Method for automatically purifying and recycling water discharged from dry quenching water seal system

An automatic purification and CDQ technology, applied in chemical instruments and methods, separation methods, coke ovens, etc., can solve the problems of not involving recycling methods, waste of water resources, and water not being recycled, and achieve energy saving and emission reduction Good effect, water saving and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

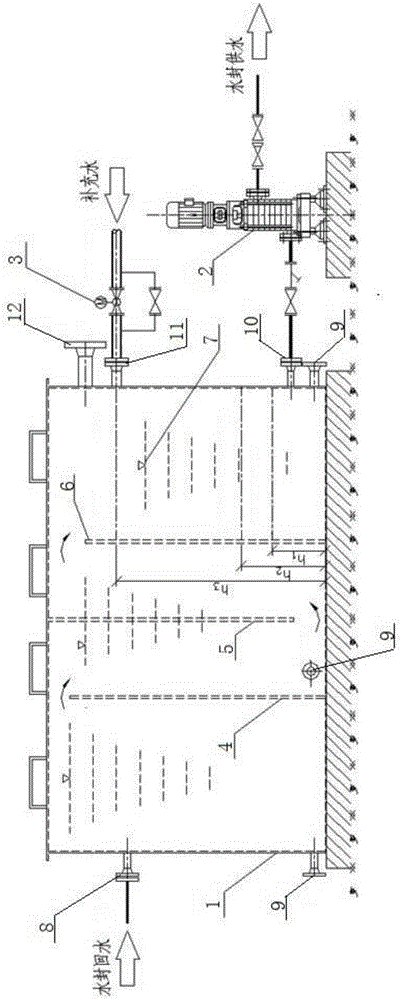

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0025] Such as figure 1 As shown, the automatic purification and recycling method of the CDQ water sealing system drainage in the present invention collects the drainage water of the CDQ water sealing system and sends it into the purified water tank. Send it back to the CDQ water seal system for recycling; the process of automatically purifying the water drain of the CDQ water seal system in the purified water tank includes the following steps:

[0026] 1) The purified water tank includes a water tank 1, a booster pump 2, an electric water supply valve 3 and a water tank level gauge 7. The top of the water tank 1 is closed, and the water tank 1 is provided with a water inlet pipe 8 on one side and an outlet pipe 10 on the other side; the inside of the water tank 1 is composed of The tank partition plate 1, the baffle plate 5 and the tank partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com