Grinding and thinning device of wafers

A technology of wafer and worktable, applied in grinding machine, grinding frame, grinding bed and other directions, can solve the problems of affecting the quality of the wafer and the thickness of the lens, and achieve high safety performance, low work intensity and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

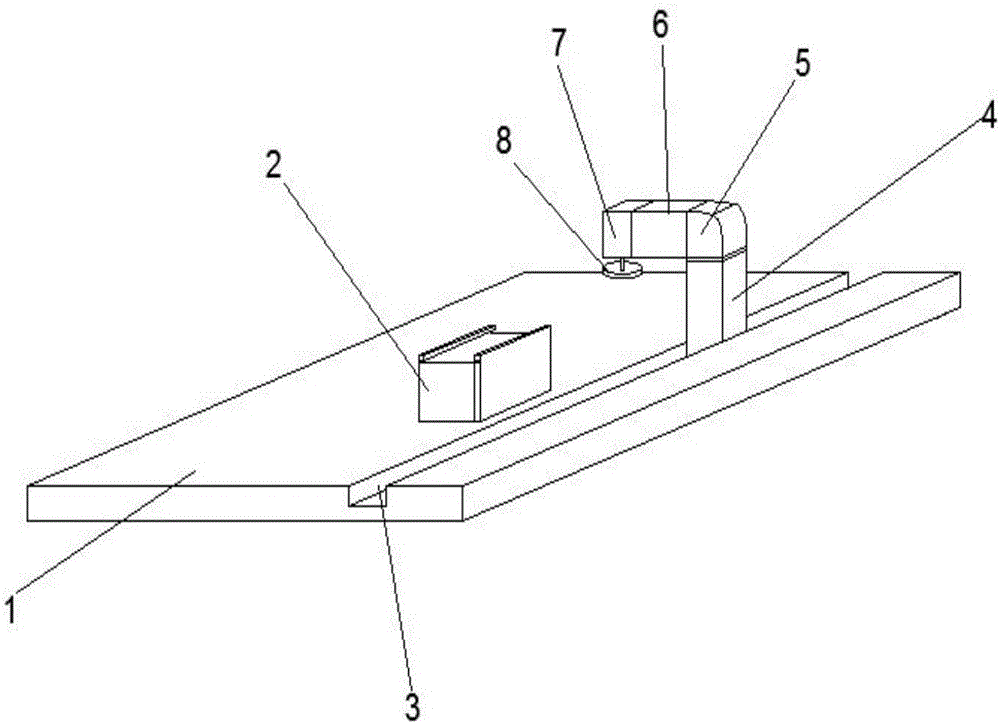

[0013] In order to achieve the required technical effect of the present invention, the present invention selects the following embodiments: a wafer grinding and thinning device, including a workbench, the workbench is provided with a fixing seat, and the fixing seat is provided with a fixing slot. The workbench is provided with a moving slot, the moving slot is provided with a moving bracket, the moving bracket is provided with a rotating shaft, the moving bracket is provided with a mechanical arm, one end of the mechanical arm is connected to the rotating shaft, and the other end of the mechanical arm is A motor is provided, and the motor is provided with a grinding wheel shaft, and the grinding wheel shaft is connected with a grinding wheel.

[0014] Preferably, the setting is at the central position of the workbench.

[0015] Preferably, there are protrusions on both sides of the upper surface of the workbench, the protrusions are provided with grooves, and the grooves, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap