Motor operation monitoring apparatus

A technology of operation monitoring and electric motors, which is applied in the direction of motor generator testing, measuring devices, measuring electricity, etc. It can solve the problems of double-motor or multi-motor drive system monitoring loopholes, operators cannot find and deal with them in time, and operating current increases. , to achieve the effect of reducing inspection frequency, reducing troubleshooting time, and increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

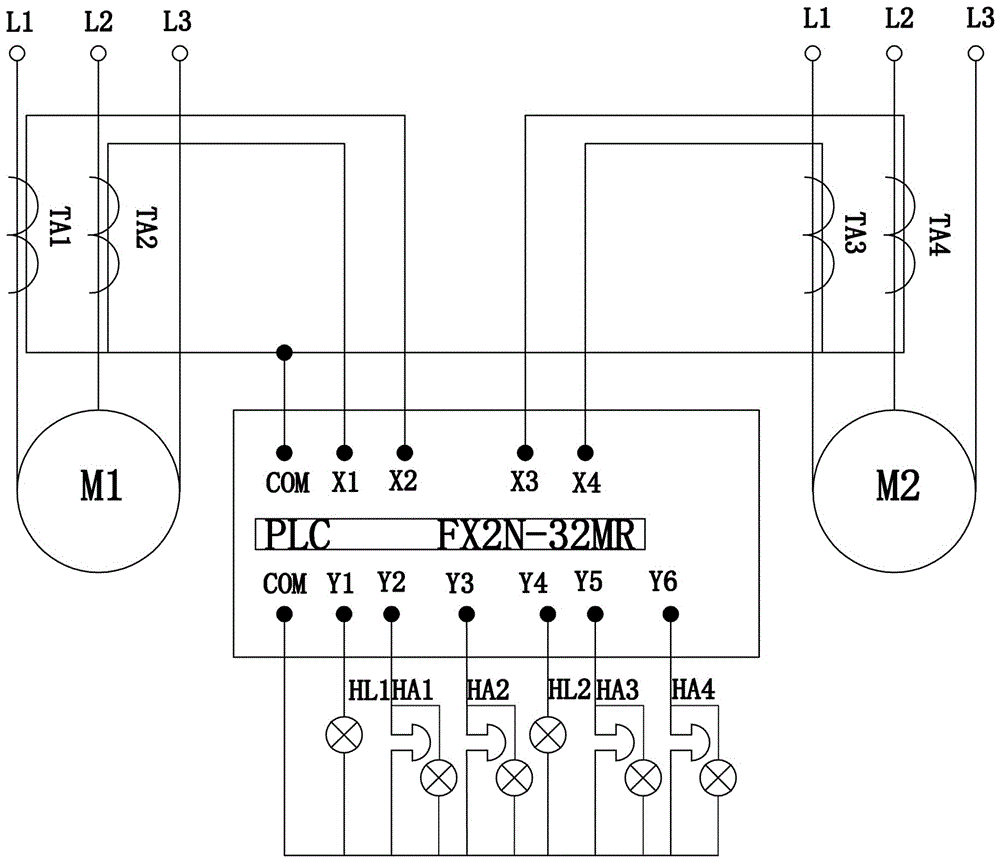

[0016] figure 1 Schematic diagram of the motor running monitoring device. Among them, TA1, TA2, TA3 and TA4 are current sensing switches; PLC is the programmable controller of Mitsubishi FX2N series; HL1 and HL2 are the motor running indicators of motor M1 and motor M2 respectively; HA1 and HA2 are the motor overload of motor M1 respectively The buzzer and the motor failure buzzer, HA3 and HA4 are respectively the motor overload buzzer and the motor failure buzzer of the motor M2.

[0017] The motor operation monitoring device can monitor the operation status of each motor in the dual-motor or multi-motor drive system in real time, and give an alarm in time when there is an abnormality, so as to prevent the failure of one motor and cause another motor or several motors to burn out. Bad. The device is composed of a current sensing switch, a programmable controller, an alarm indicating element, etc. If it is used underground, the device can be installed in an explosion-proof s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com