A precision equipment refurbishment production line and process

A precision equipment and production line technology, applied in the direction of metal material coating process, etc., can solve the problems of no continuous use, unusable, expensive imported precision equipment, etc., to improve anti-oxidation ability, prolong service life, The effect of restoring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

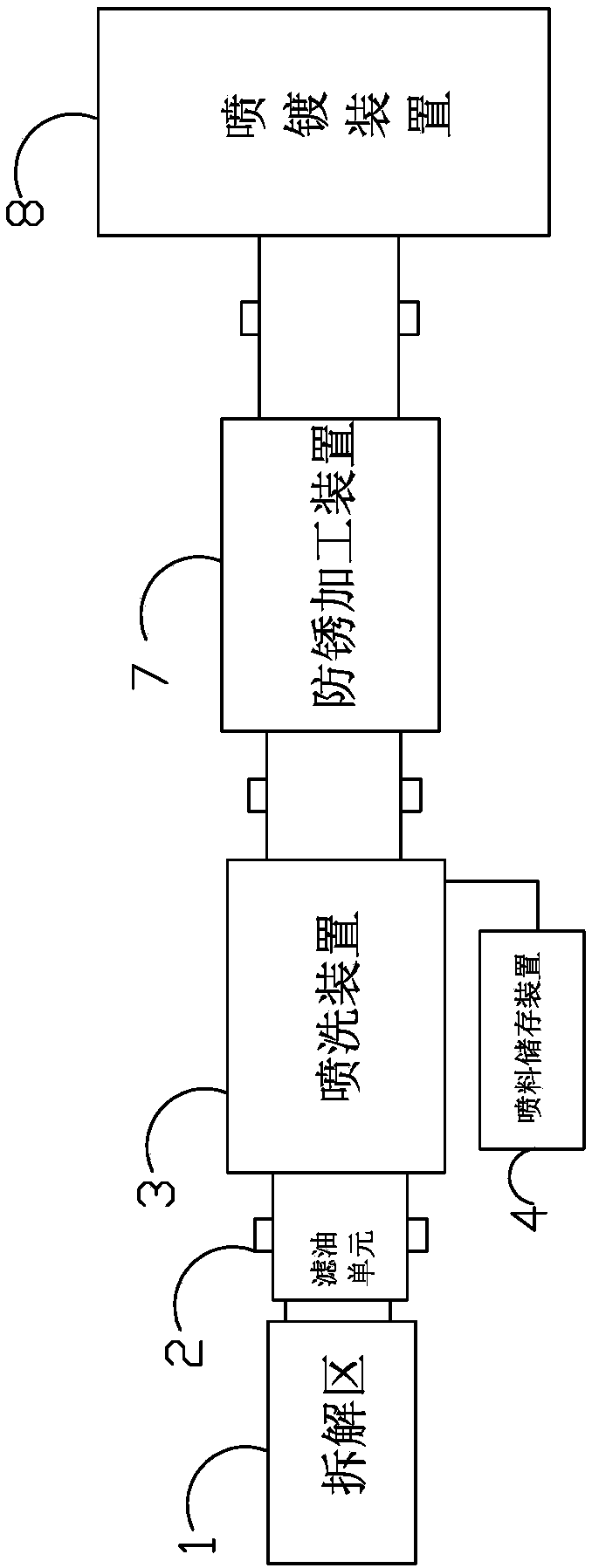

[0024] see figure 1 , A precision equipment refurbishment production line of the present invention includes: a dismantling area 1, an oil filter unit 2, a spray washing device 3, a material spray storage device 4, an antirust processing device 7, and a spray coating device 8. Specifically, when the precision equipment is disassembled into parts on the working platform in the dismantling area 1, some metal parts will be placed in the oil filter unit 2, wherein the oil filter unit 2 is mesh-shaped and adopts a flexible Because the metal parts of precision equipment usually require high dimensional accuracy, in order to avoid damage to the metal parts while dripping the oil of the metal parts, the mesh-shaped part bearing area in this embodiment is preferably plastic / resin material. Further, after part of the oil on the surface of the metal part is filtered, it enters the spray cleaning device 3 for spray cleaning to remove impurities such as oxides, rust, and stains on the surf...

Embodiment 2

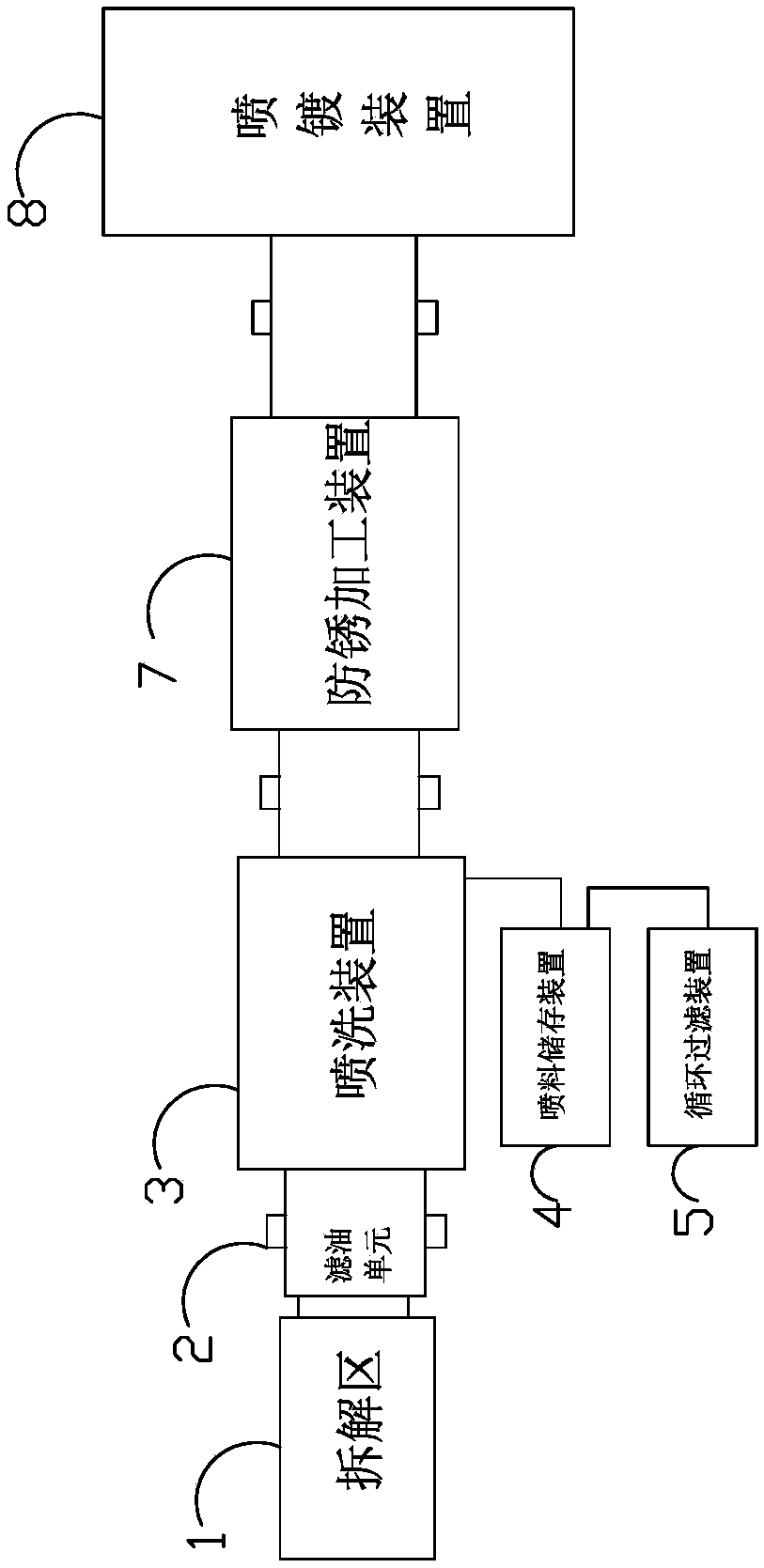

[0028] see figure 2 , A precision equipment refurbishment production line of the present invention includes: a dismantling area 1, an oil filter unit 2, a spray washing device 3, a material spray storage device 4, an antirust processing device 7, a spray plating device 8, and a circulation filter device 5. Specifically, when the precision equipment is disassembled into parts on the working platform in the dismantling area 1, some metal parts will be placed in the oil filter unit 2, wherein the oil filter unit 2 is mesh-shaped and adopts a flexible Because the metal parts of precision equipment usually require high dimensional accuracy, in order to avoid damage to the metal parts while dripping the oil of the metal parts, the mesh-shaped part bearing area in this embodiment is preferably plastic / resin material. Further, after part of the oil on the surface of the metal part is filtered, it enters the spray cleaning device 3 for spray cleaning to remove impurities such as oxid...

Embodiment 3

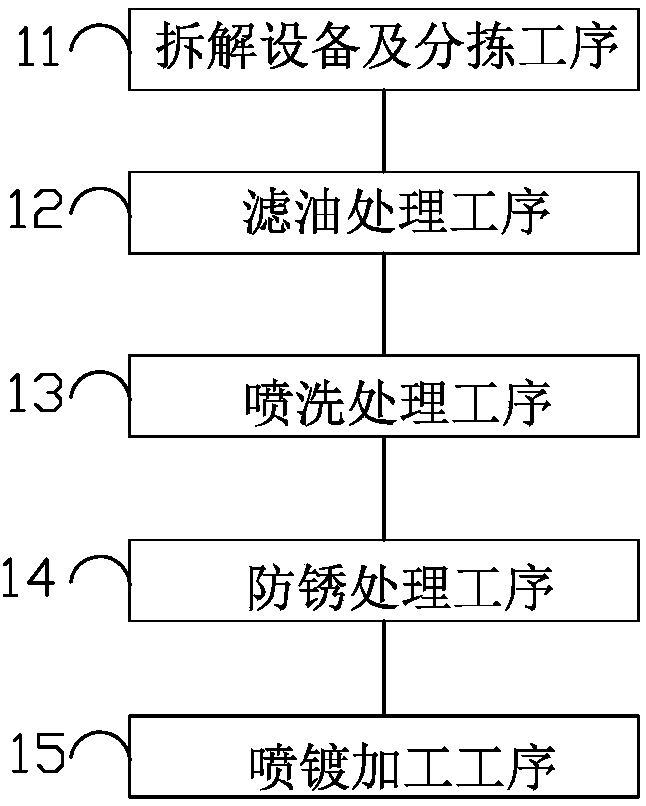

[0034] see image 3 , a kind of renovation process of precision equipment of the present invention mainly comprises steps as follows:

[0035] Dismantling equipment and sorting process 11: oil filtering process 12; spraying process 13; rust prevention process 14; spraying process 15.

[0036] Specifically, the dismantling equipment and sorting process 11 sort out the metal parts after dismantling the precision equipment, and through the oil filtering process 12, a part of the engine oil is preliminarily filtered out in a trickling manner, so as to prepare for subsequent spraying. Washing treatment process 13 improves spray cleaning efficiency, wherein this spray washing treatment process 13 comprises: with 100 ~ 250 purpose glass sand and pH value weakly alkaline water at 7, with glass sand 20%, water 80% ratio is allocated into The spraying medium is sprayed to the surface of the metal part at a pressure of 0.3 MPa. After the impurities on the surface of the metal part are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com