Control method for full-power power shifting of hydraulic-mechanical stepless transmission

A technology of stepless transmission and hydraulic machinery, applied in the direction of mechanical equipment, transmission devices, fluid transmission devices, etc., can solve problems such as power interruption, output speed fluctuation, constant displacement hydraulic component speed mutation, etc., to eliminate speed fluctuation and power Interruption, reduction of sliding wear, and improvement of the quality of changing sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

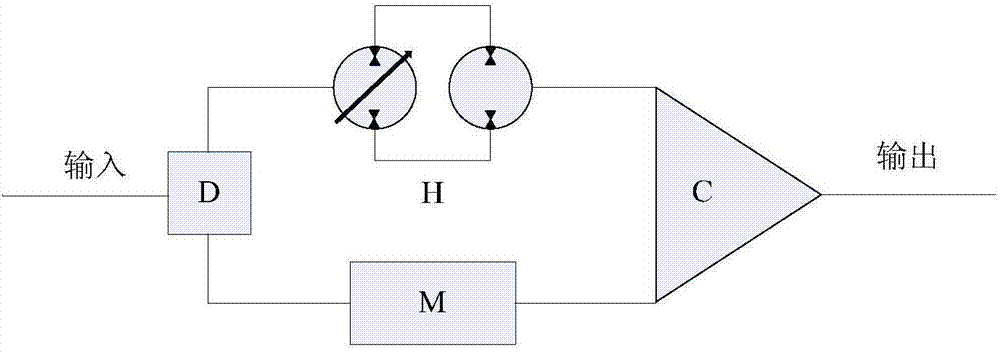

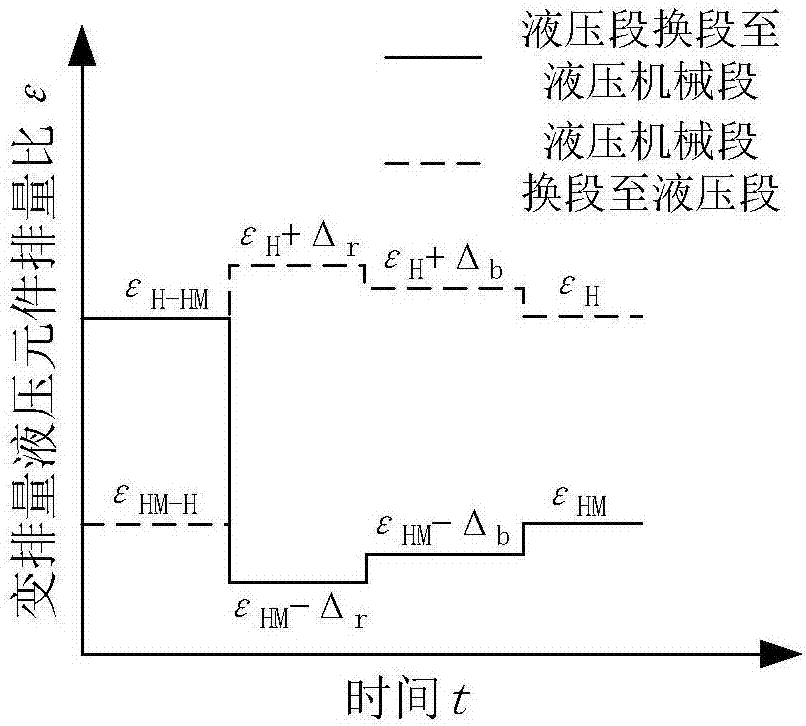

[0030] The core of the present invention is to provide a hydraulic mechanical stepless transmission full-power power shift control method, the method enables the hydraulic machine to complete the smooth transition from the current stage to the target stage when the two clutches are combined and overlapped, and realizes power transfer. The power can be transmitted normally during the section process, and the full power power can be changed.

[0031] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

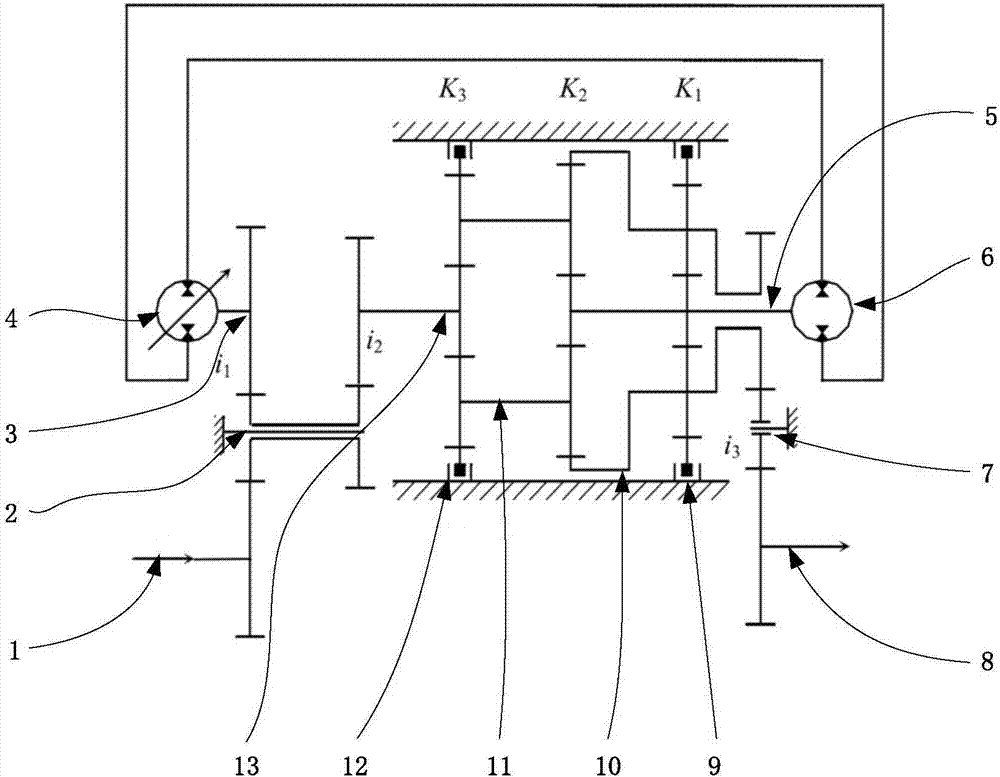

[0032] In this example, the figure 2 A certain arithmetic differential two-stage hydraulic-mechanical stepless transmission device shown implements full-power power shifting control. The transmission device can be divided into two working conditions, the hydraulic section and the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com