An improved centrifugal fan rotating stall experimental device and its detection method

A rotating stall and experimental device technology, applied in mechanical equipment, engine control, machine/engine, etc., can solve the problems of blade high stress point fatigue, surge, accident hidden danger, etc., to reduce the interference signal component, improve the accuracy, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, will not be described in detail here.

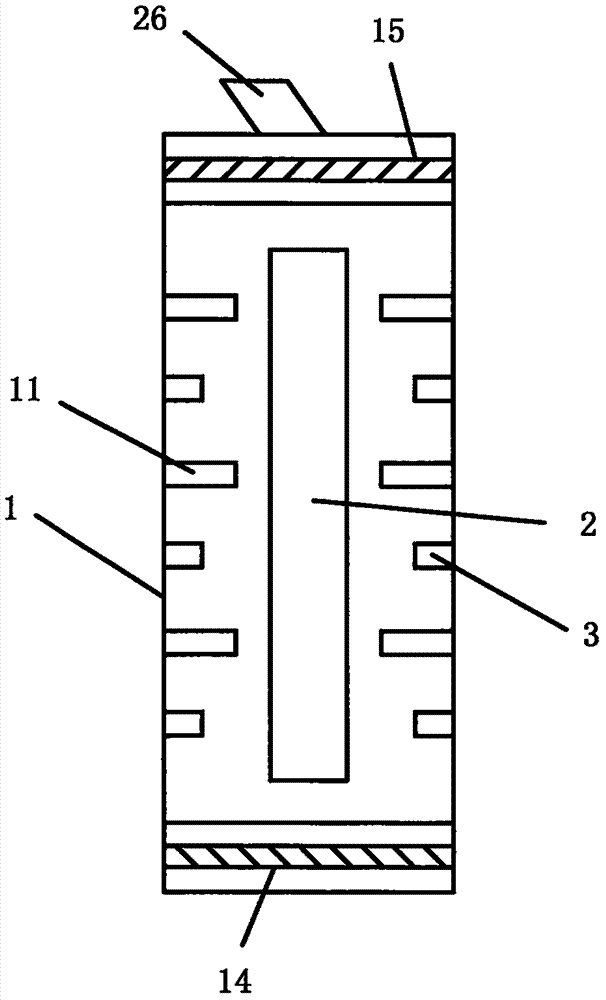

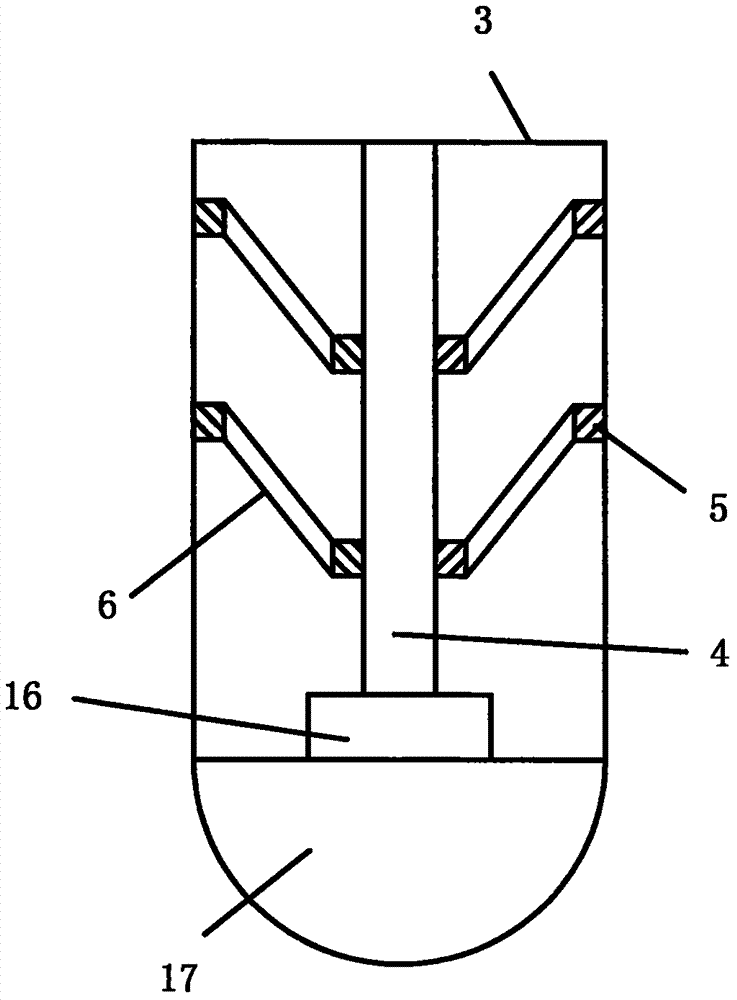

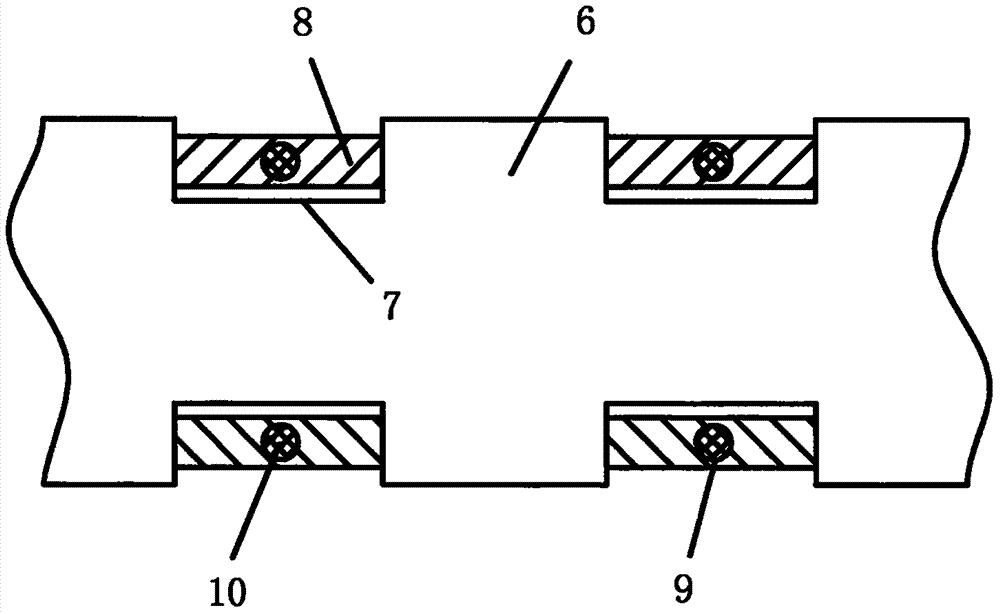

[0030] refer to Figure 1-7 , this embodiment includes a volute 1, an impeller 2 is installed inside the volute 1, several first nozzles 3 are evenly arranged on the inner surface of the volute 1, a base 16 is arranged at the bottom of the first nozzle 3, and the inside of the first nozzle 3 A first hydraulic rod 4 is installed in the axial direction, and the first hydraulic rod 4 is installed on the base 16. Several first baffles 6 are connected between the first hydraulic rod 4 and the inner wall of the first nozzle 3 through the first spring body 5 , the first baffle plate 6 is provided with a diversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com