High-water resistance control cable

A technology for controlling the performance of cables, which is applied in the field of control cables with high water-resistance performance. It can solve the problems of increased cable maintenance costs and safety risks, poor water-resistance effect, cable breakdown and scrapping, etc., and achieves good anti-extrusion and tensile effects. , good weather resistance, good cushioning and anti-vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

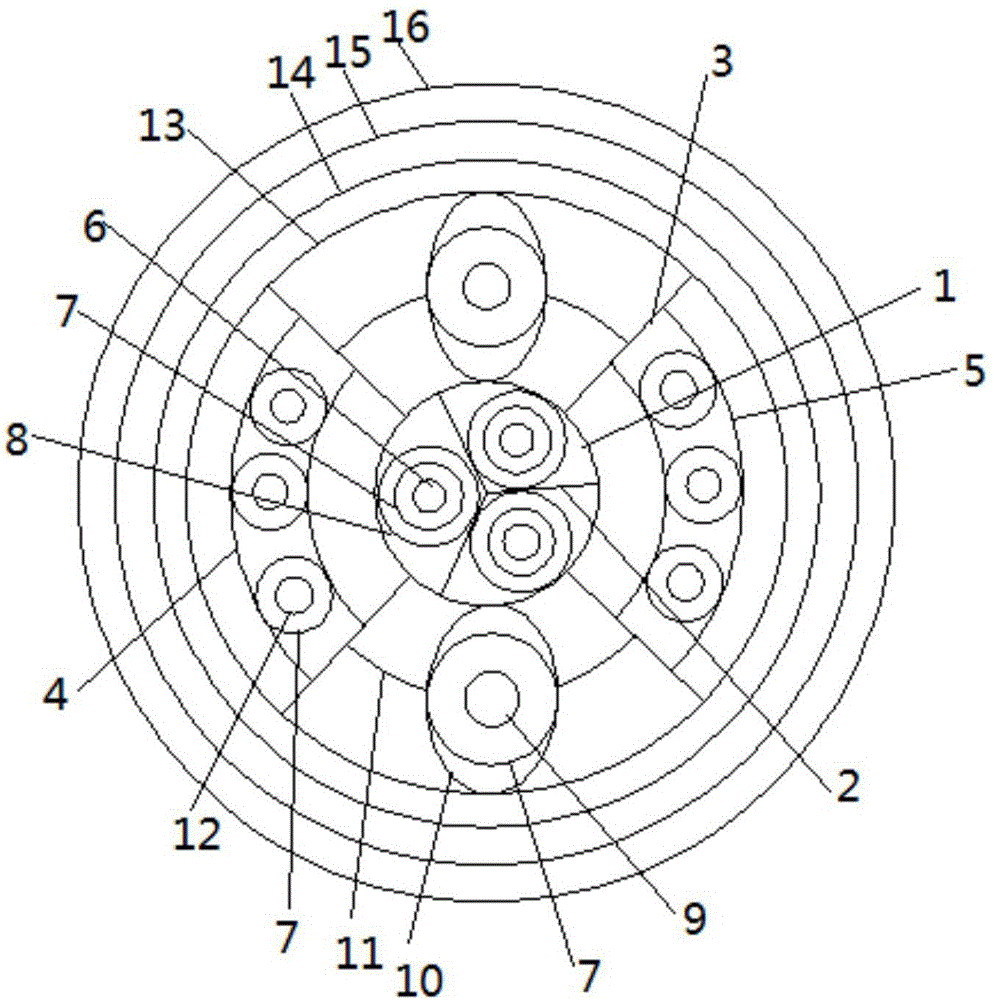

[0014] like figure 1 As shown, a control cable with high water resistance performance includes a circular reinforced insulating tube 1, and a Y-shaped insulating partition 2 is arranged inside the reinforced insulating tube 1, and the outer wall of the insulating reinforced tube 1 is uniformly formed Radial shape is provided with 4 insulation partitions 3, two arc partitions 4 are connected between the two insulation partitions 3 on the left side, and two arc partitions 4 are connected between the two insulation partitions 3 on the right side. Shaped partition 2 5, three main cores are arranged between the Y-shaped insulating partition 2 and the inner wall of the insulation strengthening tube 1, and the main cores include a main conductor 6 and three wires coated on the outside of the main conductor 6 in turn. Fluoropropyl fluorosilicone rubber insulating layer 7 and semi-conductive shielding layer 8 are respectively provided with control wire cores on the upper side and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com