Demoulding device for bumper mold

A technology of demoulding device and bumper, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of inability to arrange the space position, difficulty in picking up parts, reducing the demoulding efficiency, etc., and achieves a simple and compact internal structure of the mold. The effect of reducing mold cost and quick demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

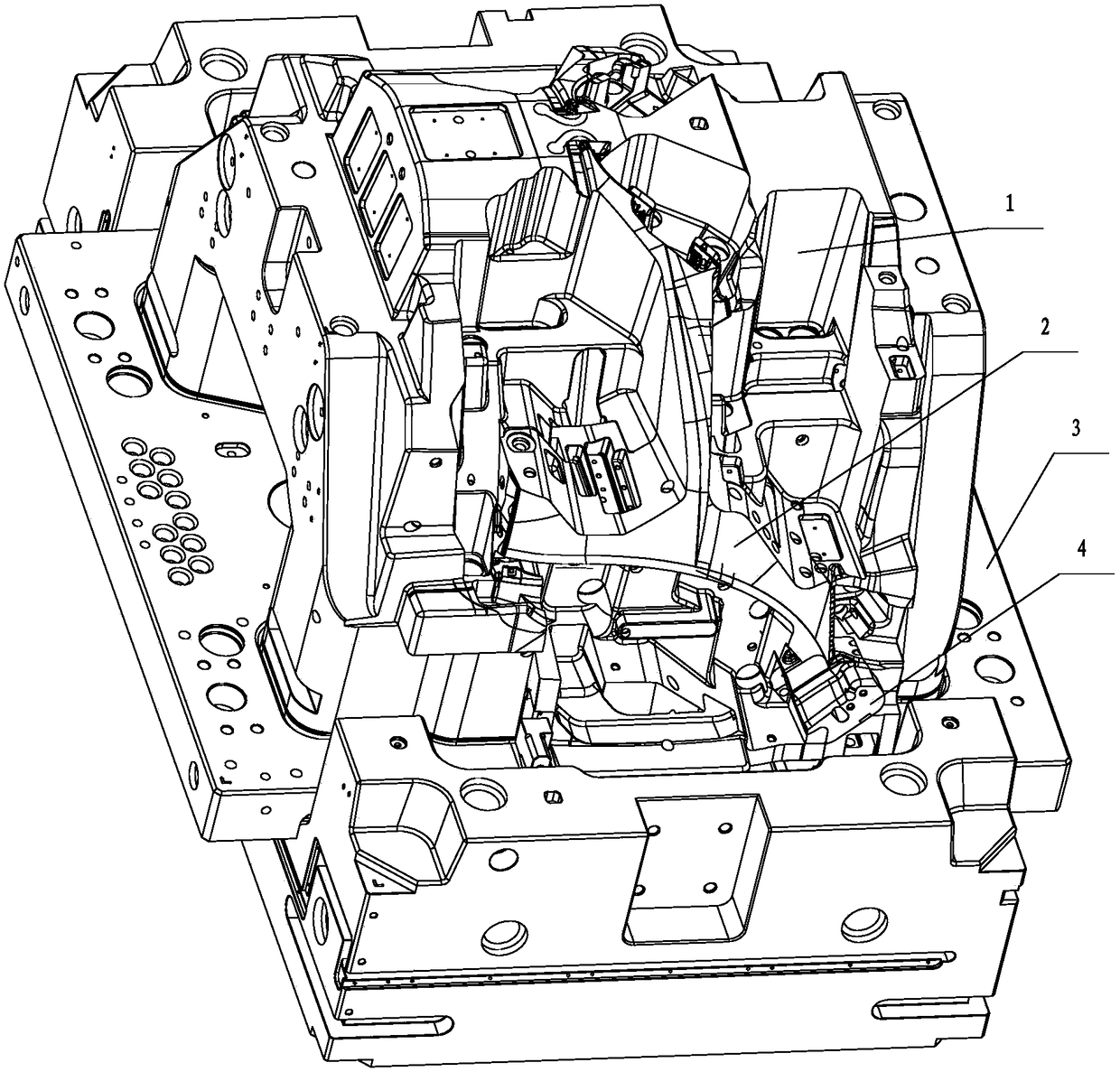

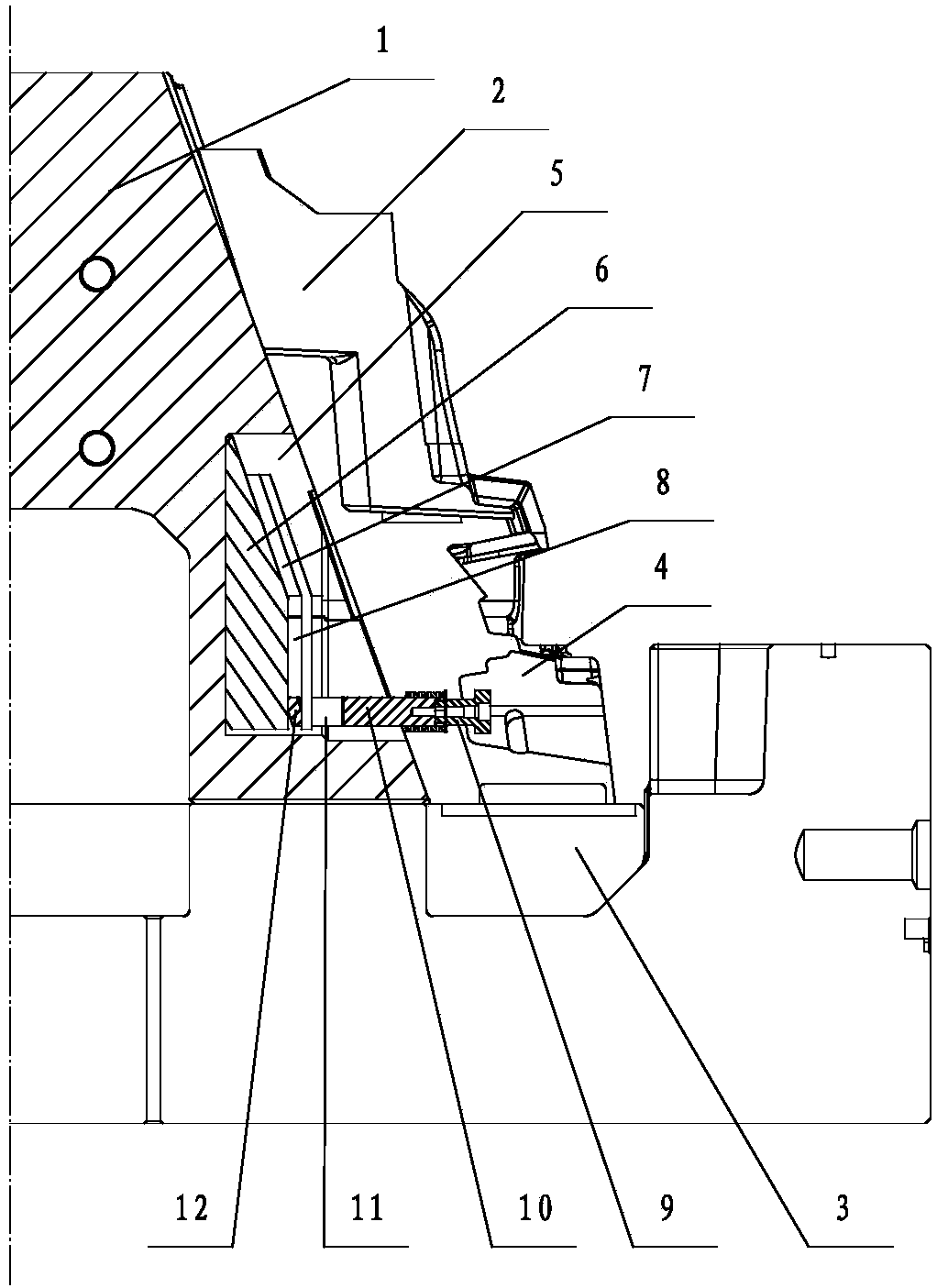

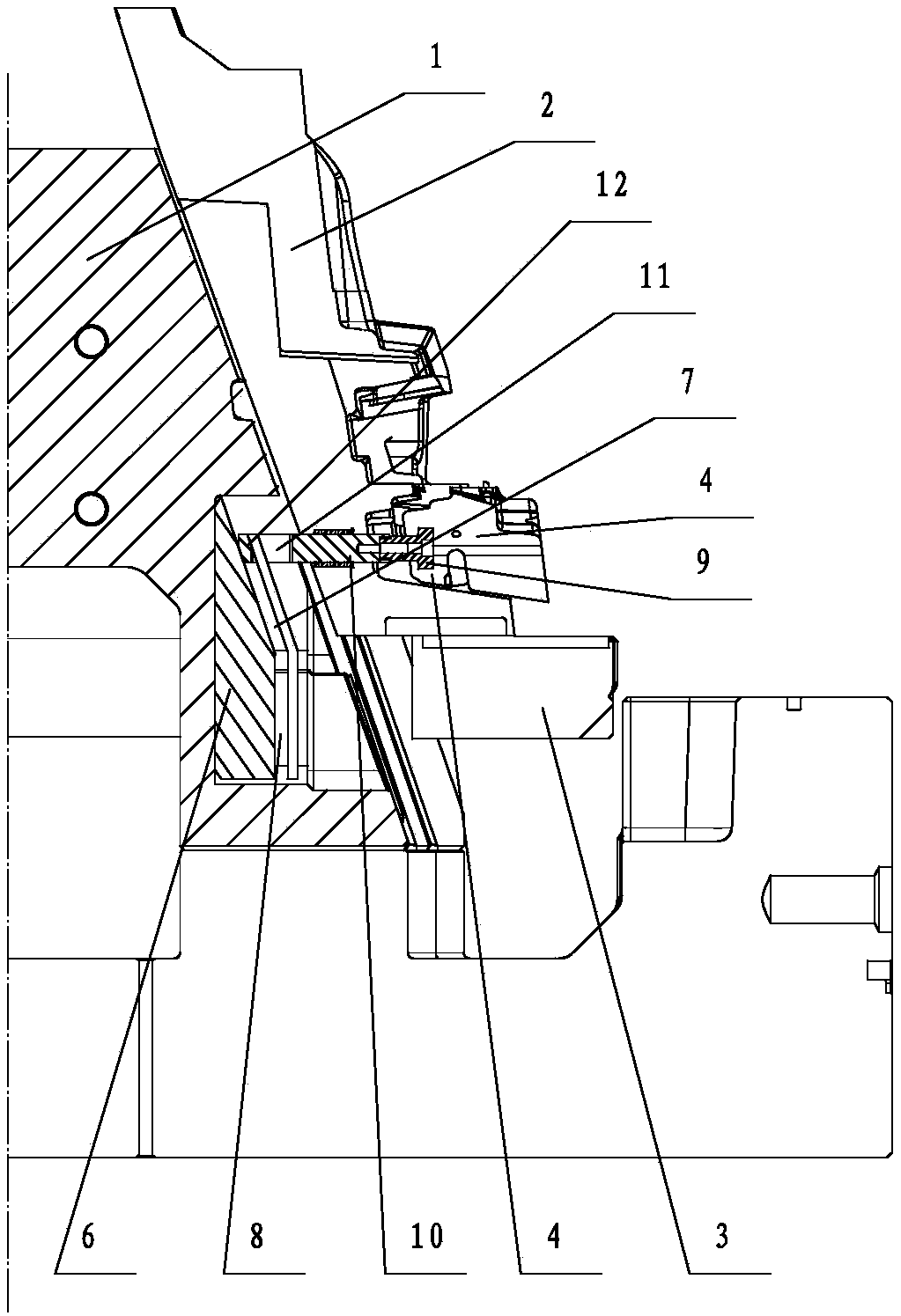

[0023] Depend on Figure 1 to Figure 8 As can be seen from the structural schematic diagram of the demoulding device of the bumper mold of the present invention, it includes a large inclined roof mechanism, a small inclined roof mechanism and a large inclined roof mechanism and a small inclined roof mechanism for the automobile bumper lampshade panel. The movable mold insert core 1. The large slanted top block 2 in the large slanted top mechanism is slidably connected to the movable mold insert core 1 through the drive of the ejector plate 3 in the mold, and the small slanted top block 4 in the small slanted top mechanism is fitted on the large slanted top In the block 2, the small inclined roof guide rod 10 in the small inclined roof mechanism is slidably connected in the large inclined roof block 2, and the end of the small incline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com