Optimization control method of temperature gradient inside rotary kiln

A gradient optimization, internal temperature technology, applied in rotary drum furnaces, furnaces, lighting and heating equipment, etc., can solve problems such as uneven temperature distribution, and achieve the effect of stabilizing product quality and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

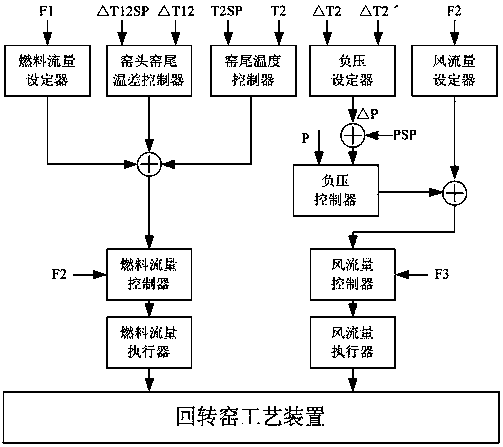

[0011] The raw material flow rate F1 is used as the input of the fuel flow setter, and the output of the setter is a function of the input variable F1, which is set according to the design data or operating experience; △T12 is the temperature difference between the kiln head and the kiln tail, △T12SP is the setting value of the temperature difference controller at the kiln head and kiln tail, T2SP and T2 are the setting value and measured value of the kiln tail temperature controller respectively, the output of the fuel flow setter and the output of the temperature difference controller at the kiln head and kiln tail, and the kiln tail The temperature controller outputs the sum of the three as the set value of the fuel flow controller, and the fuel flow F2 as the measured value of the fuel flow controller. Each controller adopts the PID control algorithm to realize the closed-loop control of the fuel flow; the kiln head kiln The value range of the ratio P of the tail temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com