A kind of patch, coating equipment for preparing patch and preparation method thereof

A patch and coating technology, which is applied in medical science, injection devices, prostheses, etc., can solve the problems of material convergence, patch surface roughness, and influence on coating uniformity, so as to avoid coatings that are too thick or too thin , The surface of the patch is smooth and uniform, and the effect of solving the uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

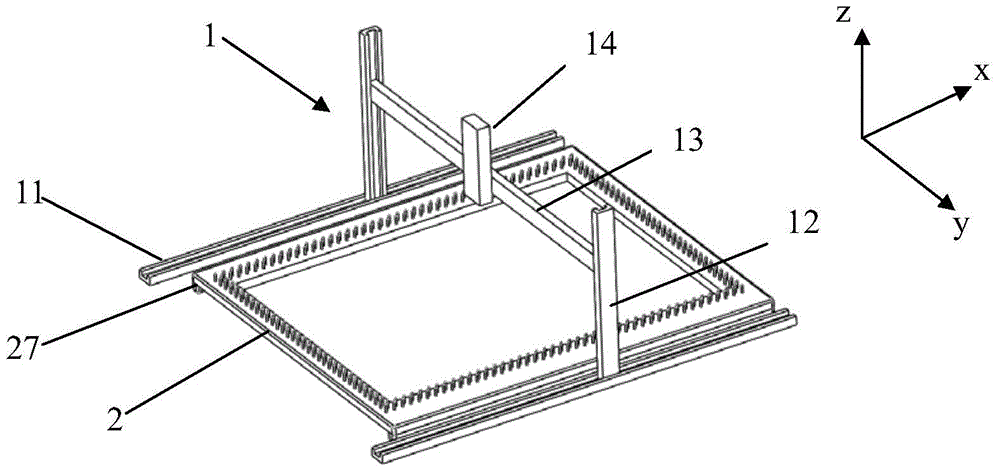

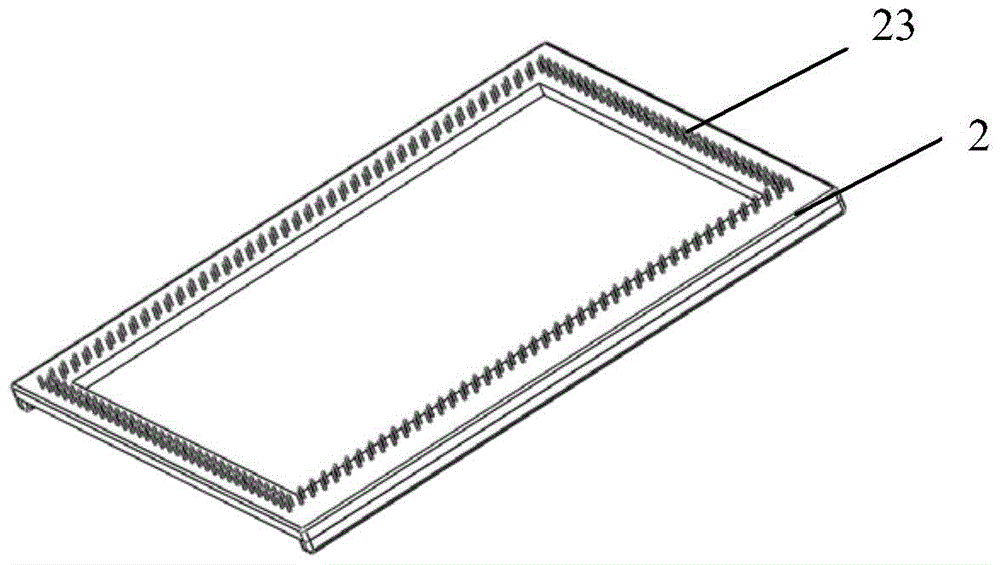

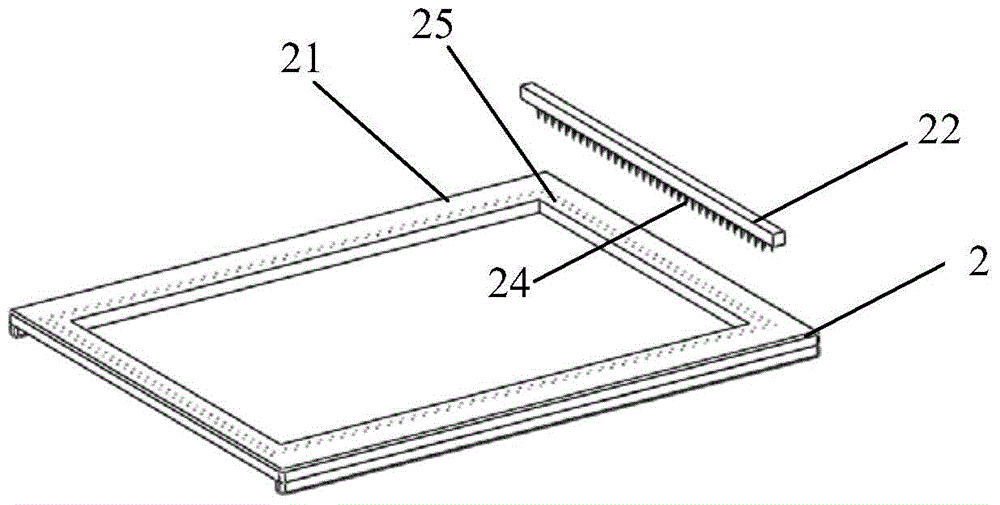

[0045] The polypropylene patch material was washed with 1% Triton and deionized water by ultrasonic vibration for 15 minutes, dried and set aside. Mix the two together according to the ratio of fish oil:cross-linking agent=100:21, react at 100°C for 40 hours to obtain a coating solution, take out the coating solution, and set aside. Fill the coating solution into the syringe in the fume hood, adjust the injection rate of the coating solution in the syringe to 0.08ml / min and the compressed gas pressure to 8psi; fix the patch material on the polytetrafluoroethylene fixture, and use Figure 2 Clamped by the supportable fixture in (a), adjust the distance between the nozzle 14 and the fixture 2 to be 30cm; adjust the number of reciprocating movements of the movable nozzle to 15 times, start the spraying process, and the coating solution is sprayed onto the patch material through the movable nozzle surface to form a patch; remove the patch from the polytetrafluoroethylene fixture, p...

Embodiment 2

[0047] The bare polyester patch material with a size of 10cm×10cm was washed with 3% Triton and deionized water by ultrasonic vibration for 20 minutes, dried and set aside. Mix the two together according to the ratio of fish oil:cross-linking agent=100:15, react at 90°C for 60h, take out the coating solution, and set aside. Fill the coating solution into the syringe in the fume hood, adjust the injection rate of the coating solution in the syringe to 0.01ml / min and the compressed gas pressure to 3psi; fix the patch material on the polyvinylidene chloride fixture, and use Figure 2 Clamped by the supportable fixture in (b), adjust the distance between the nozzle 14 and the fixture 2 to be 10cm; adjust the number of reciprocating movements of the movable nozzle to be 20 times, start the spraying process, and the coating solution is sprayed to the patch material through the movable nozzle surface to form a patch; remove the patch from the polyvinylidene chloride fixture, put it in...

Embodiment 3

[0049] The expanded polytetrafluoroethylene patch material was washed with 1% Triton and deionized water by ultrasonic vibration for 15 minutes, dried and set aside. Mix the two together according to the ratio of fish oil:cross-linking agent=100:30, react at 110°C for 48 hours, take out the coating solution, and set aside. In the fume hood, the coating solution is poured into the syringe, and the injection speed of the coating solution in the syringe is adjusted to be 0.008ml / min and the compressed gas pressure is 5psi; Clamped by the supportable fixture in 2(c), the distance between the nozzle 14 and the fixture 2 is adjusted to be 20cm; the number of reciprocating movements of the movable nozzle is adjusted to 30 times, and the spraying process is started, and the coating solution is sprayed to the patch via the movable nozzle A patch is formed on the surface of the material; the patch is removed from the polytetrafluoroethylene plate, placed in an oven, and dried at 70° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com