Hearth body for solar heat collector

A solar collector and furnace technology, which is used in solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of poor thermal insulation effect, easy to solidify and block pipes, etc., and achieves good thermal insulation effect, stable and reliable structure, The effect of good support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

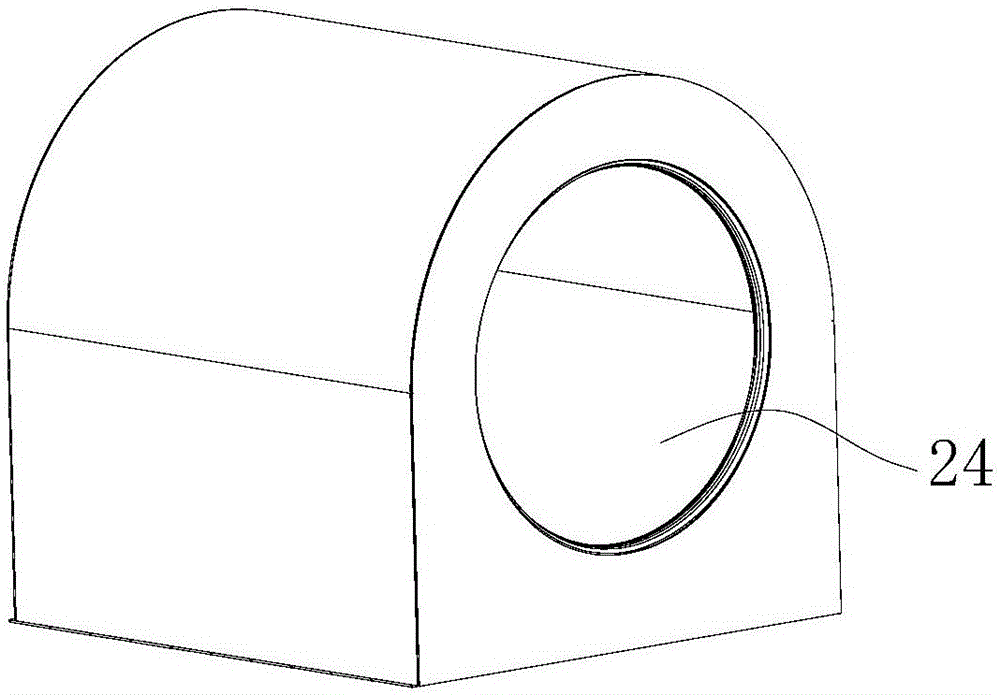

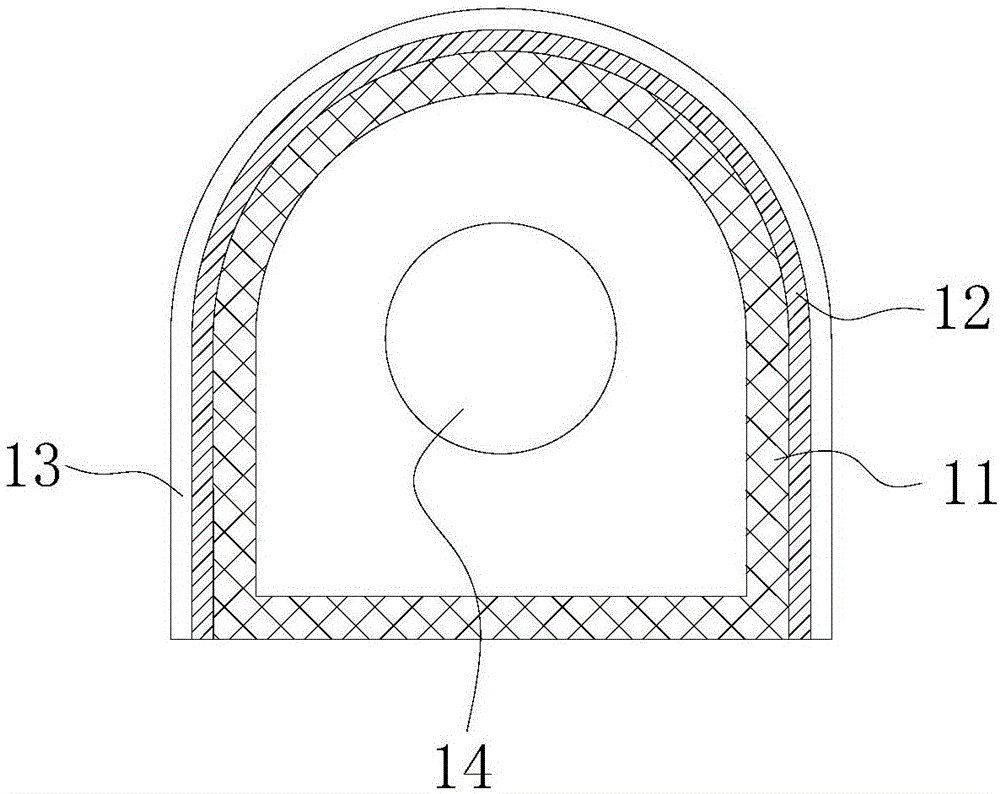

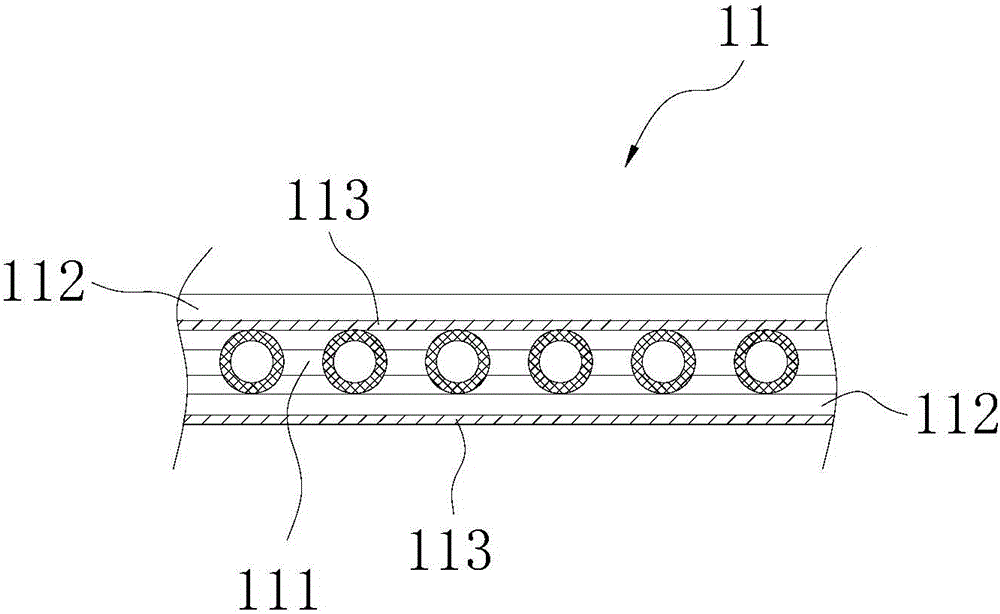

[0018] Such as Figure 1 to Figure 2 As shown, the furnace body includes a vacuum heat insulation cavity 11, a composite heat insulation layer 12 arranged on the periphery of the vacuum heat insulation cavity 11, and an insulation shell 13 covering the periphery of the composite heat insulation layer 12; the vacuum heat insulation cavity 11 It is composed of several vacuum insulation panels, such as image 3 As shown, the vacuum insulation panel includes a first metal support 111, and a heat insulation panel 112 arranged on the front and back sides of the first metal support 111 for forming a vacuum cavity; Figure 4 As shown, the composite thermal insulation layer 12 includes an aluminum silicate wool layer 121 and an aluminum foil layer 122 disposed on both sides of the aluminum silicate wool lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com