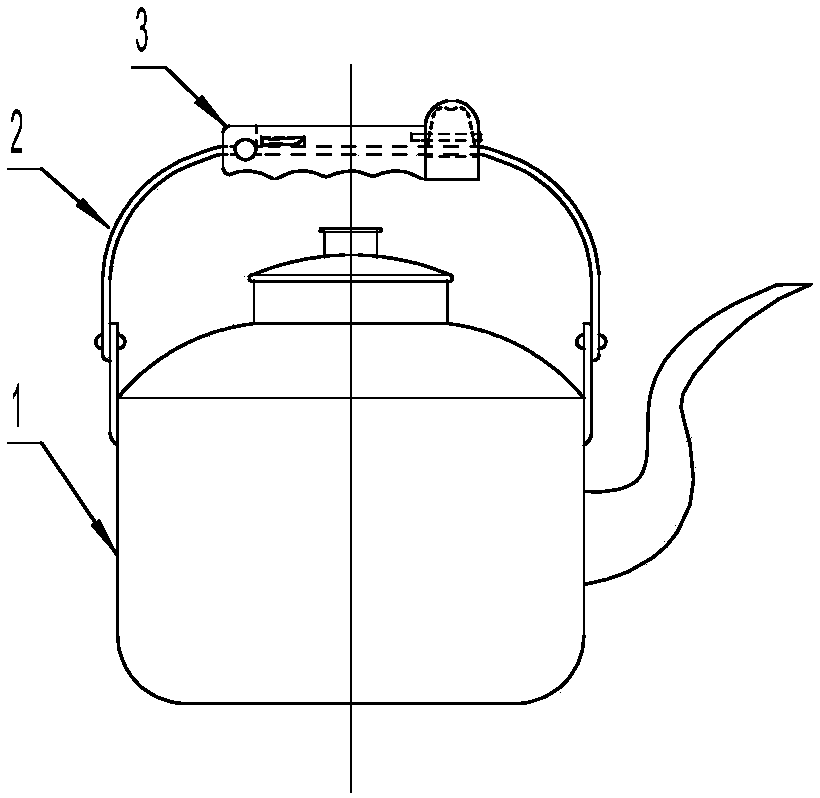

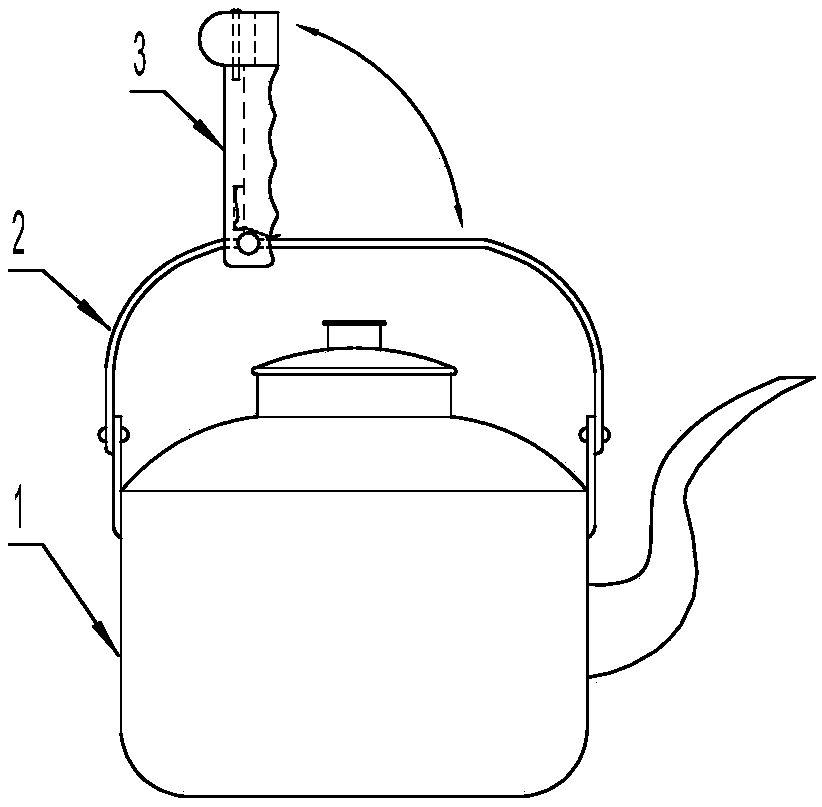

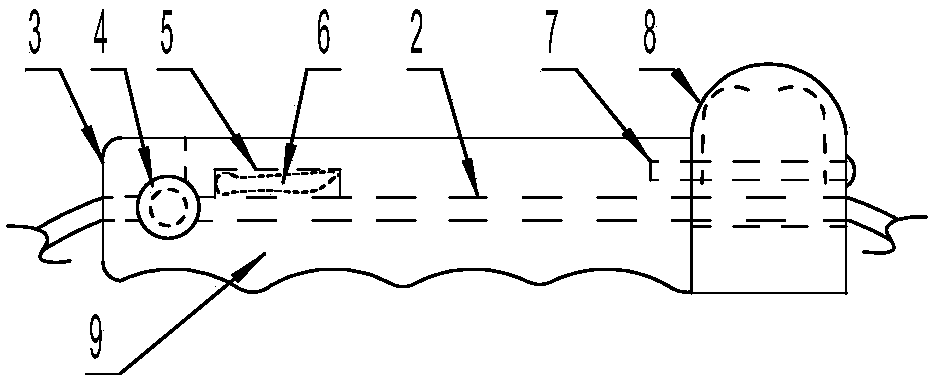

[0013] Below in conjunction with accompanying drawing, this design is illustrated.

[0014] Such as figure 1 , figure 2 ,Such as image 3 , Figure 4 As shown, the kettle of this design includes a kettle body 1, a kettle system 2, and a handle 3, and the kettle system 2 is horizontally fixed to a cylindrical sleeve shaft 4 on the left side of the position where the handle is installed in the middle section; The grip 3 is centered on its downward facing side with a long longitudinally running through the grip and can accommodate the grip groove 9 of the kettle system. The left end section of the grip 9 extends vertically upwards to the top of the grip 3, as Figure 4 As shown, a hole that can penetrate the sleeve shaft 4 is arranged laterally at the corner of the sleeve groove 9 and is movably connected together through the sleeve shaft, so that the sleeve 3 can be opened and closed at an angle of 90 degrees around the sleeve shaft 4, as figure 2 As shown, at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com