Welding tool for aircraft auxiliary oil tank shell body annular welding seam

A technology of annular welding seam and welding tooling is applied in the field of welding tooling of annular welding seam of aircraft auxiliary fuel tank shell. Impermeability or burn-through, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

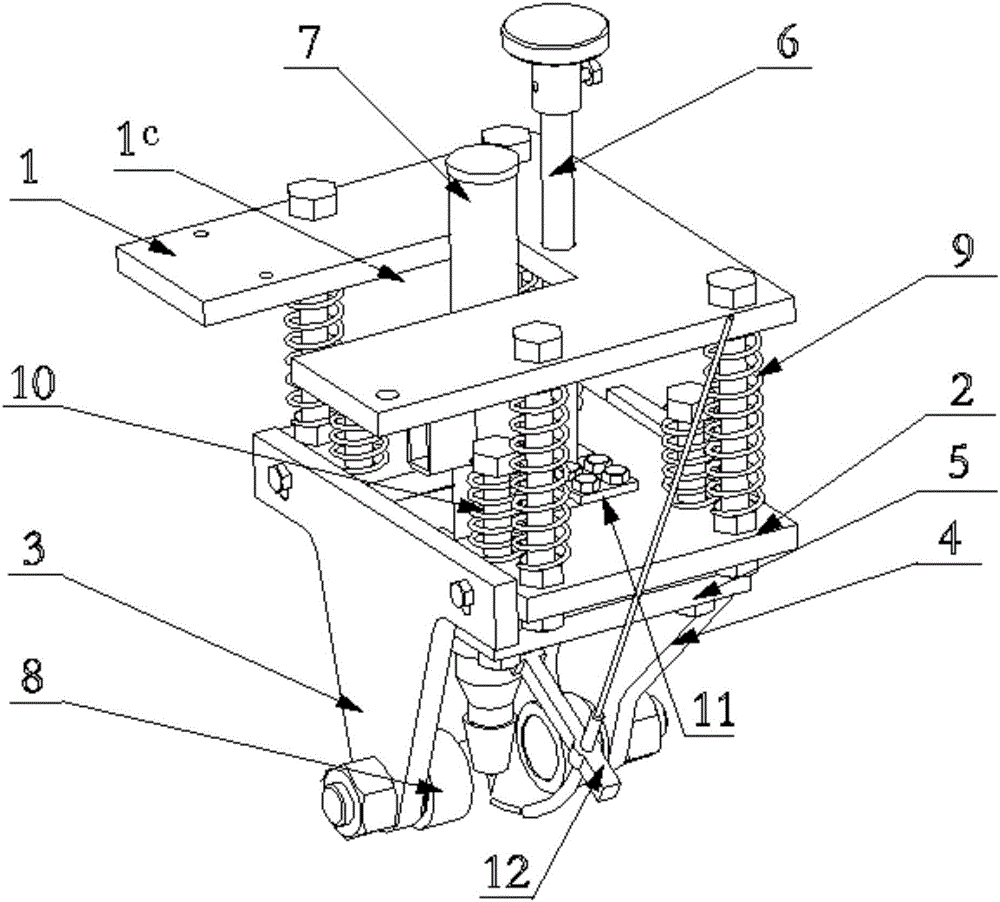

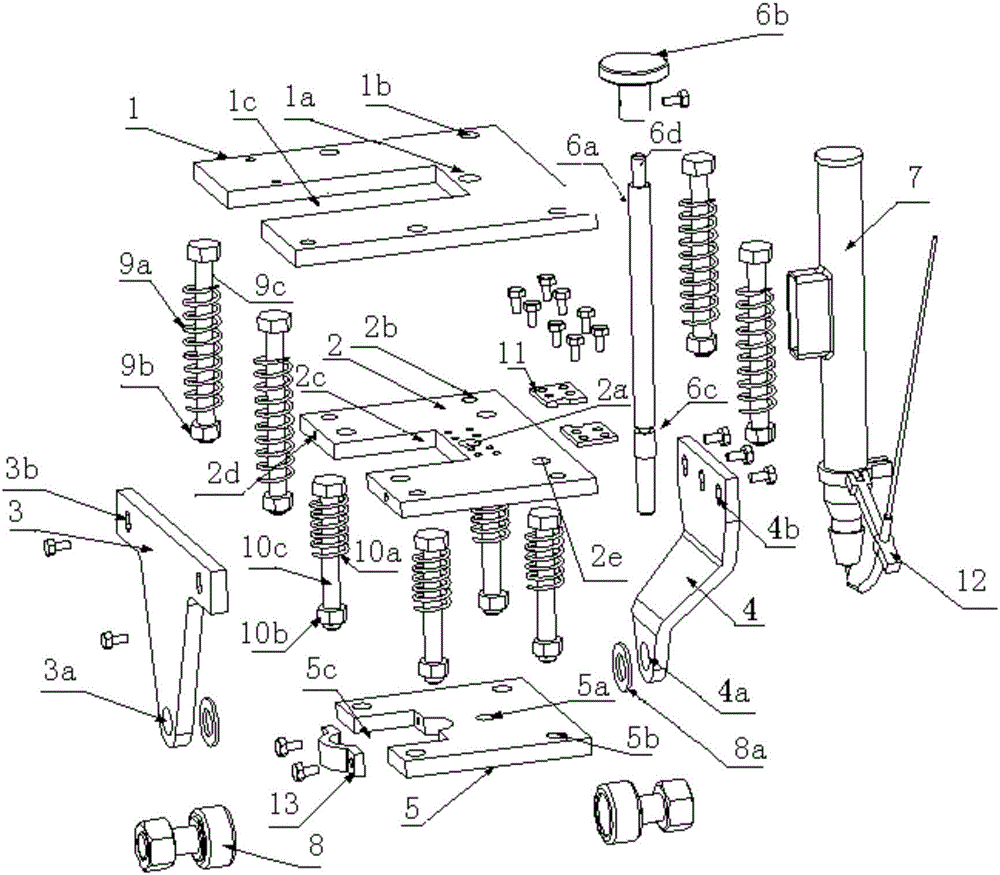

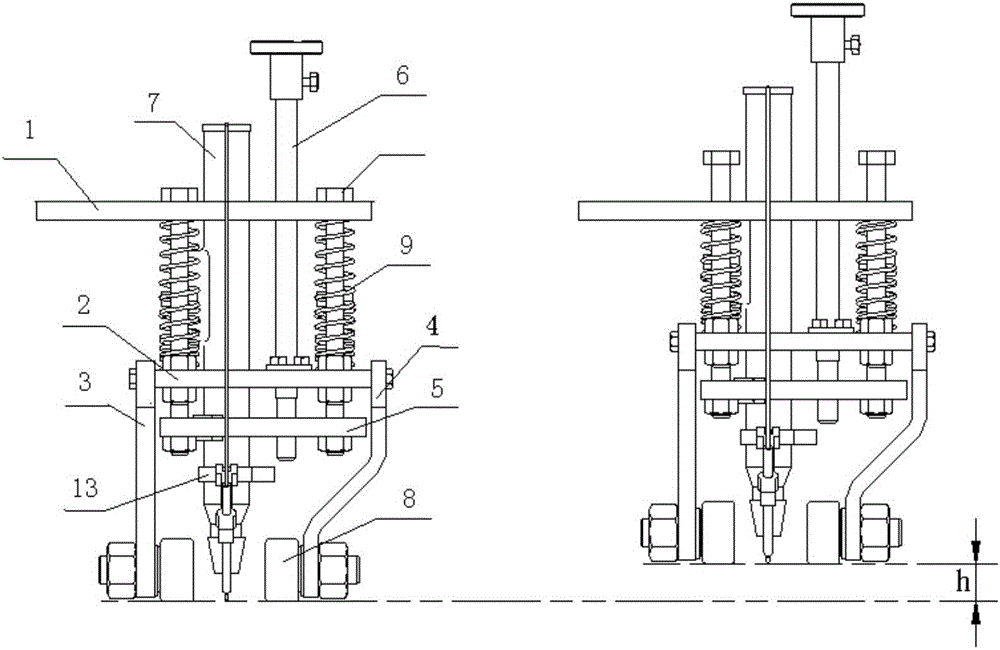

[0021] The present invention will be described in further detail below. see Figure 1 to Figure 5 , a welding tool for the annular weld of an aircraft auxiliary fuel tank shell, characterized in that it consists of a connecting plate 1, a floating plate 2, a left bracket 3 and a right bracket 4, a trimming plate 5, a trimming rod assembly 6, and 2 guide wheel assemblies 8. Composed of 4 outer guide post assemblies 9, 4 inner guide post assemblies 10, 2 clamping plates 11 and welding torch fixing pressure plate assembly 13;

[0022] The connection plate 1 is a rectangular plate placed horizontally, the left and right direction is the long side, and the front and rear direction is the wide side. There is a connection plate welding torch relief groove 1c on the left wide side of the connection plate 1, and the connection plate welding torch relief groove 1c is along the The width direction of the connection plate 1 is centered, and the connection plate welding torch relief groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com