a barrel of water

A barreled water and bucket technology, applied in the field of barreled water buckets, can solve the problems of high cost, troublesome water change, troublesome sealing, etc., and achieve the effects of fast and convenient assembly and packaging, preventing bacteria from entering, and convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

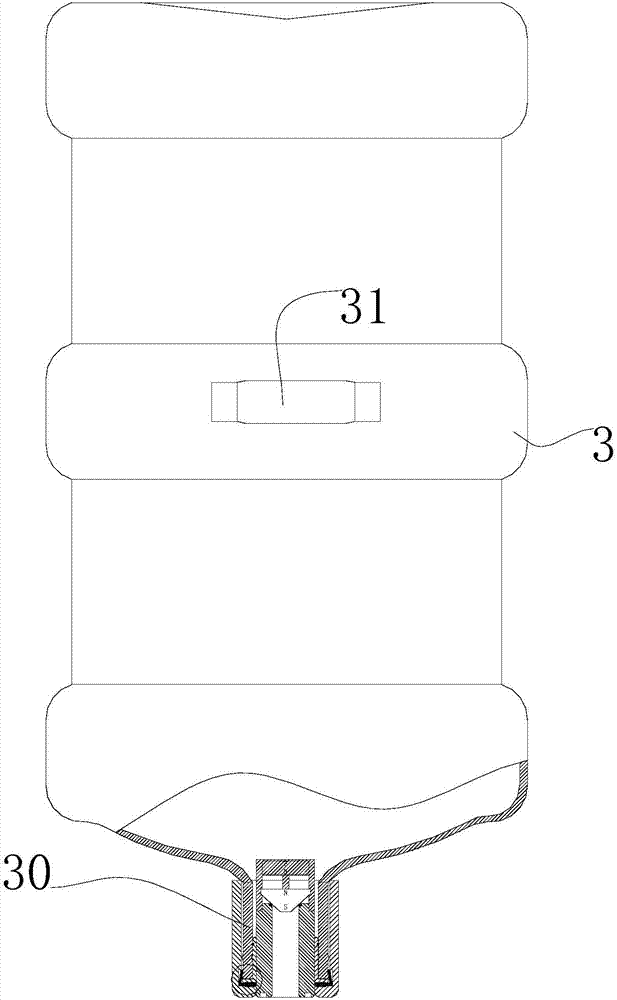

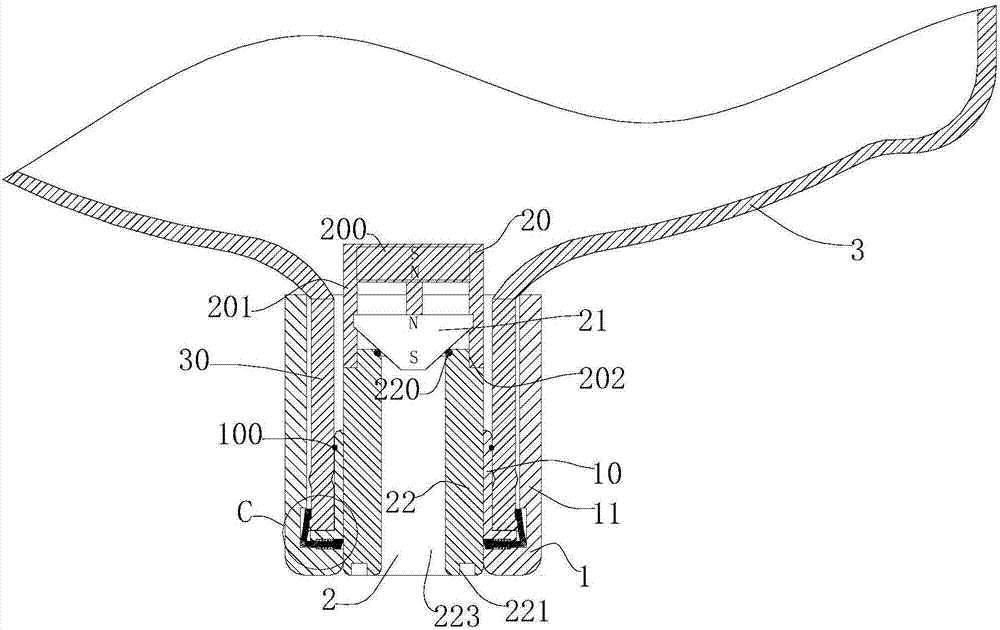

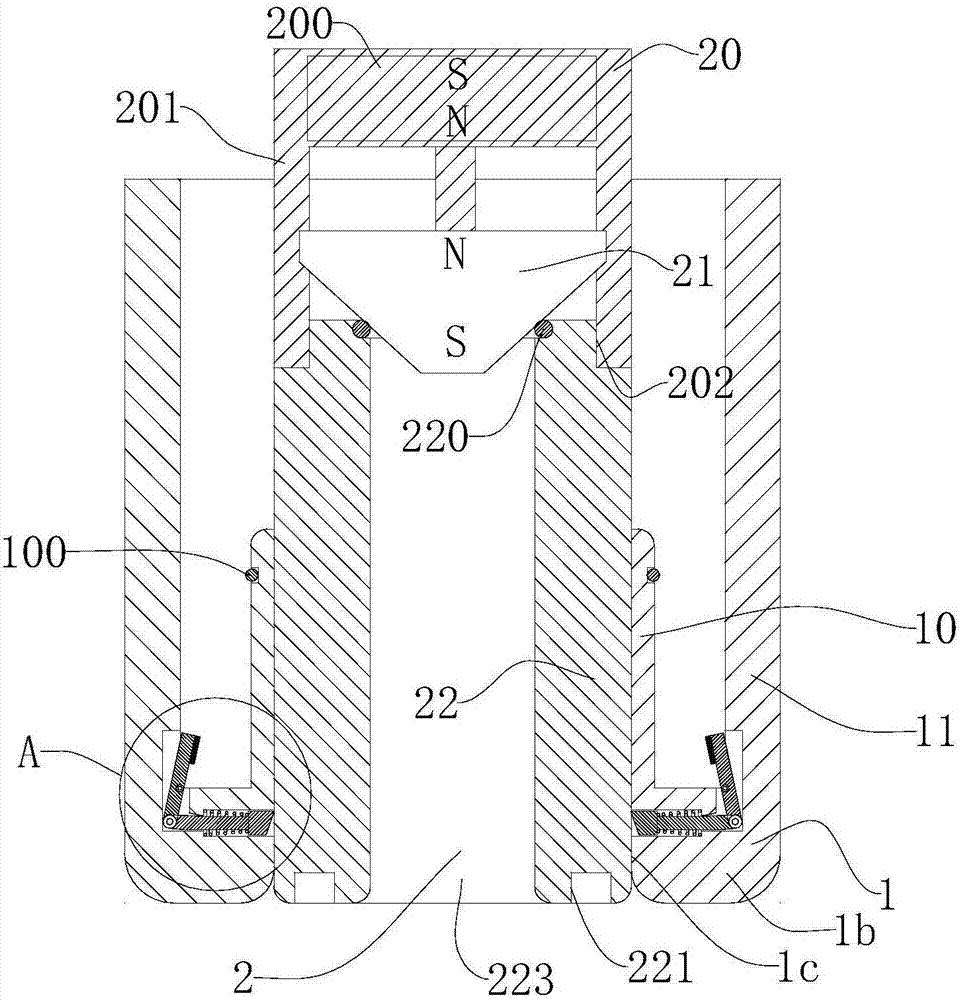

[0036] Such as Figure 1-8 A kind of bottled water bucket shown, it comprises bucket body 3 and bucket packing head, and bucket body 3 middle part is provided with handle 31, and handle 31 quantity is one, and is arranged on the middle part of bucket body 3, and handle 31 The length direction is parallel to the cross section of the bucket body 3 . When the length direction of the handle 31 is parallel to the cross-section of the bucket body 3, the barreled water bucket can be turned upside down by holding it in reverse, and it is convenient and labor-saving to put into the water dispenser. Therefore, this handle 31 is not only convenient for manual handling, but also convenient. Load into the water dispenser.

[0037] The above-mentioned water bucket packaging head is composed of a hard shell part 1 and a hard leaking core part 2 for fixing the mouth part 30 of the drinking water bucket. Wherein, the hard shell part 1 includes a peripheral part 11 surrounding the outer wall ...

Embodiment 2

[0048] The sealing head on the drinking water barrel of another structure, such as Figure 9 Shown, wherein the difference with embodiment 1 is:

[0049] The outer end surface of the push rod 14 is an inclined surface facing upwards, and the inclined surface of the outer end of the push rod 14 corresponds to the lower end of the clamping part 16; Position to the torsion spring 19 of the slotted hole 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com