Rail detection trolley

A track detection and trolley technology, used in tracks, track laying, track maintenance, etc., can solve problems such as inability to achieve online detection, unsuitable handheld devices or hand-pushed trolleys, and inability to meet the requirements of rail detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In this paper, for the convenience of explanation, the left side of the driving direction of the track detection trolley following the rail repair vehicle is defined as left, the right side of the driving direction of the track detection trolley following the rail repair vehicle is defined as right, and the direction of the rail to the outside is defined as Outside, the direction of the rail to the inside is defined as inside.

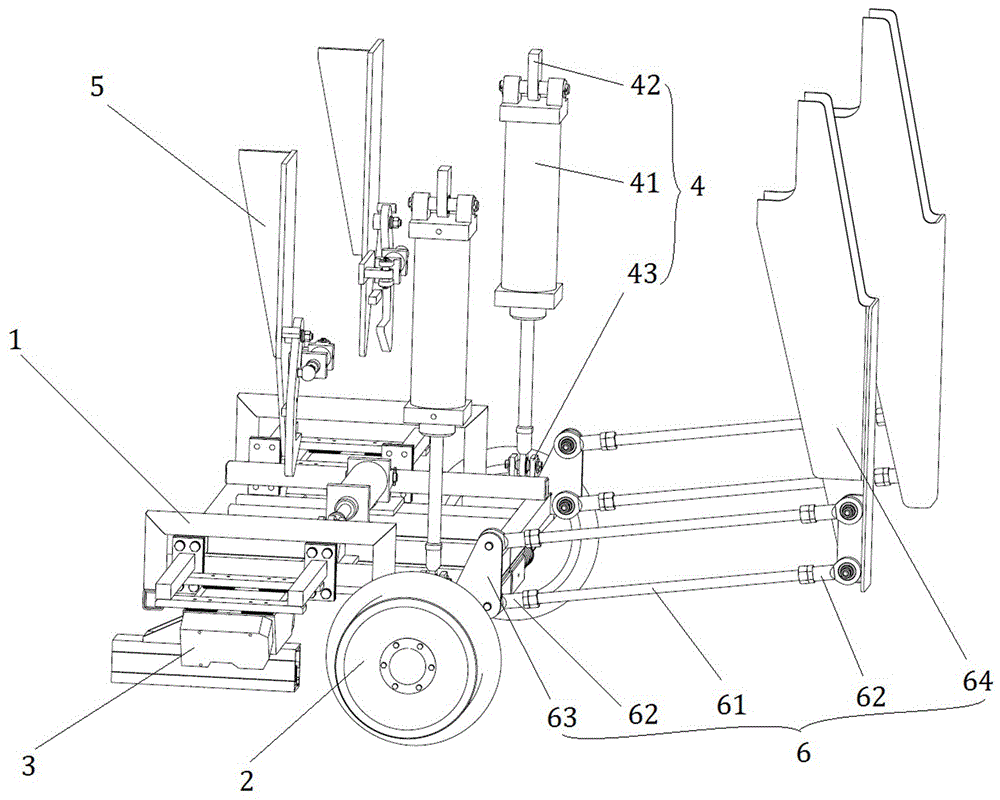

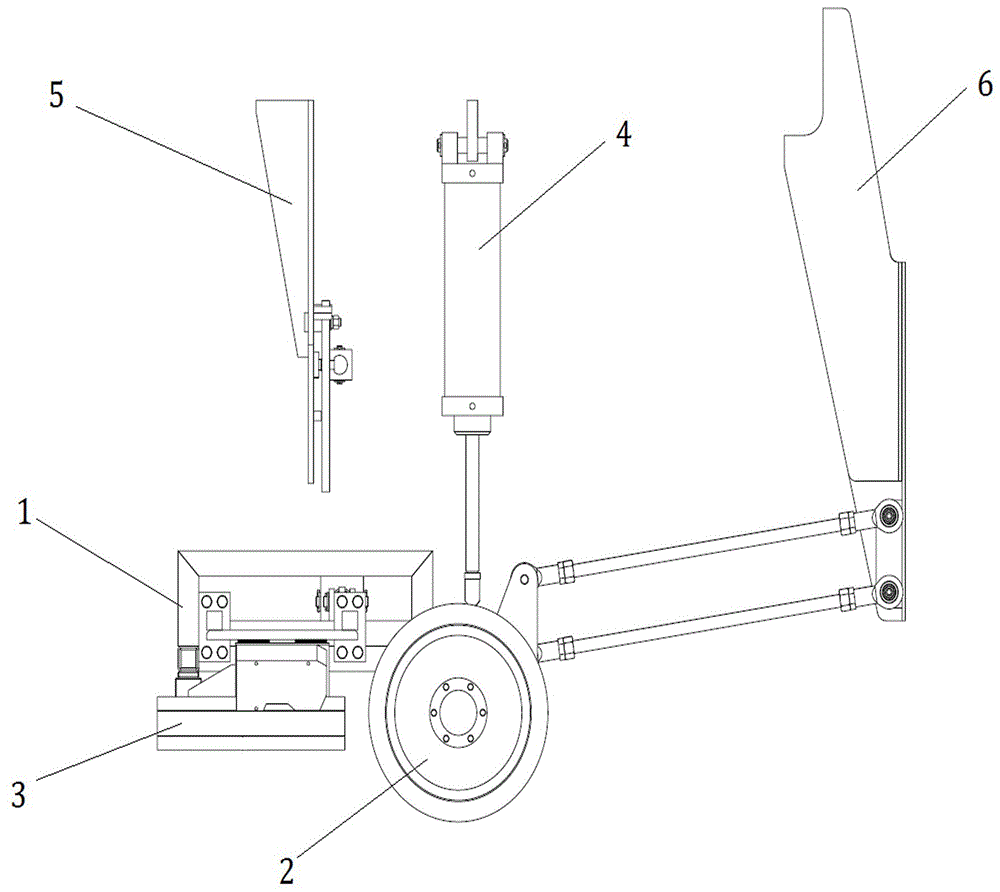

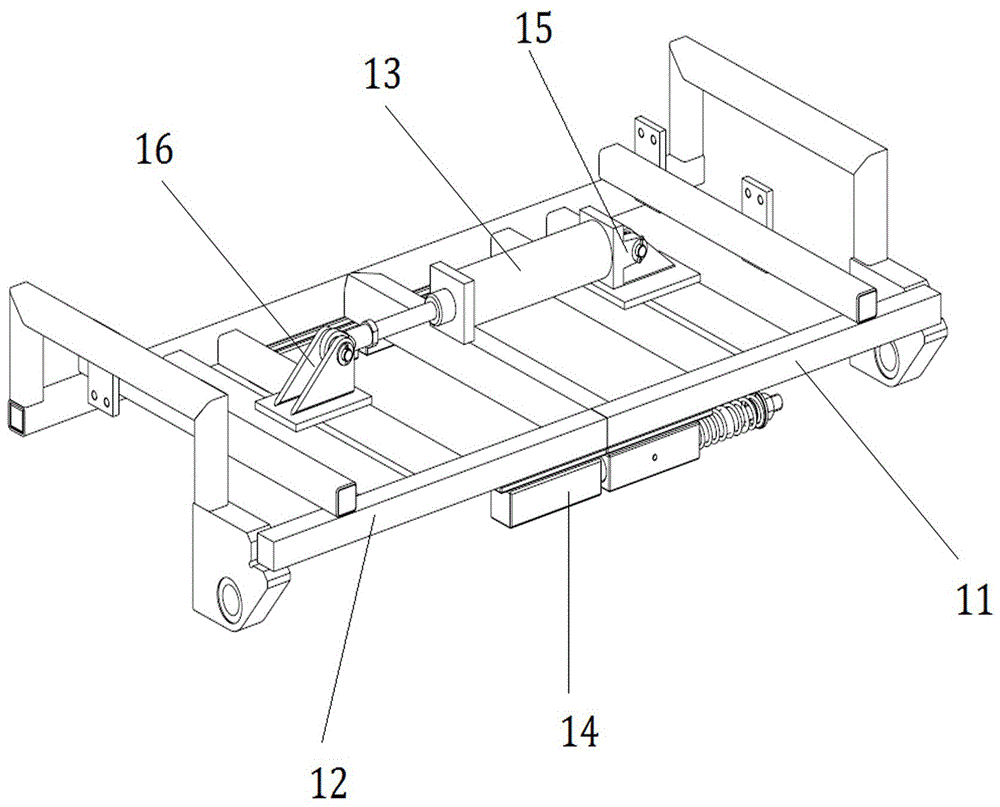

[0040] Attached below Figure 1-Figure 4 The preferred embodiment of the track detection trolley provided by the present invention is described.

[0041] figure 1 It is the front view of a track detection trolley provided by the embodiment of the present invention, figure 2 A side view of a track inspection trolley provided by an embodiment of the present invention, image 3 It is a schematic diagram of the detailed structure of a chassis 1 of a track detection trolley provided by an embodiment of the present invention. Such as figure 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com