Multi-parameter temperature measuring type electric fire monitoring system

A technology for electrical fire and monitoring systems, applied in electrical fire alarms and other directions, can solve problems such as increased engineering equipment costs, limited protection scope, unstable work, etc., to improve electrical fire response capabilities and alarm accuracy, improve Engineering suitability, effect of increased sensitivity level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

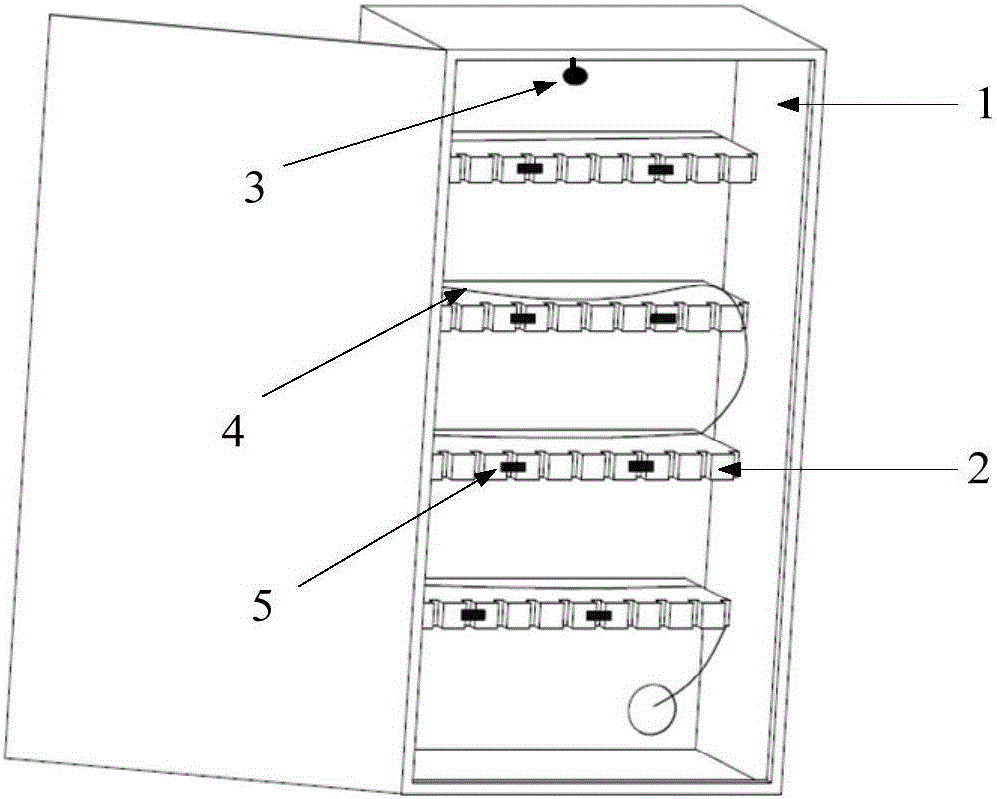

[0025] The specific embodiment of the present invention will be further described in detail in conjunction with the accompanying drawings.

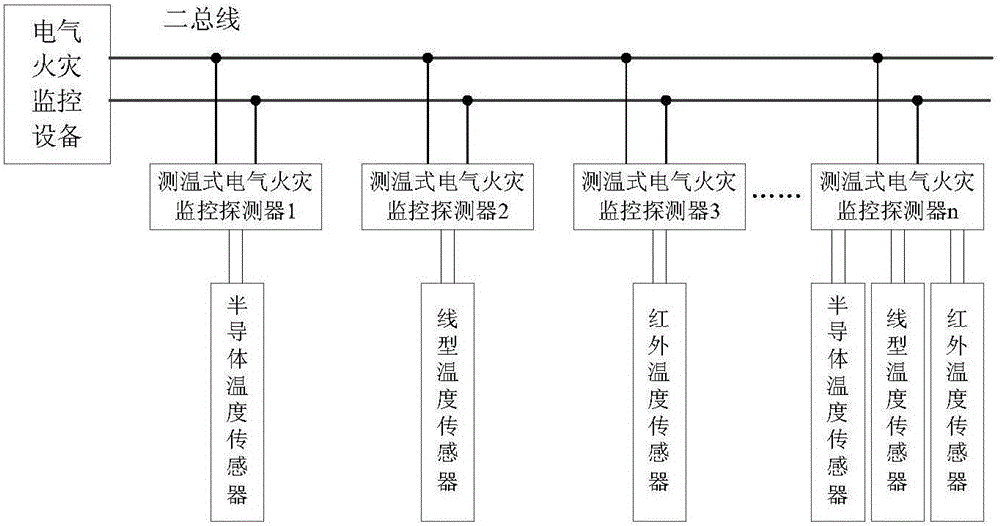

[0026] See attached figure 1 A multi-parameter temperature-measuring electrical fire monitoring system comprises electrical fire monitoring equipment, a temperature-measuring electrical fire monitoring detector and a temperature sensor.

[0027] The temperature-measuring electrical fire monitoring detector is connected to at least one temperature sensor, and the type of temperature sensor is not limited to one; temperature sensors include semiconductor temperature sensors, linear temperature sensors, infrared temperature sensors, etc.

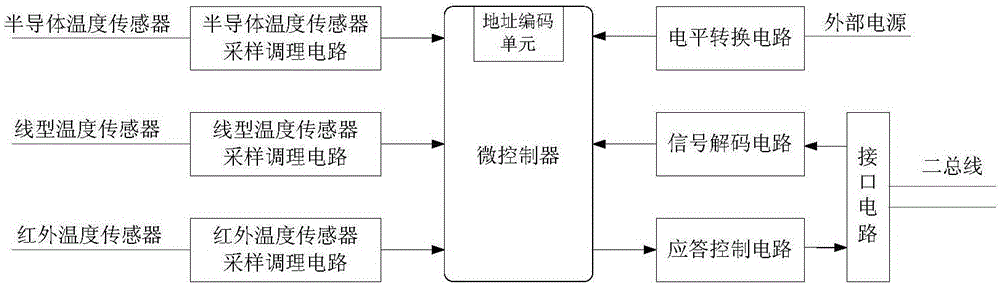

[0028] See attached figure 2 , Temperature-measuring electrical fire monitoring detector main circuit, including microcontroller circuit, level conversion circuit, interface circuit, signal decoding circuit, response control circuit, sampling conditioning circuit.

[0029] The temperature-measuring elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com