Coating mechanism for metalized film processing

A metallized film, evaporation coating technology, applied in metal material coating process, sputtering coating, ion implantation coating and other directions, can solve the problem of low surface temperature of insulating film, can not meet the three-dimensional adjustment, inconvenient automatic adjustment and other problems, to achieve the effect of adjustable coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further describe the present invention, it will be further described in the following embodiments.

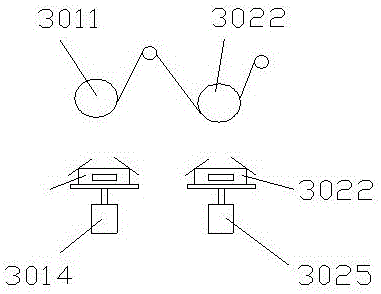

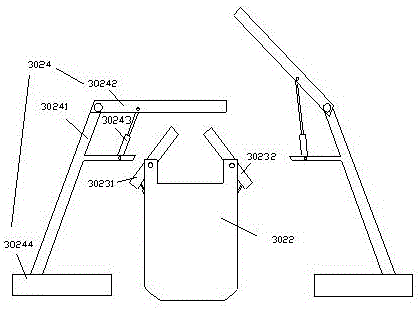

[0024] Such as figure 1 As shown, the coating mechanism includes a first evaporation coating device, including a first evaporation drum 3011, a first evaporation boat 3012. The first evaporation boat 3012 is arranged below the first evaporation drum 3011. The top opening area of the first evaporation boat 3012 is provided with a first movable plate assembly that controls the size of the opening of the first evaporation boat 3012.

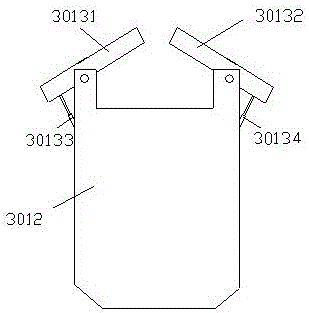

[0025] Such as figure 2 As shown, as a preferred solution: the first movable panel assembly includes a first left movable panel 30131, a first right movable panel 30132, a first left telescopic device 30133, and a first right telescopic device 30134. The lower end of the first left movable plate 30131 is hinged to the end of the top of the first evaporation boat 3012, and the higher end is the free end. The fixed end of the first l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com