ERW prewelding method for LSAW steel pipe production

A steel pipe, pre-welding technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low production efficiency, high production cost, inability to realize continuous assembly line operation, etc., and achieve high production efficiency, precise control, and operability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

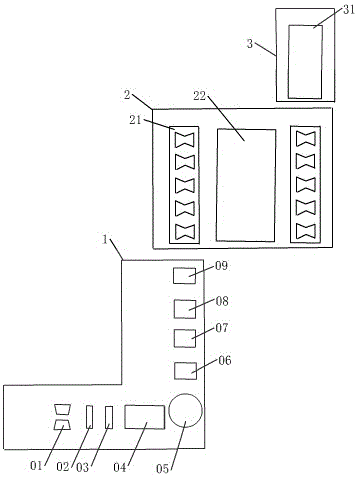

[0012] according to figure 1 As shown, there are double cone uncoiling device 01, leveling device 02, shear butt welding device 03, transition device 04, loop storage device 05, pre-bending forming device 06, row forming device 07, finishing forming device 08 and high-frequency pre-welding device 09 are combined to form ERW production line 1. ERW production line is connected to ERW / LSAW transition device 2. ERW / LSAW transition device 22 is provided on the ERW / LSAW transition device, and on both sides of ERW / LSAW transition device The ERW / LSAW transitional roller table 21 is respectively installed, and the LSAW production line 3 is connected to the end of one side of the ERW / LSAW transitional roller table, and the LSAW welding device 31 is arranged on the LSAW production line.

[0013] Control flow:

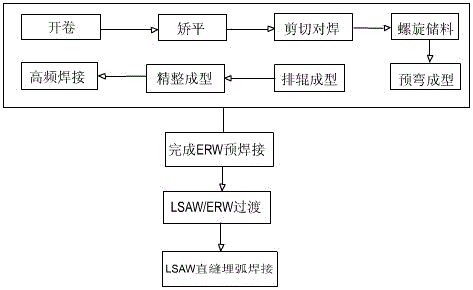

[0014] according to figure 2 As shown, the tube coils are first uncoiled, then leveled and sheared butt welded. After sheared butt welded, they are stored in a spiral, stacked,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com