Cloth roller of textile machine

A machine-rolled cloth roller and textile technology, which is applied in the field of textile machine accessories, can solve the problems of affecting cloth winding, not being easy to disassemble, and having no effect, and achieve the effects of convenient disassembly and maintenance, improved production efficiency, and tight sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

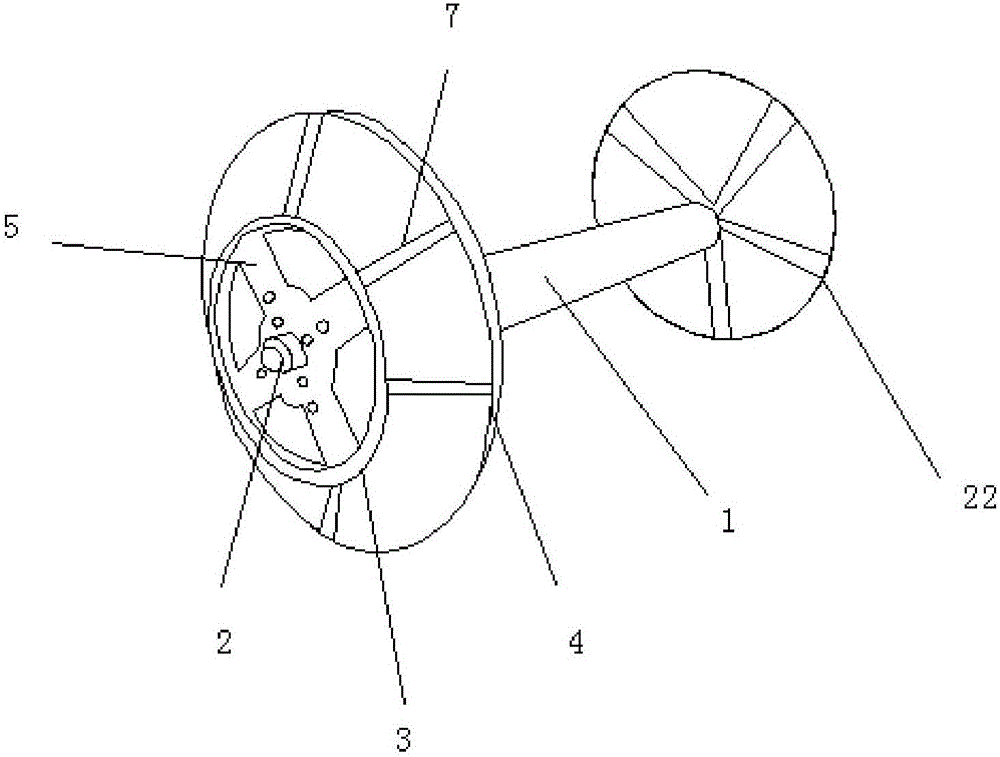

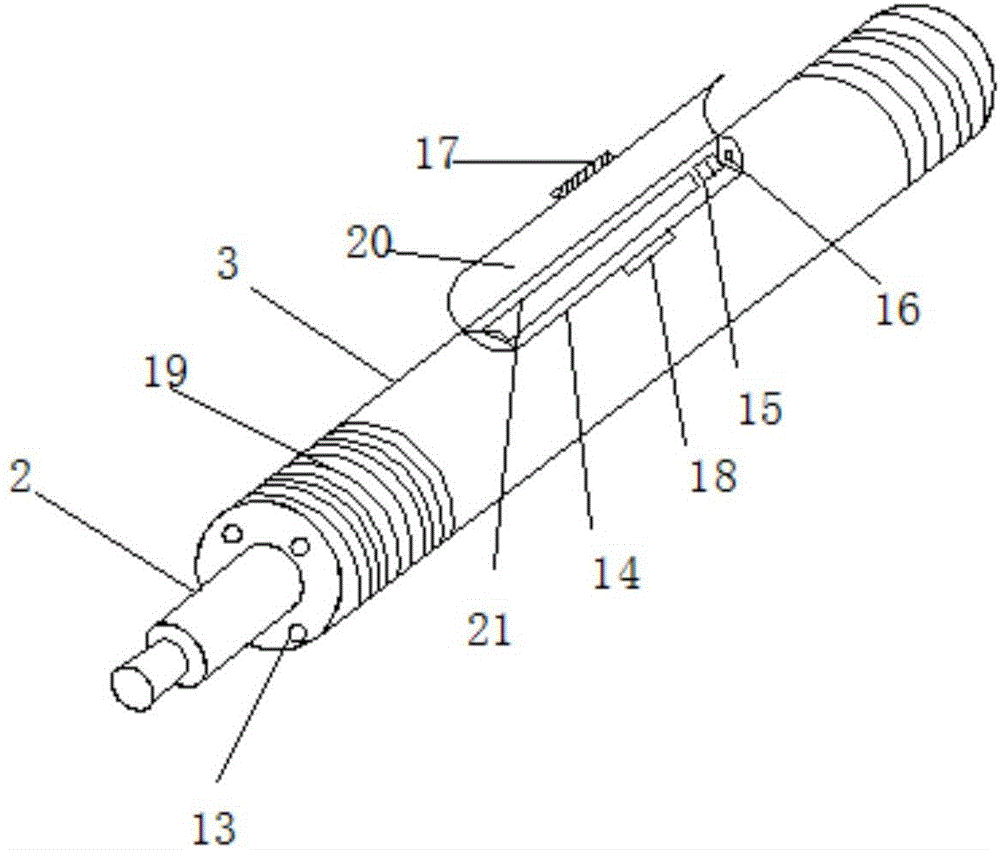

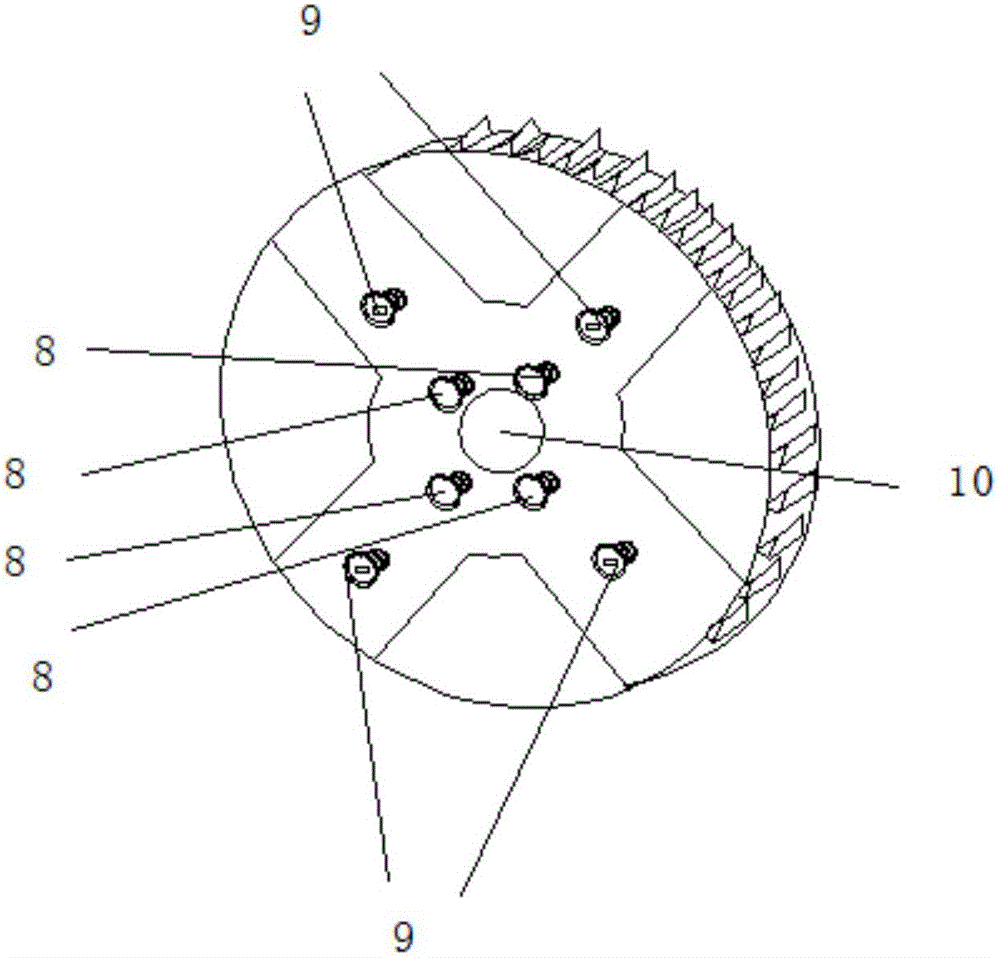

[0020] Example: see Figure 1-5 , a textile machine fabric rolling roll of the present invention comprises a carrier roller 1, a warp beam 2, a tooth disc 3, a first warp beam disc 4 and a second warp beam disc 22, and the warp beam 2 is arranged inside the carrier roller 1, And the warp shaft 2 protrudes from the end of the idler roller 1, the tooth plate 3 is sleeved on the warp shaft 2, and the tooth plate 3 is detachably connected to one end of the idler roller 1 through the first screw 8 provided on the support frame 5, The outer wall of the end of the idler 1 is provided with a threaded hole A13 compatible with the first screw 8, and the first warp beam plate 4 is composed of two parts welded by a reinforcing rib 7 and a fixing ring 6, and the fixing ring 6 is located on the In the middle of the first warp beam disc 4, a threaded through hole 11 adapted to the diameter of the idler 1 is provided in the middle of the fixed ring 6, and the first warp beam disc 4 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com