A wheel rim ring rolling forming equipment and method

A forming method and forming equipment technology, applied in the direction of metal rolling, etc., can solve the problems affecting the center of gravity of the rim, complex mold design, high forming pressure, etc., and achieve the effect of saving materials, low cost and good forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

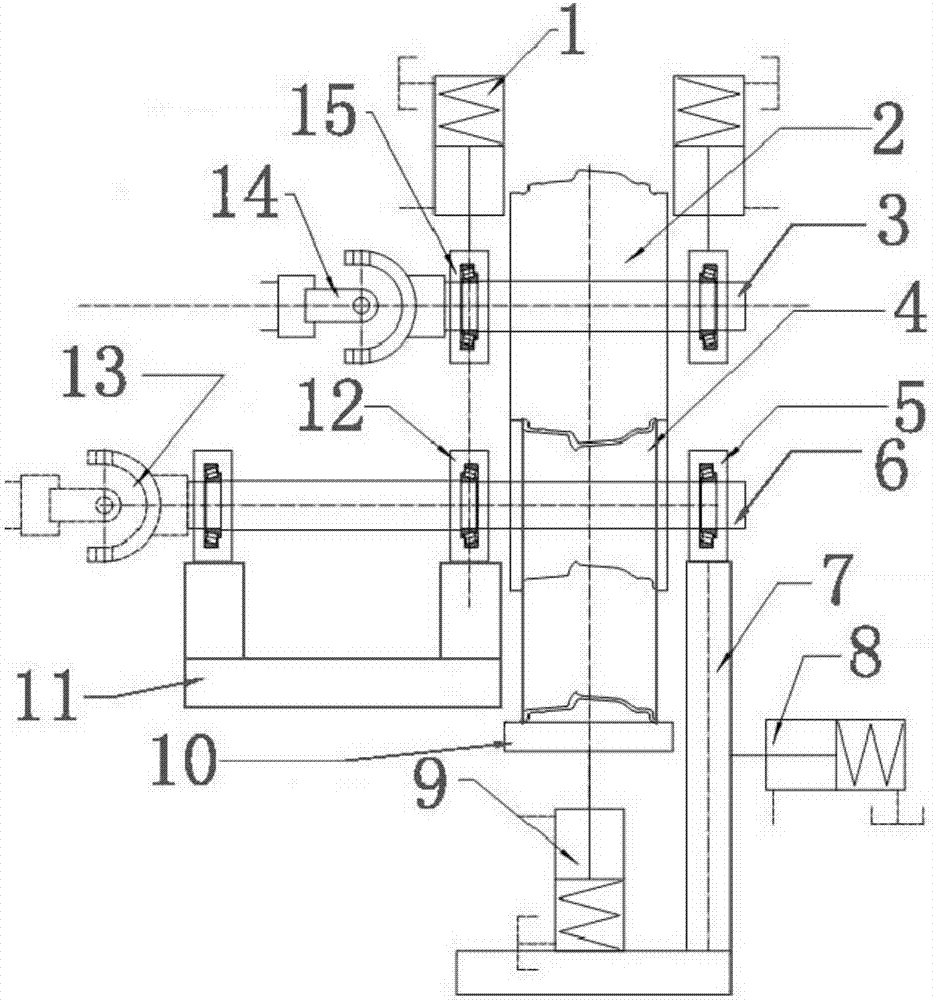

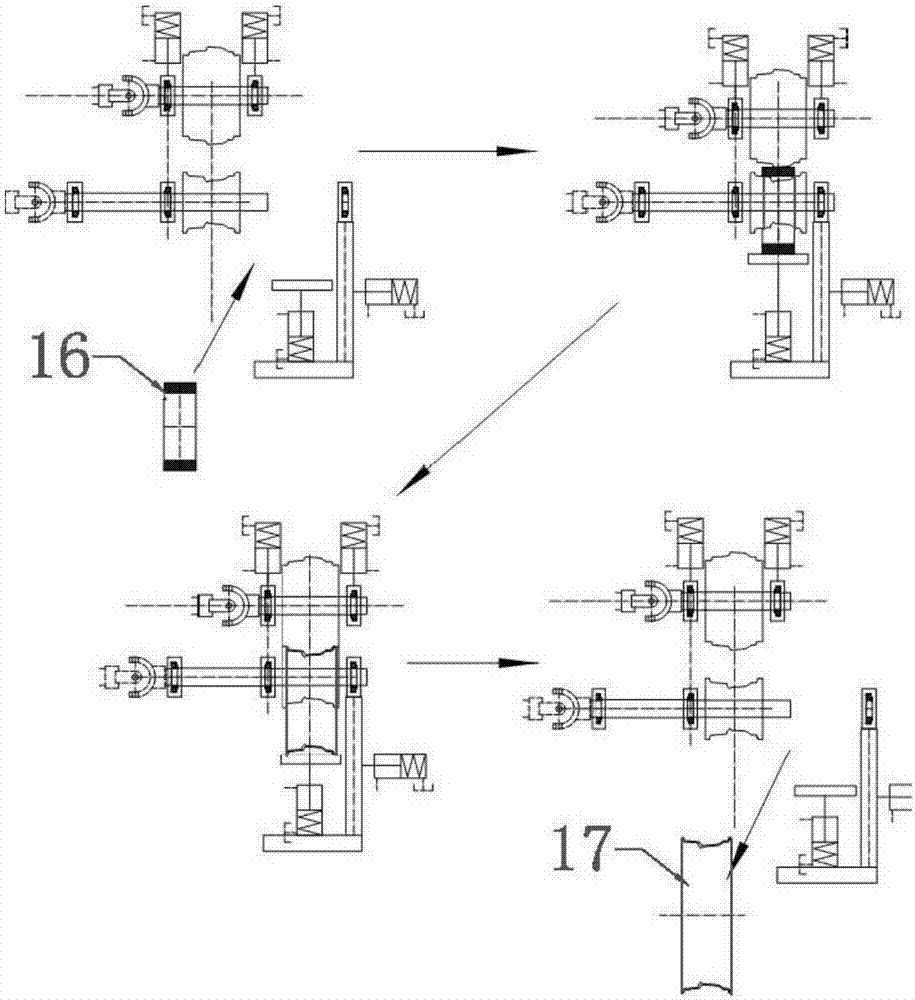

[0029] This embodiment provides a wheel rim ring rolling forming equipment, including a frame, an upper forming roll 2, a lower forming roll 4, a first power system that provides power for the upper forming roll 2, and provides power for the lower forming roll 4 The second power system and the fixed support 11 of the lower forming roller shaft and the movable support 7 of the lower forming roller shaft;

[0030] The upper part of the frame is provided with two first hydraulic cylinders for controlling the lifting of the upper forming roller 2, and each of the first hydraulic cylinders is provided with a connecting rod; the first power system includes an upper forming roller shaft , each of the connecting rods is connected with a first bearing seat 15, and each of the first bearing seats 15 is provided with a first bearing, and the upper forming roller shaft runs through two of the first bearings, and the two of the first bearings The upper forming roller 2 is sheathed on the u...

Embodiment 2

[0036] This embodiment is an improved embodiment based on the first embodiment. In the rim ring rolling forming equipment, the first power system includes a first motor, and the output shaft of the first motor passes through the first universal The joint 14 is connected with the upper forming roller shaft; the second power system includes a second motor, and the output shaft of the second motor is connected with the lower forming roller shaft through the second universal joint 13, because the rim When the ring rolling forming equipment is working, it will rotate rapidly, and both the upper forming roller shaft and the lower forming roller shaft will receive a certain pressure, resulting in the deformation of the upper forming roller shaft and the lower forming roller shaft. The knuckle is connected with the power system, which can avoid the damage of the rim ring roll forming equipment caused by the deformation of the upper forming roller shaft and the lower forming roller shaf...

Embodiment 3

[0038]This embodiment is an improved embodiment based on the first embodiment. In the rim ring rolling forming equipment, the output shaft of the first motor is connected to a transmission shaft through a third universal joint, and the transmission The shaft is connected to the upper forming roller shaft through the fourth universal joint, and the transmission shaft includes a telescopic sleeve for adjusting the length of the transmission shaft. When the upper forming roller 2 moves upward, the telescopic sleeve Elongation increases the length of the transmission shaft and maintains the power connection between the upper forming roller 2 and the output shaft of the first motor.

[0039] The rim ring rolling forming equipment further includes a fourth motor, the output shaft of the fourth motor is respectively connected to the upper forming roll and the lower forming roll through a transmission device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com