Mechanism for traversing elastic waistline

A technology of elastic waist and frame, applied in medical science, clothing, underwear, etc., can solve the problems of difficult to realize high-speed operation of the production line, reduce the service life of equipment, reduce production efficiency, etc., achieve simple structure, improve quality, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

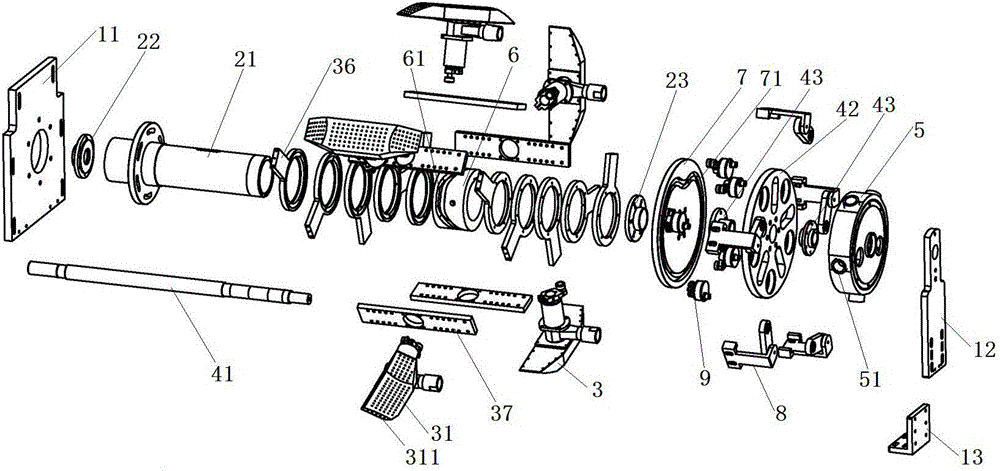

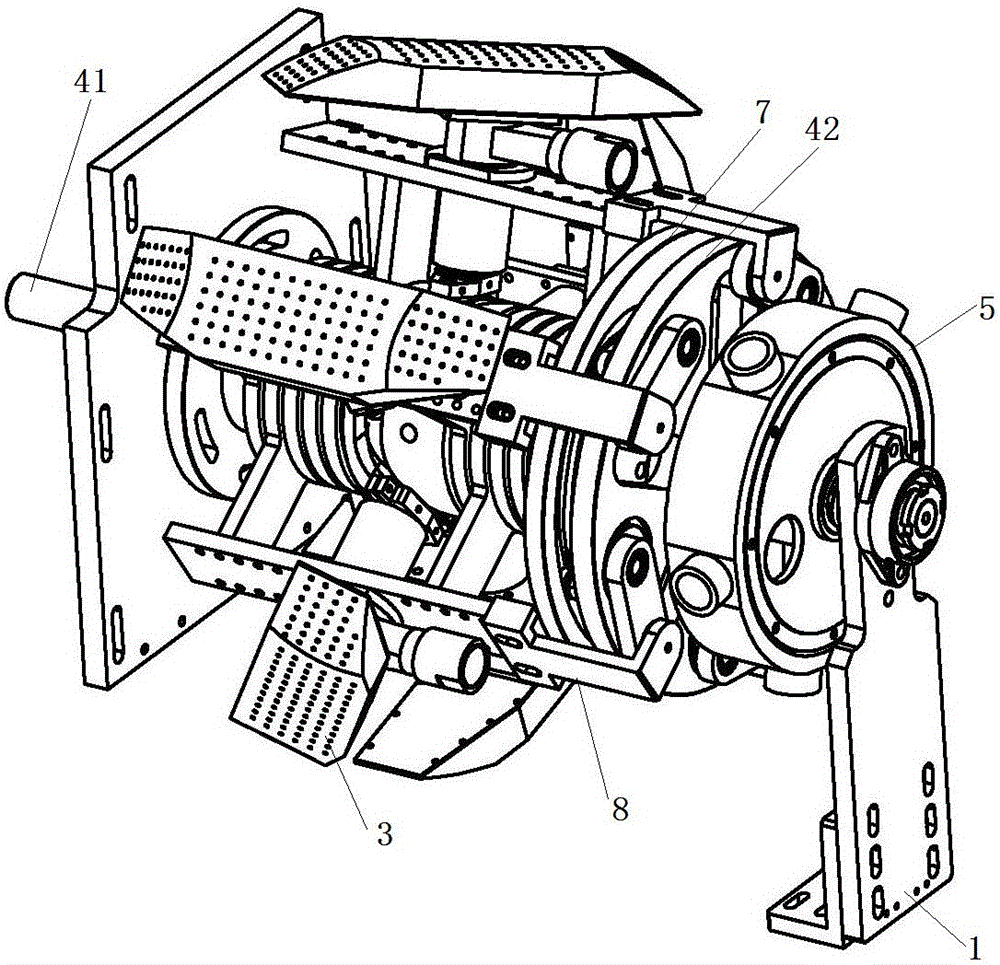

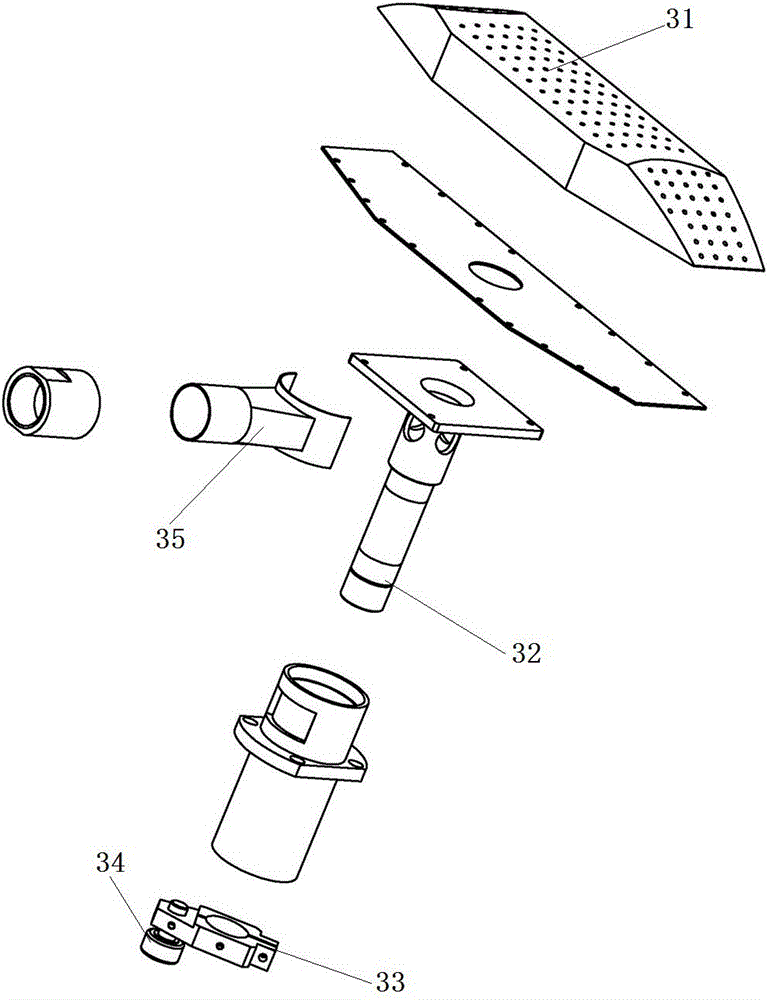

[0021] Such as Figure 1-2 As shown, the elastic waist variable transverse mechanism includes a frame 1, a large bearing seat 21, a drive shaft 41, a drive disc 42, an air distribution chamber 5, a sheave 6, a groove disc 7, and several adsorption devices 3, connecting rods 8 and Eccentric wheel assembly 9.

[0022] The frame 1 includes a front fixing plate 11 , a rear fixing plate 12 and a base 13 fixed on the rear fixing plate 12 . The large bearing seat 21 is framed between the front end fixed plate 11 and the rear end fixed plate 12, and the driving shaft 41 is rotatably sleeved in the large bearing seat 21 through the front end bearing seat 22 and the rear end bearing seat 23, and the two ends of the driving shaft 41 are respectively Both extend out of the large bearing seat 41, one end of which is connected to the drive motor (not shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com