a fusible rod

A fusible sheet, fusing technology, applied in safety valves, engine components, balance valves, etc., can solve the problems of fusible sheet fusing lag, inability to play fire prevention, leakage, etc., and achieve the effect of small thermal expansion and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

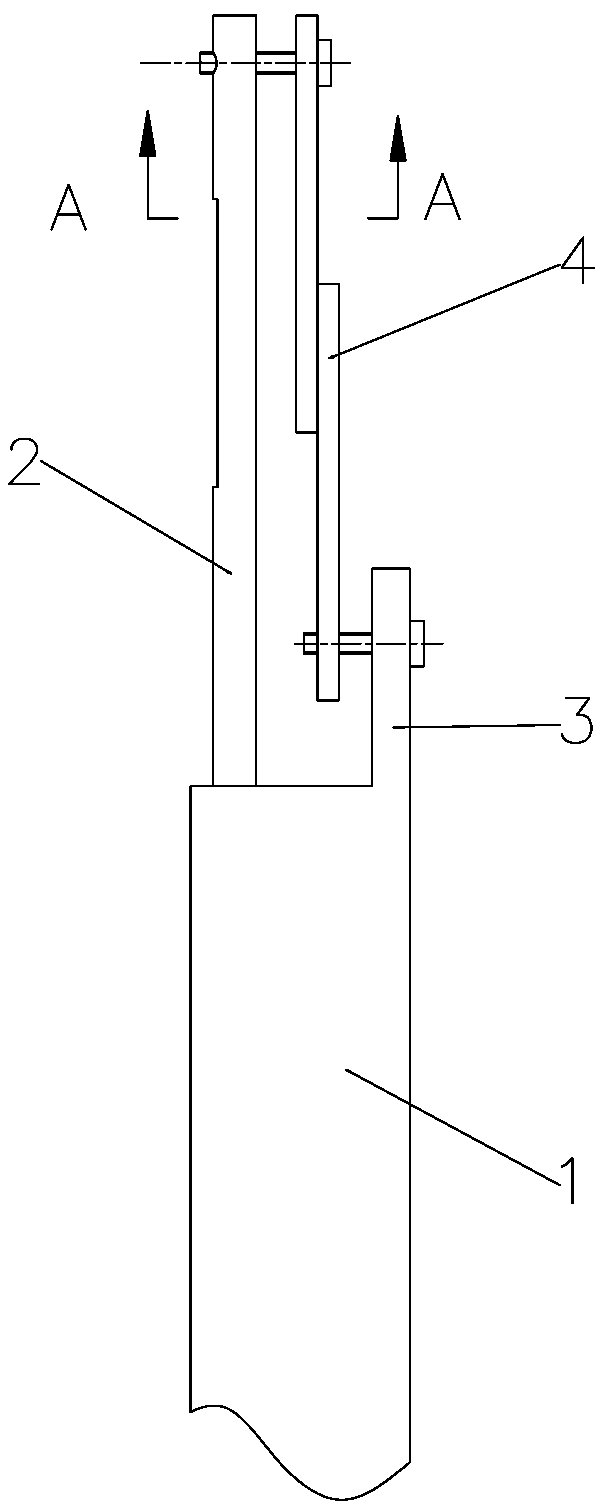

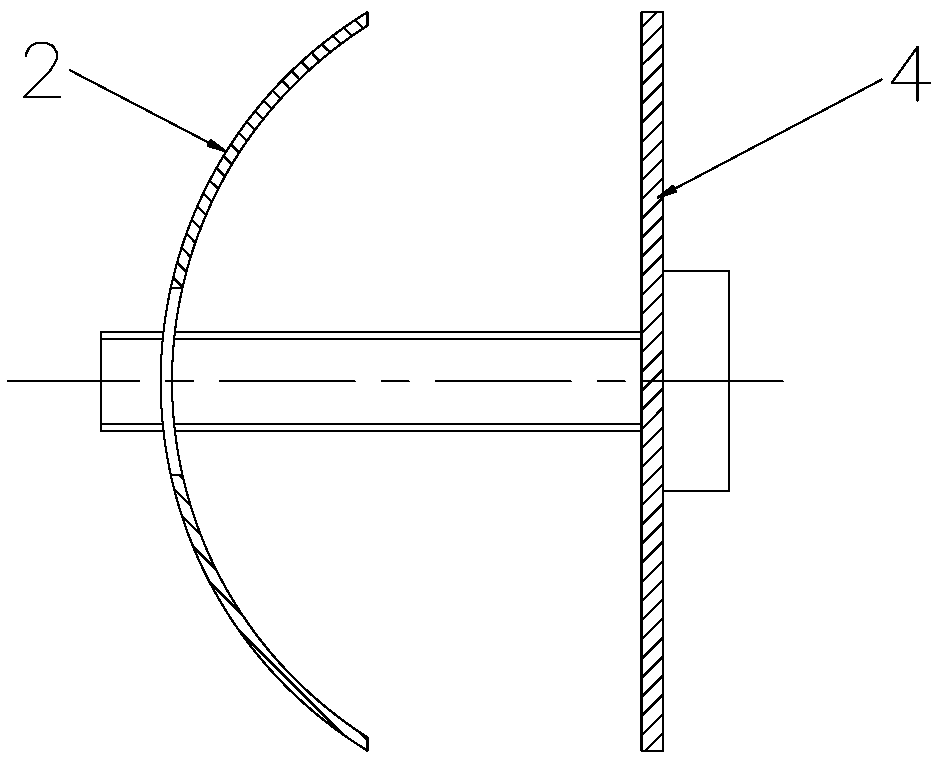

[0029] Such as image 3 Shown is a schematic structural diagram of the fusible rod embodiment 1 of the present invention. The fusible rod of this embodiment includes a fuse seat 1, a core rod slidingly fitted inside the fuse seat 1, a heat-gathering member 5 is provided at one end of the core rod, and a heat-gathering member 5 is provided on the fuse seat 1 corresponding to the heat-gathering member 5 The connecting piece 3 is provided with a fusible part 6 between the connecting piece 3 and the heat collecting part 5 , and the two ends of the fusible part 6 are respectively connected with the heat collecting part 5 and the connecting piece 3 . A heat collecting cavity 7 is provided between the heat collecting part 5 and the fusible part 6 in this embodiment, the width of the heat collecting part 5 is greater than the width of the fusible part 6, and the two sides of the heat collecting part 5 are connected with the fusible part 6 respectively. A heat-gathering gap 8 for dire...

Embodiment 2

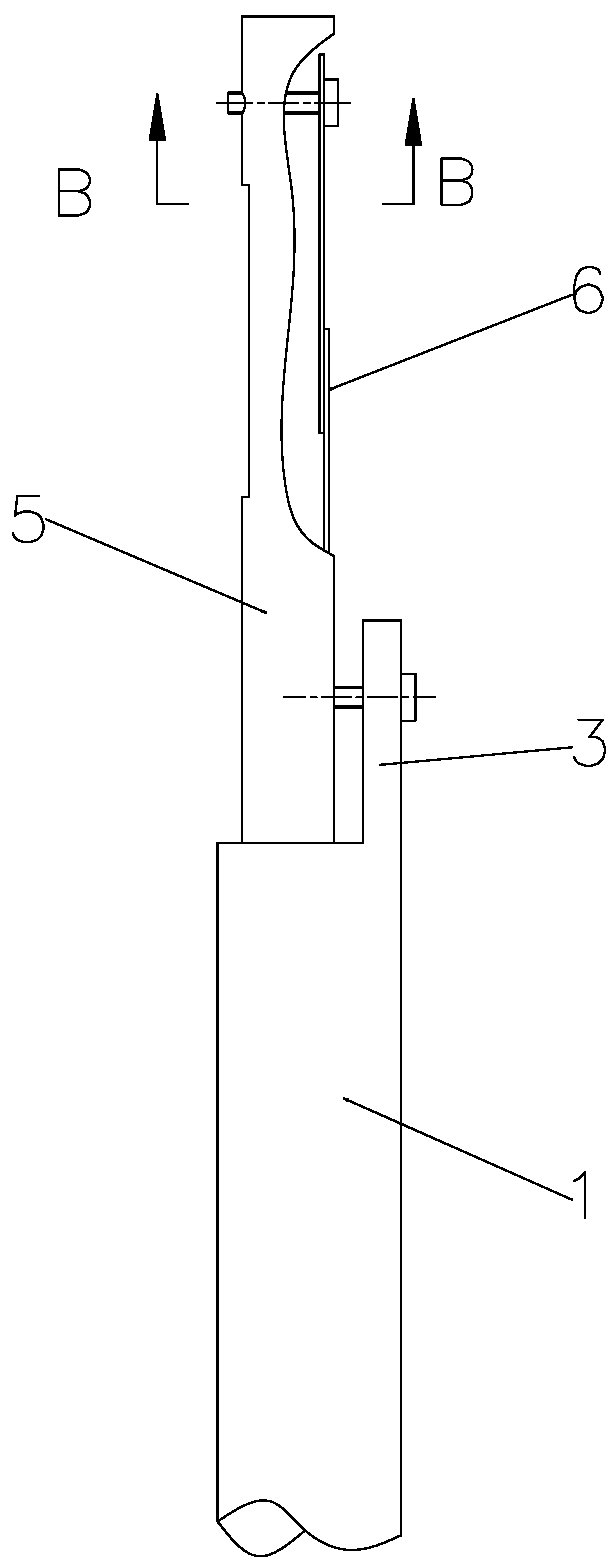

[0034] Such as Figure 5 Shown is a schematic structural diagram of the fusible rod embodiment 2 of the present invention. The fusible rod of this embodiment includes a fuse seat 1, a core rod slidingly fitted inside the fuse seat 1, a heat-gathering member 5 is provided at one end of the core rod, and a heat-gathering member 5 is provided on the fuse seat 1 corresponding to the heat-gathering member 5 The connecting piece 3 is provided with a fusible part 6 between the connecting piece 3 and the heat collecting part 5 , and the two ends of the fusible part 6 are respectively connected with the heat collecting part 5 and the connecting piece 3 . A heat collecting cavity 7 is provided between the heat collecting part 5 and the fusible part 6 in this embodiment, the width of the heat collecting part 5 is greater than the width of the fusible part 6, and the two sides of the heat collecting part 5 are connected with the fusible part 6 respectively. There is a heat-gathering gap ...

Embodiment 3

[0039] Such as Figure 6Shown is a schematic structural diagram of the fusible rod embodiment 2 of the present invention. The fusible rod of this embodiment includes a fuse seat 1, a core rod slidingly fitted inside the fuse seat 1, a heat-gathering member 5 is provided at one end of the core rod, and a heat-gathering member 5 is provided on the fuse seat 1 corresponding to the heat-gathering member 5 The connecting piece 3 is provided with a fusible part 6 between the connecting piece 3 and the heat collecting part 5 , and the two ends of the fusible part 6 are respectively connected with the heat collecting part 5 and the connecting piece 3 . A heat collecting cavity 7 is provided between the heat collecting part 5 and the fusible part 6 in this embodiment, the width of the heat collecting part 5 is greater than the width of the fusible part 6, and the two sides of the heat collecting part 5 are connected with the fusible part 6 respectively. There is a heat-gathering gap 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com