Touch panel, manufacturing method thereof, driving method, and touch display device

A touch panel and touch electrode technology, applied in the fields of touch panel and its manufacturing method, touch display device, and driving method, can solve the problem of inability to detect the size of touch pressure, achieve three-dimensional touch detection, optimize touch Function, realize the effect of touch position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

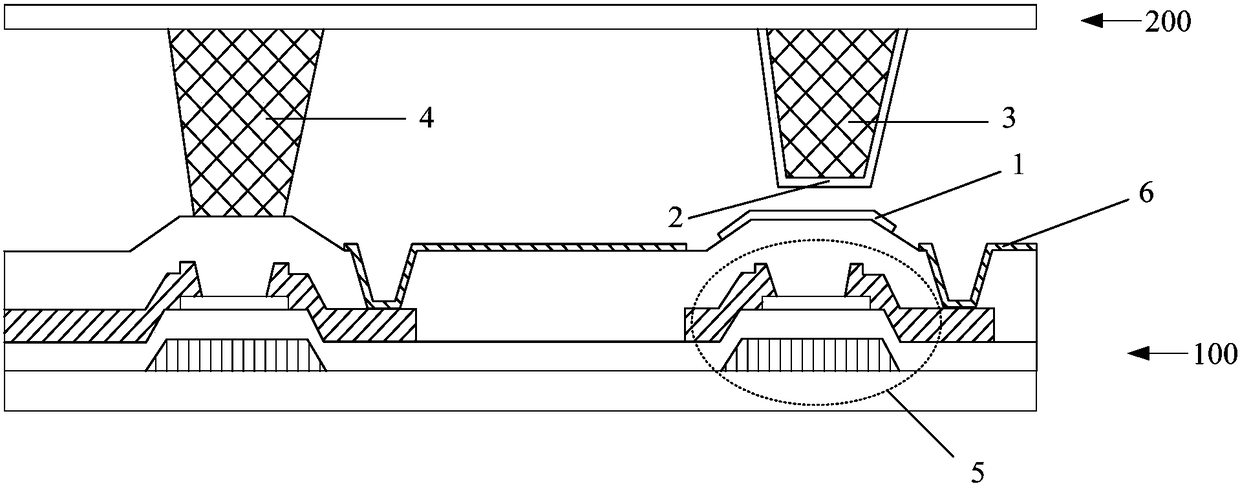

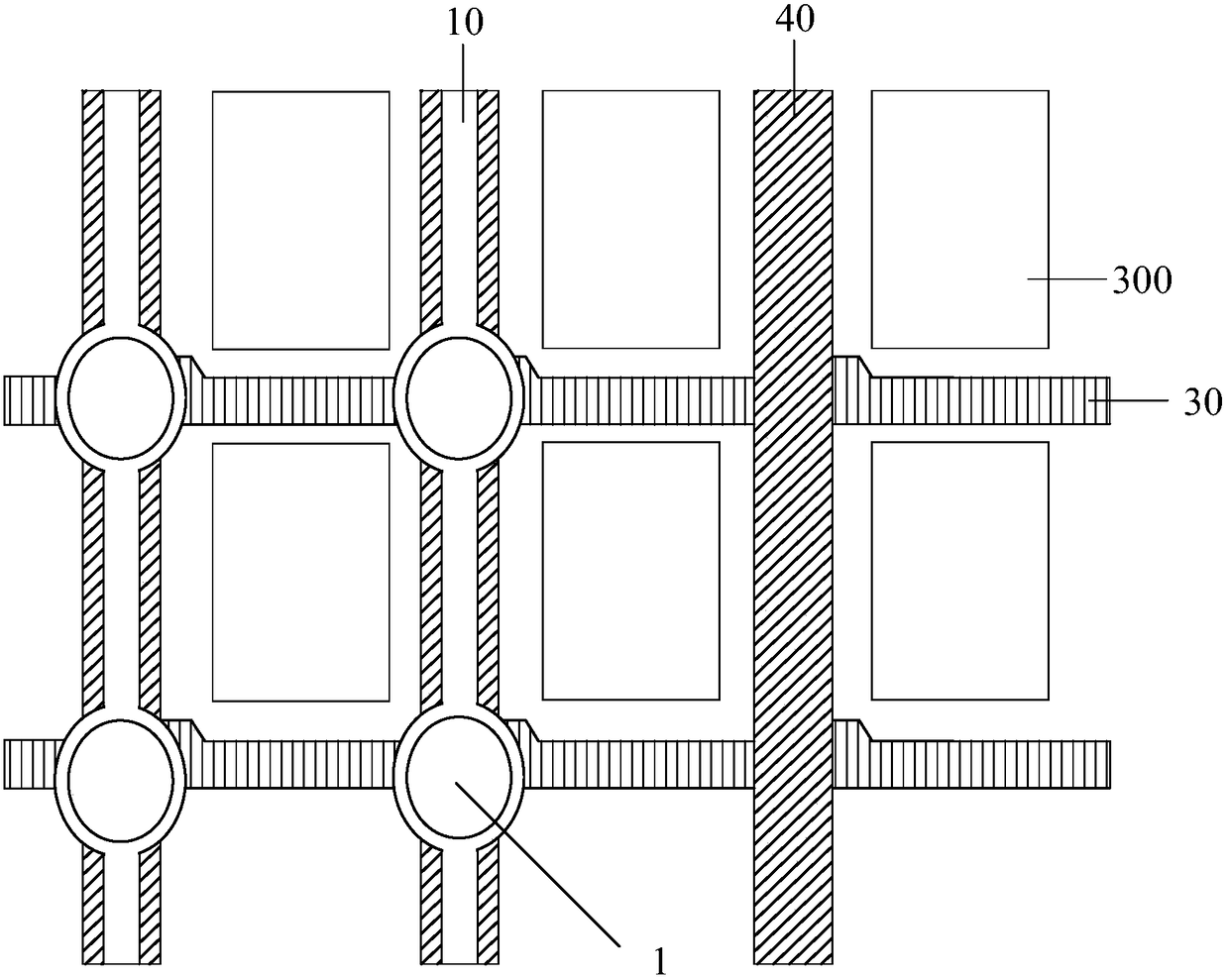

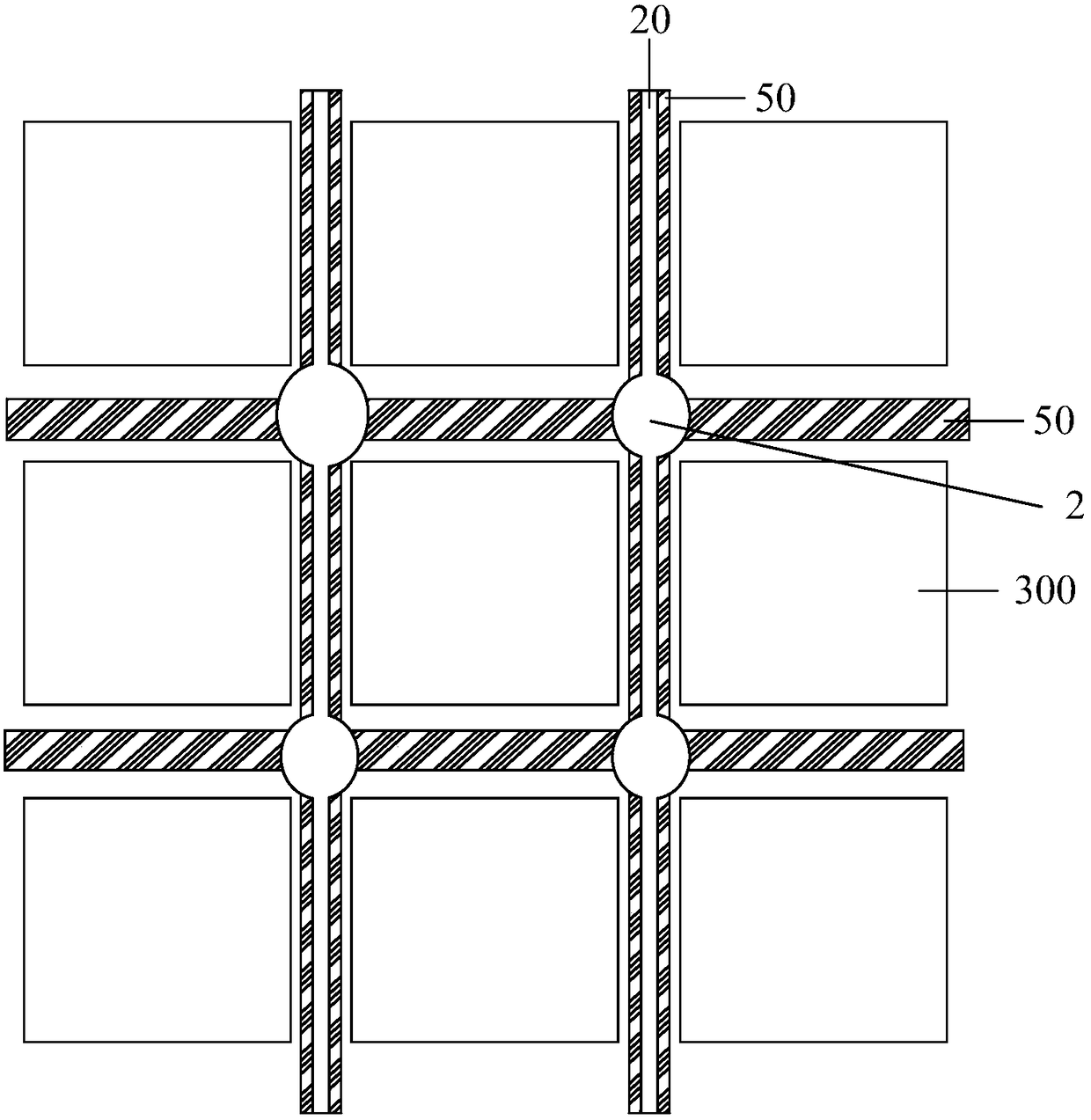

[0029] Such as figure 1 As shown, this embodiment provides a touch panel for detecting the magnitude of the touch pressure. The touch panel includes a first substrate 100 and a second substrate 200 opposite to each other, as well as a first touch electrode 1 , a second touch electrode 2 and a plurality of posts 3 . The first touch electrodes 1 are disposed on the first substrate 100 , the pillars 3 are disposed on the second substrate 200 , and there is a certain distance between the pillars 3 and the first substrate 100 . The second touch electrode 2 is arranged on the pillar 3, and the second touch electrode 2 corresponds to the first touch electrode 1 to form a detection capacitor, and the magnitude of the touch pressure is determined according to the capacitance change of the detection capacitor.

[0030] The specific detection principle is: when the touch panel is touched, the distance between the plurality of pillars 3 and the first substrate 100 decreases, and the dist...

Embodiment 2

[0064] This embodiment provides a touch display device, which includes the touch panel in Embodiment 1, so as to detect the magnitude of the touch pressure. At the same time, it can also realize the detection of the touch position, realize three-dimensional touch detection, optimize the touch function of the touch display device, and overcome the problem that the touch function is limited by the size of the display screen.

[0065] The driving method of the above-mentioned touch display device includes:

[0066] Apply an excitation signal to the first touch electrode of the touch panel, and detect the sensing signal on the second touch electrode, and calculate the detection capacitance between the first touch electrode and the second touch electrode according to the sensing signal The change in capacitance of the detection capacitor, and determine the magnitude of the touch pressure according to the change in capacitance of the detection capacitor.

[0067] When the touch pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com