A clamp system and a sewing machine with the clamp system

A technology of clamping mechanism and clamping parts, which is applied to sewing machine components, leather product sewing machines, control devices for sewing machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] [Overall structure of sewing machine]

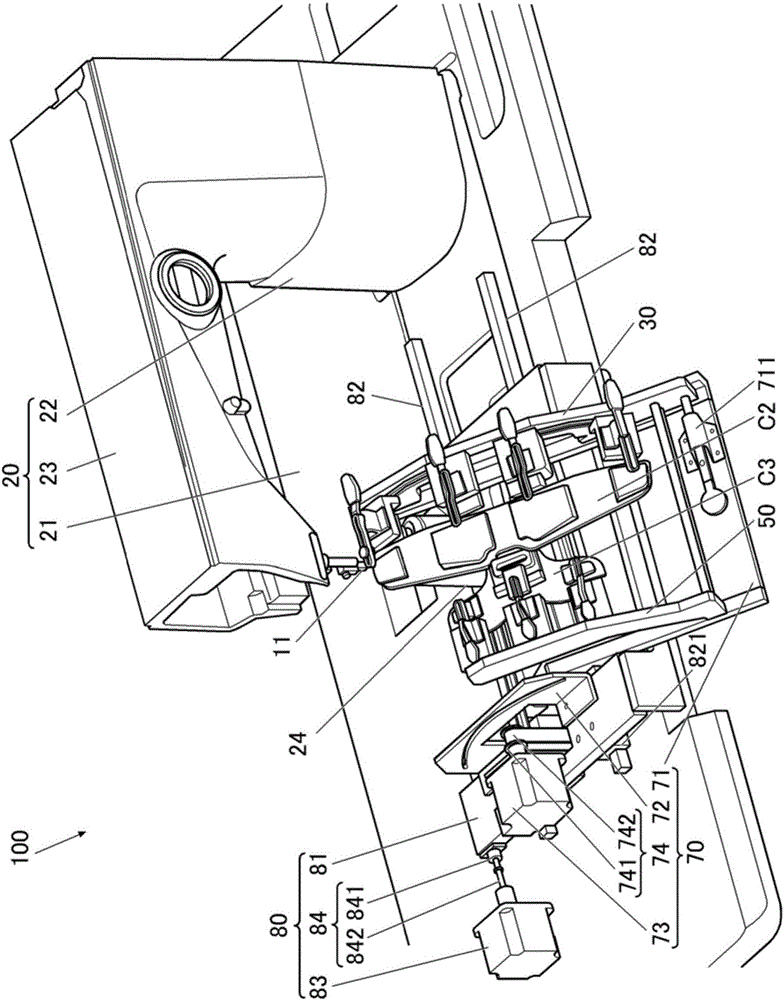

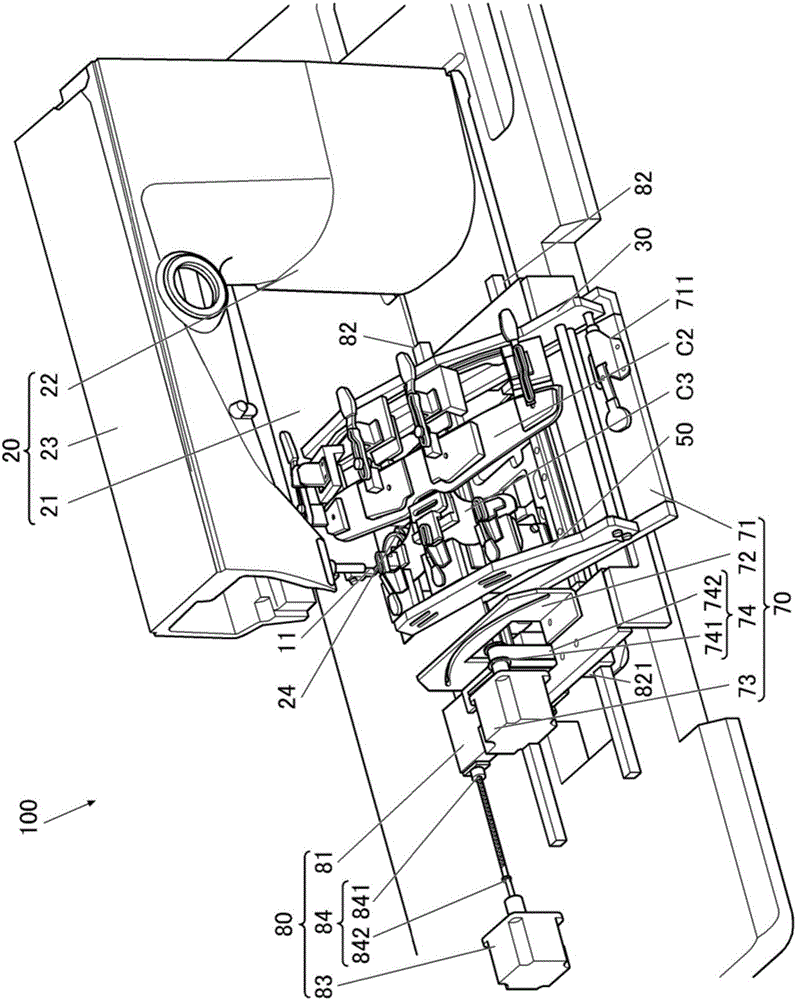

[0091] Below, based on Figure 1 to Figure 9 , the sewing machine 100 as an embodiment of the present invention will be described. The sewing machine 100 is an automatic sewing machine that uses first and second clamping mechanisms 30 and 50 suitable for holding a curved object to perform needle drop at an arbitrary position according to a predetermined sewing pattern.

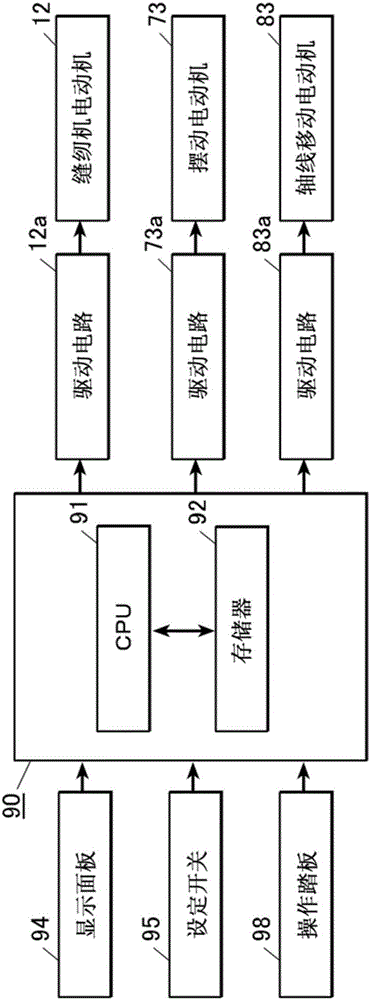

[0092] figure 1 and figure 2 It is a perspective view which omits the structure of a part of the sewing machine 100, image 3 It is a block diagram showing the control system of the sewing machine.

[0093] In the following description, the following case is exemplified, that is, for the shoe upper C1 of a ring-shaped shoe (refer to Figure 5 ), the reinforcement material C2 and the label C3 as the sewing object are sewn at the heel portion.

[0094] The above-mentioned sewing machine 100 is provided with: a needle bar which holds a sewing needle at a lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com