Efficient special type centrifugal fan

A centrifugal fan, a special technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as large power consumption and harshness, and achieve the effect of saving energy, reducing motion vibration, and running stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

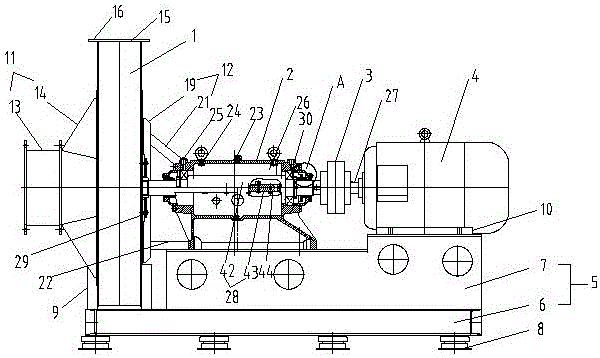

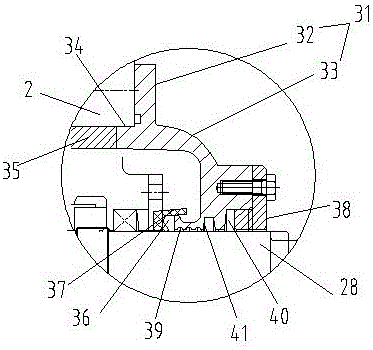

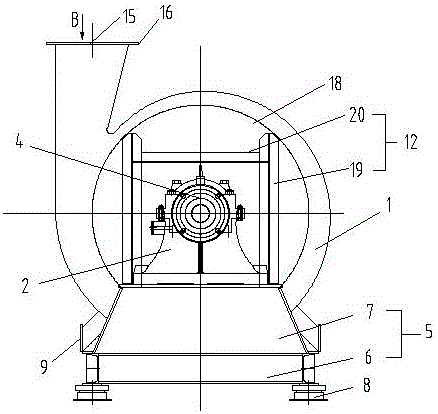

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] A high-efficiency special centrifugal fan, including a volute, a bearing box, a coupling, a motor and a base, wherein the volute, the bearing box and the motor are all arranged on the base, and the base includes a primary base and a secondary The first-stage seat, the bottom of the first-stage seat is provided with a number of supporting feet, the two sides of the first-stage seat and the volute are provided with support plates, the second-stage seat is L-shaped, and the side section is an isosceles trapezoid , a fixing plate is provided between the secondary base body and the motor;

[0025] One side of the volute is provided with an air inlet ring, and the other side is provided with a support frame. The air inlet ring includes an air inlet and several connecting plates. The connecting plates are triangular and arranged around the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com