Self-anchored perforated steel pipe supporting device and anchoring construction method thereof

A support device and construction method technology, applied in excavation, foundation structure engineering, construction, etc., can solve problems such as poor foundation pit support stability, achieve good support stability, enhance anchorage, and increase frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

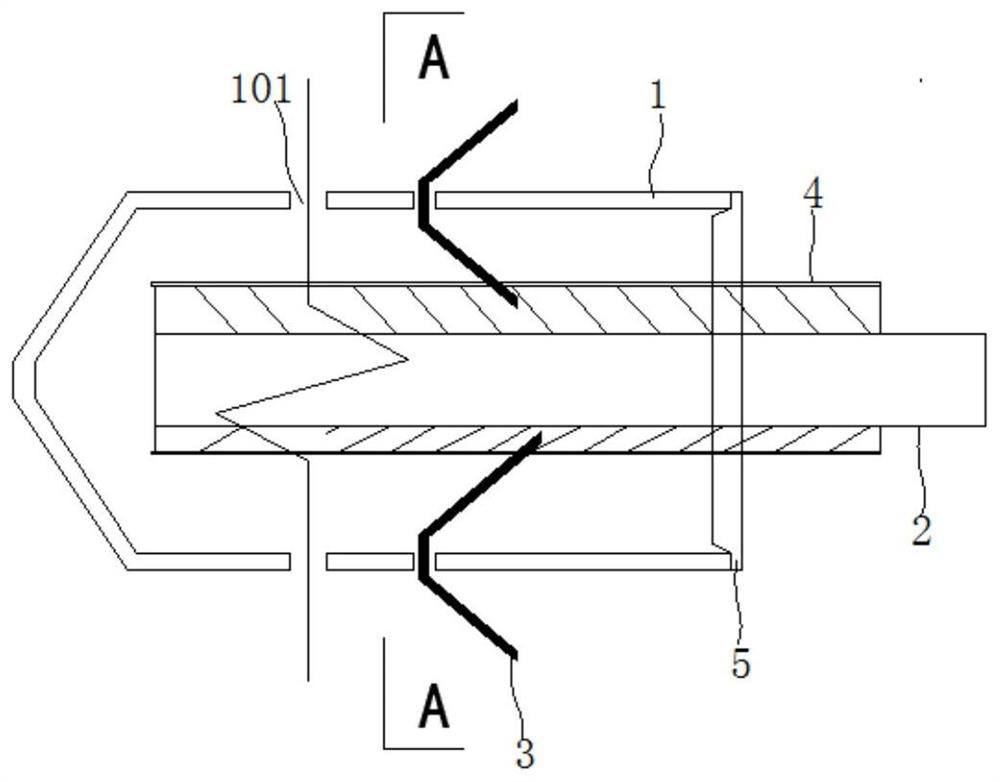

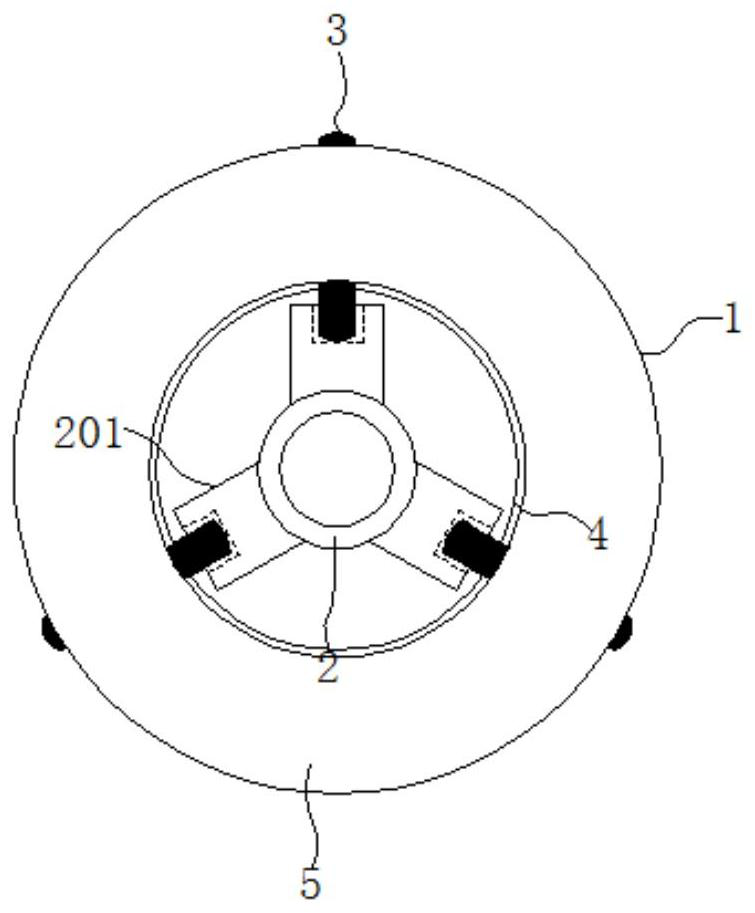

[0044] combine Figure 1-Figure 3 , a kind of self-anchored flower steel pipe supporting device of the present embodiment, comprises flower steel pipe 1, grouting pipe 2 and anchor bar 3, wherein, the surface of flower steel pipe 1 is processed with perforation 101 for grout to pass through, anchor bar 3 It can be movably installed in the perforation 101, one end of which is located inside the flower steel pipe 1, and the other end protrudes to the outside of the flower steel pipe 1. The grouting pipe 2 is set inside the flower steel pipe 1 and can move freely along the length of the flower steel pipe 1. The surface of the grouting pipe 2 is provided with serrations 201 distributed along its length at intervals and matched with the anchor bars 3 .

[0045] Such as Figure 7 As shown, the anchor tendon 3 is composed of an anchoring section 301, a connecting section 302 and a load-bearing section 303. Type structure, the load-bearing section 303 pushes the anchor bars 3 to mo...

Embodiment 2

[0048] The structure of the self-anchoring flower steel pipe supporting device of this embodiment is basically the same as that of Embodiment 1, the main difference is that in this embodiment, the surface of the grouting pipe 2 is provided with multiple serrations 201 evenly spaced along its circumference, The surface of the flower pipe is provided with a plurality of anchor bars 3 corresponding to each sawtooth 201 respectively, and the distance between adjacent sawtooths in the same sawtooth 201 is 20-30cm, and the width of the sawtooth is 20-30cm, which is conducive to further ensuring The effect of supporting the surrounding foundation. Specifically, in this embodiment, the serrations 201 are cast iron serrations with a width of 20 cm, and the surface of the grouting pipe 2 is provided with three serrations 201 evenly and symmetrically distributed. Arranged evenly, the central angle between them is 120°, which can further increase the reverse gripping ability of the flower...

Embodiment 3

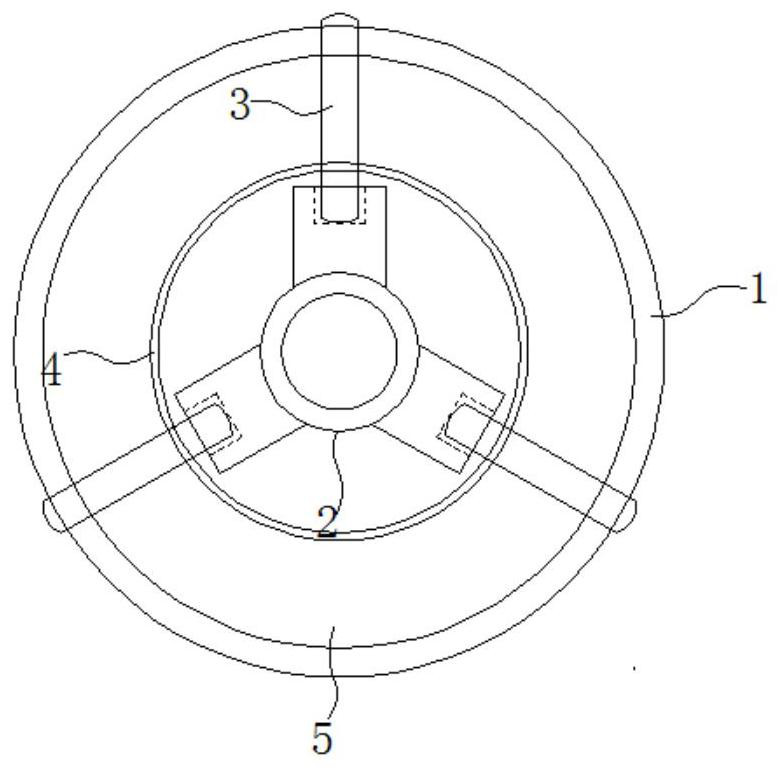

[0057] A kind of self-anchor flower steel pipe supporting device of this embodiment, its structure is basically the same as embodiment 2, and its difference mainly is: the sleeve pipe 4 of this embodiment adopts PVC pipe, and its thickness is 3-5mm, and flower steel pipe 1 is Cylindrical hollow pipe structure, and its other end opposite to the plug cap is processed into a conical structure, the cone angle is 105°-120°, so the support device of this embodiment can also be directly driven into the soil layer, and There is no need to use other external lead hole equipment for lead hole construction, which greatly reduces the construction period and improves construction efficiency (the specific principle: stir the soil layer in the forward direction through the cone angle, and then expand the anchor hole again through the anchor bar, so that the whole device can easily into the soil). The inner diameter and thickness of the flower steel pipe 1 are determined according to the draw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com