Control method of universal conversion integrated gas circuit module

A control method and integrated gas technology, applied in the direction of manufacturing tools, gas flame welding equipment, auxiliary devices, etc., can solve problems such as many fault points and hidden dangers, difficult transportation, waste of manufacturing costs, etc., to save gas consumption of welding torches and equipment maintenance Simple, convenient and fast interchangeable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

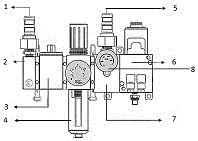

[0023] Combine below figure 1 , To further explain the present invention:

[0024] Such as figure 1 As shown, a universal conversion integrated gas circuit module includes an air inlet pagoda head 1, an air inlet sealing connector 2, a three-way valve 3, a filter pressure regulating valve 4, a welding gun pagoda head 5, a solenoid valve 6 and a gas distribution Block 7, the air inlet pagoda head 1 is installed on the top of the air inlet sealing connector 2, and the welding gun pagoda head 5 is installed on the gas distribution block 7. The horizontal two end faces of the three-way valve 3 are respectively connected with the air inlet sealing connector 2 and the filter adjustment One mounting surface of the pressure valve 4 is connected by plane sealing, and the two horizontal end surfaces of the gas distribution block 7 are respectively connected with the other mounting surface of the filter pressure regulating valve 4 and the solenoid valve 6 by plane sealing.

[0025] Plane se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com